Construction method for vibrating sunken tube construction secant pile wall

A construction method and the technology of occlusal piles, which are applied in sheet pile walls, foundation structure engineering, construction, etc., can solve the problems of insufficient drainage of water in holes, influx of groundwater into holes, and inability to fetch soil by punching and grabbing, so as to reduce construction costs The effect of shortening the construction period, speeding up the construction progress, and improving the quality of the pile body

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The present invention is further described below, but protection scope of the present invention is not limited thereto:

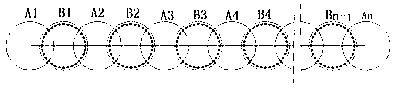

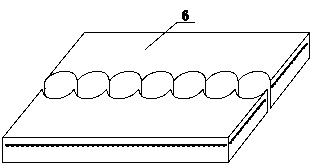

[0037] Such as Figure 1-2 As shown, the occlusal pile of the present invention is constructed by means of a single pile, and then after cutting off a part of the plain concrete piles that have been constructed, a steel cage concrete pile is constructed on two plain concrete piles, so that there is a gap between the piles and the piles. A continuous system is formed. The reinforced concrete pile bears the active earth pressure during the excavation of the foundation pit. The plain concrete pile acts as a water-stop curtain to prevent the groundwater outside the pit from entering the pit. The construction principle of the present invention is to construct the A pile first, and then construct the B pile In the figure, A1, A2, A3, A4...An are plain concrete piles, B1, B2, B3, B4...Bn-1 are reinforced concrete piles, where n is a natural number, and its ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Wall thickness | aaaaa | aaaaa |

| Pile diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com