Target magnetron sputtering device and film coating method used for powder particle surface film coating

A technology for target magnetron sputtering and particle surface, applied in the field of powder particle surface coating technology, can solve the problems of inability to achieve co-sputtering, fixed coating thickness, difficult adjustment, etc., to improve efficiency, low operating cost, The effect of processing a large amount of powder

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] Embodiment 1 is used for the target magnetron sputtering device of coating on the surface of powder particles

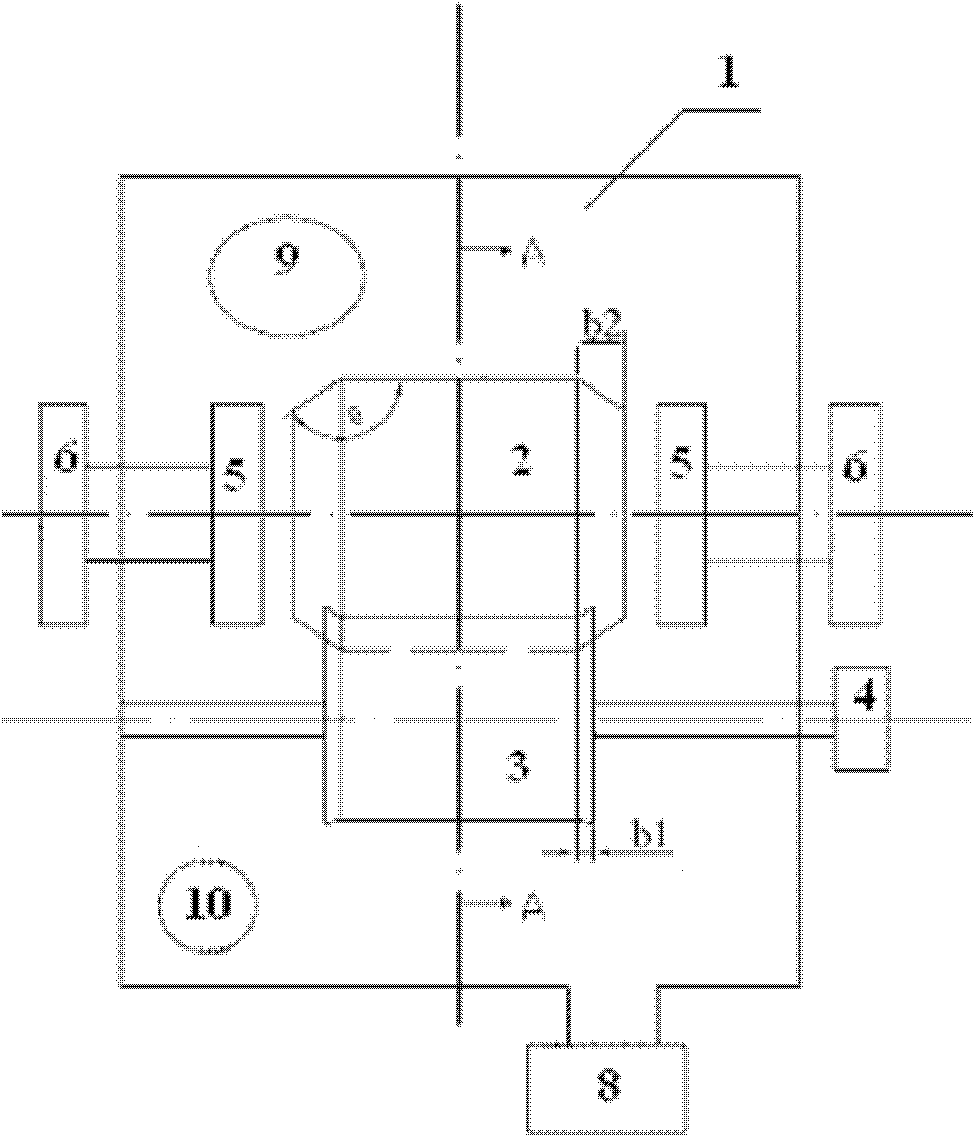

[0035] see figure 1 and figure 2 As shown, in a preferred embodiment of the present invention, the magnetron sputtering coating device includes a vacuum chamber 1, a roller 2 with openings at both ends, two support rollers 3 with limiting slopes, a motor and a speed regulating device 4 , two magnetron sputtering target frames 5 and a sputtering power supply 6 .

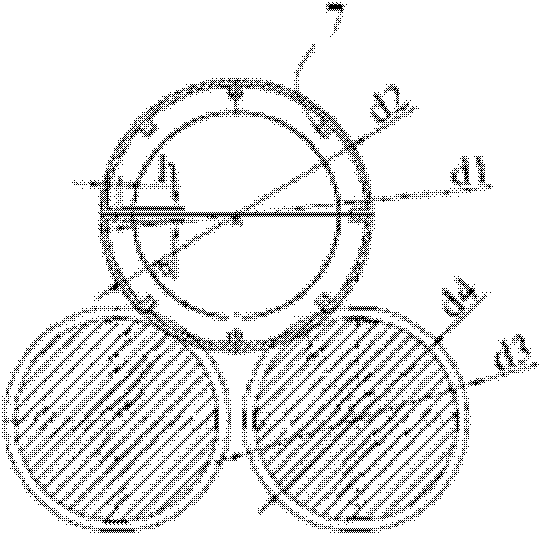

[0036] Wherein, the support rollers 3 are connected with the motor and the speed regulating device 4, and the two support rollers 3 are axially horizontal, parallel to each other and located at the same level. The axial length of the support roller 3 is 20cm, and the outer diameter d of the support roller 3 is 8cm, the inclination angle θ of the limiting slope of the support roller is 145°, and the width of the limiting slope of the supporting roller is b 1 It is 2cm.

[0037] The wall thickness...

Embodiment 2

[0040] Embodiment 2 Using the device described in Embodiment 1 to carry out magnetron sputtering copper alloy film on the surface of solid glass sphere powder particles

[0041] The process steps are as follows:

[0042] 1. Open the vacuum chamber, put 150 grams of solid glass ball powder particles with a particle size of 50 μm and 150 grams of glass grinding balls into the roller, place the roller on the supporting roller, and the diameter of the glass grinding balls is 4mm; put the required two copper The targets are respectively installed on the target frame, and the axis of the target is aligned with the axis of the roller;

[0043] 2. Close the vacuum chamber, open the vacuum pumping device, and pump the vacuum chamber to 0.5×10 -3 Pa;

[0044] 3. Fill the vacuum chamber with argon gas, and use a mass flow meter to control the flow rate to ensure that the working pressure of the vacuum chamber is 0.5Pa during sputtering;

[0045] 4. Turn on the motor, adjust the speed ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com