Building sand screening device

A sand screener and construction technology, which is applied in the direction of filter screen, chemical instrument and method, solid separation, etc., can solve the problems of laborious screen screening, low screening efficiency, etc., and achieve the effect of preventing clogging, convenient screening, and convenient movement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

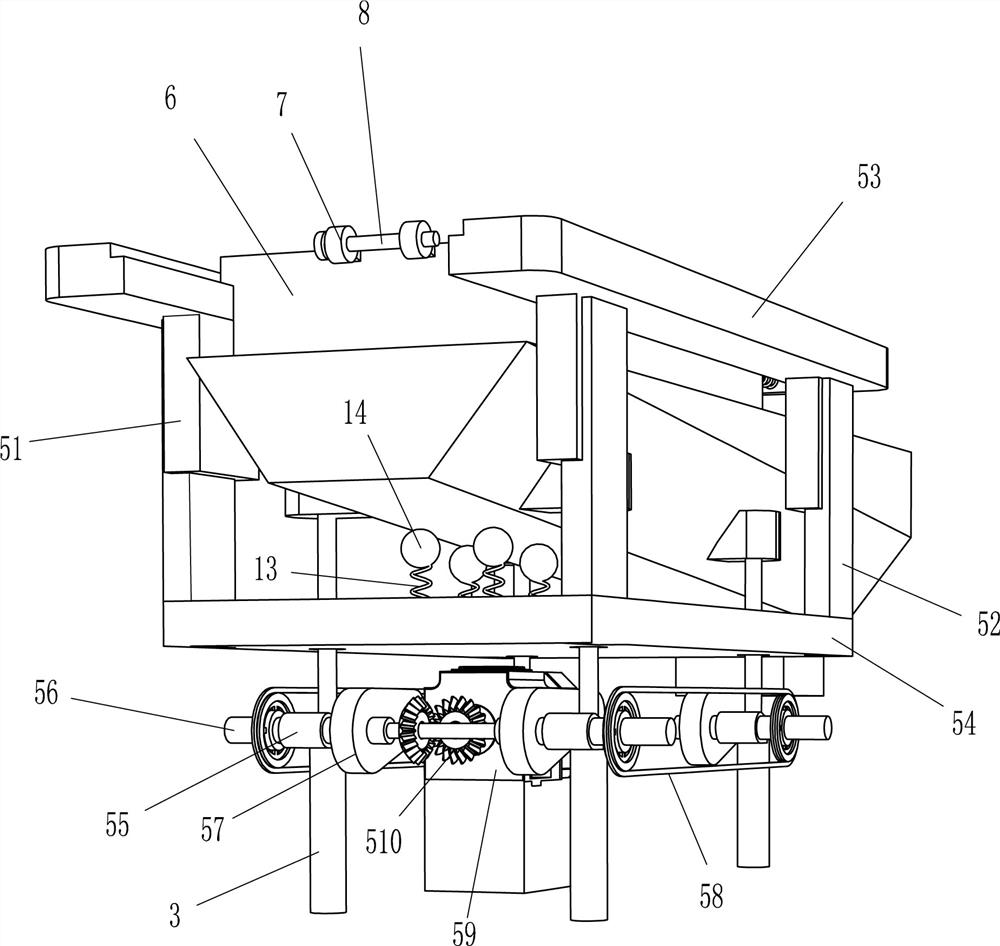

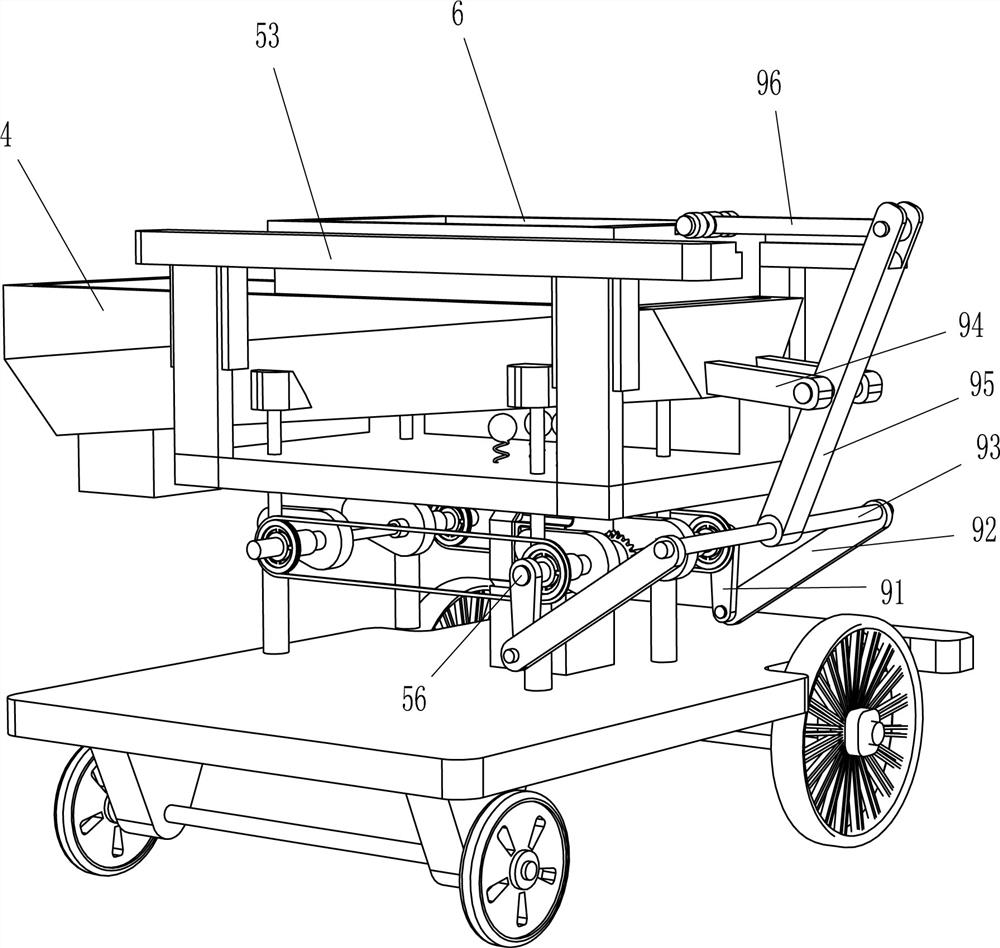

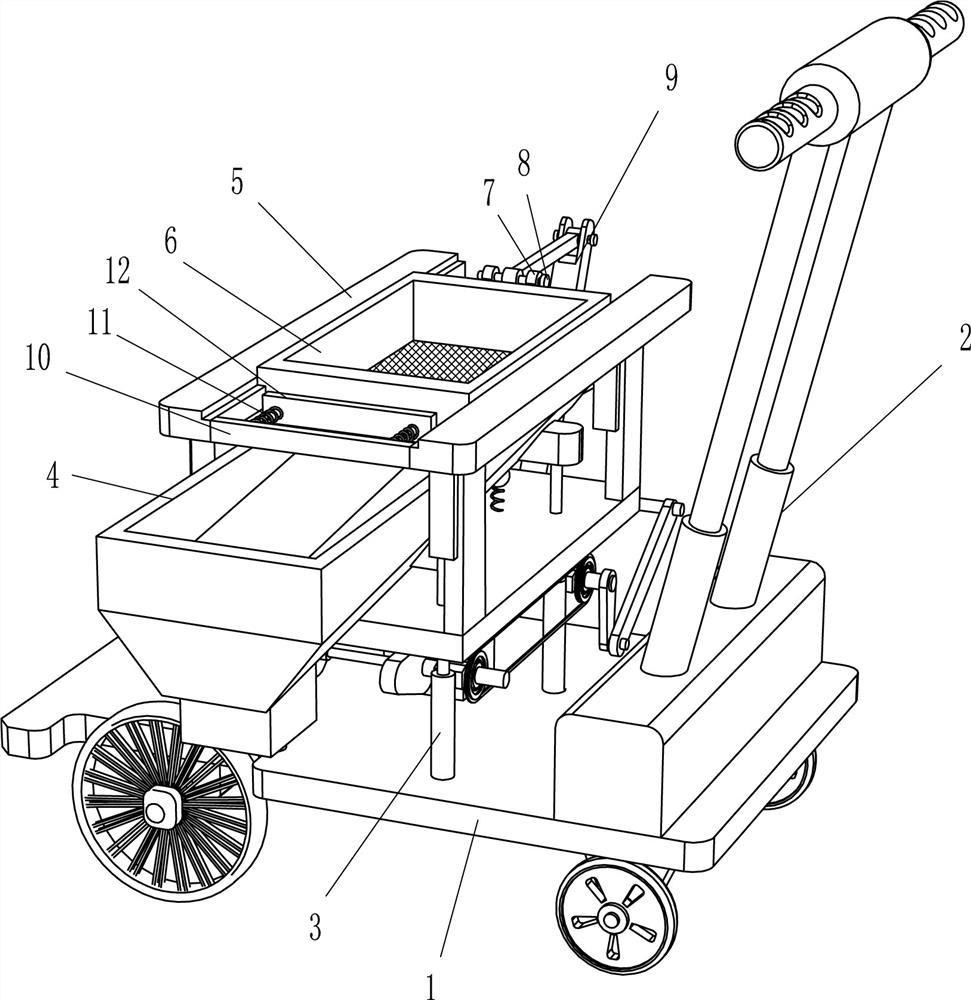

[0020] A building sand sieve, such as Figure 1-3 As shown, it includes vehicle frame 1, push rod 2, guide column 3, drop hopper 4, up and down vibration mechanism 5, screening frame 6, inserting sleeve 7, inserting rod 8 and swing mechanism 9, and the right side of the top of vehicle frame 1 is provided with The push rod 2 and the top of the vehicle frame 1 are provided with 4 guide columns 3 connected by bolts, and the 4 guide columns 3 are combined into a rectangular arrangement. The upper and lower vibrating mechanisms 5 are provided, and the upper and lower vibrating mechanisms 5 are slidingly provided with a screening frame 6. The screening frame 6 is located directly above the falling hopper 4. The left and right side walls of the screening frame 6 are symmetrically arranged with a plug sleeve 7 by welding, and the plug sleeve The plug-in type in 7 is provided with inserting rod 8, and up and down vibrating mechanism 5 is provided with the swing mechanism 9 that screen ...

Embodiment 2

[0025] On the basis of Example 1, such as Figure 1-2 As shown, it also includes a baffle plate 10, a first elastic member 11 and a buffer plate 12, a baffle plate 10 is connected between the front ends of the two slide rails 53, the rear side of the baffle plate 10 is uniformly provided with a first elastic member 11, the first elastic The member 11 is a compression spring, and the rear end of the first elastic member 11 is provided with a buffer plate 12 . The swing rod 95 drives the screening frame 6 to move back and forth on the slide rail 53 through the second connecting rod 96, and then realizes the back and forth movement of the screening frame 6. The screening frame 6 squeezes the buffer plate 12, which can play the vibration of the screening frame 6 and prevent The screen frame at the bottom of the screening frame 6 is blocked, and the first elastic member 11 plays a buffering role on the buffer plate 12 .

[0026] It also includes a second elastic piece 13 and a kno...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com