Classification treatment device for construction waste

A treatment device and technology for construction waste, which is applied in the direction of solid separation, separation of solids from solids with airflow, and filtration and screening, can solve the problems of large manpower assistance, low efficiency of construction waste, inconvenient collection, etc., and achieve complete separation, Ease of collection and prevent clogging

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

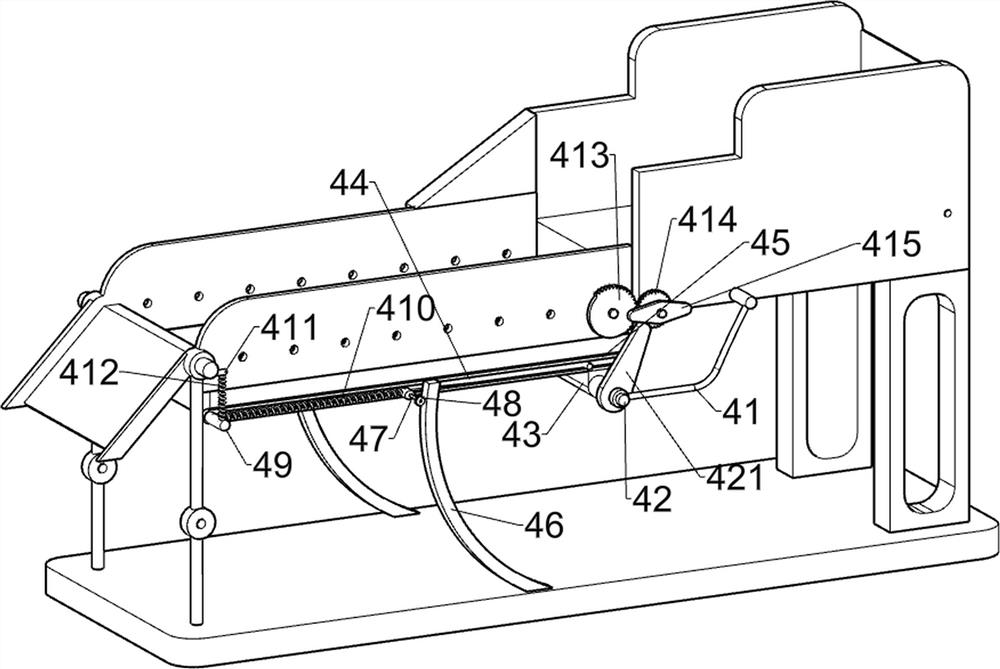

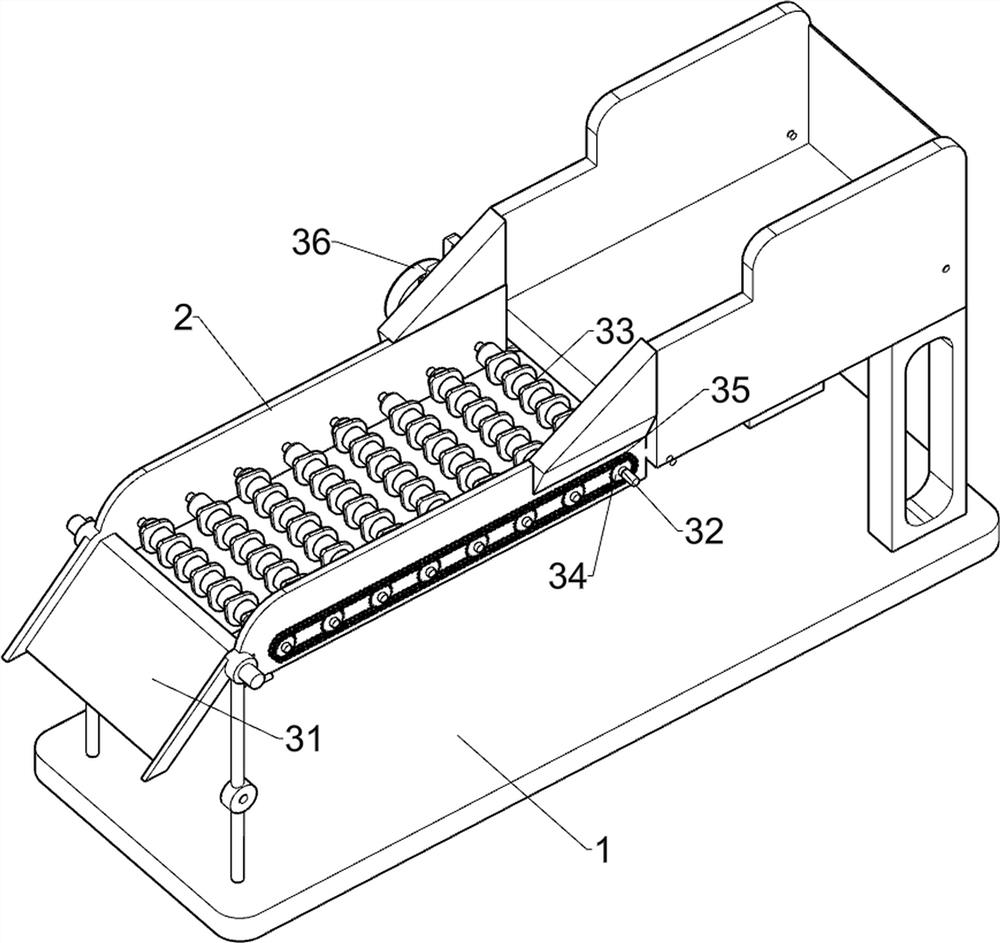

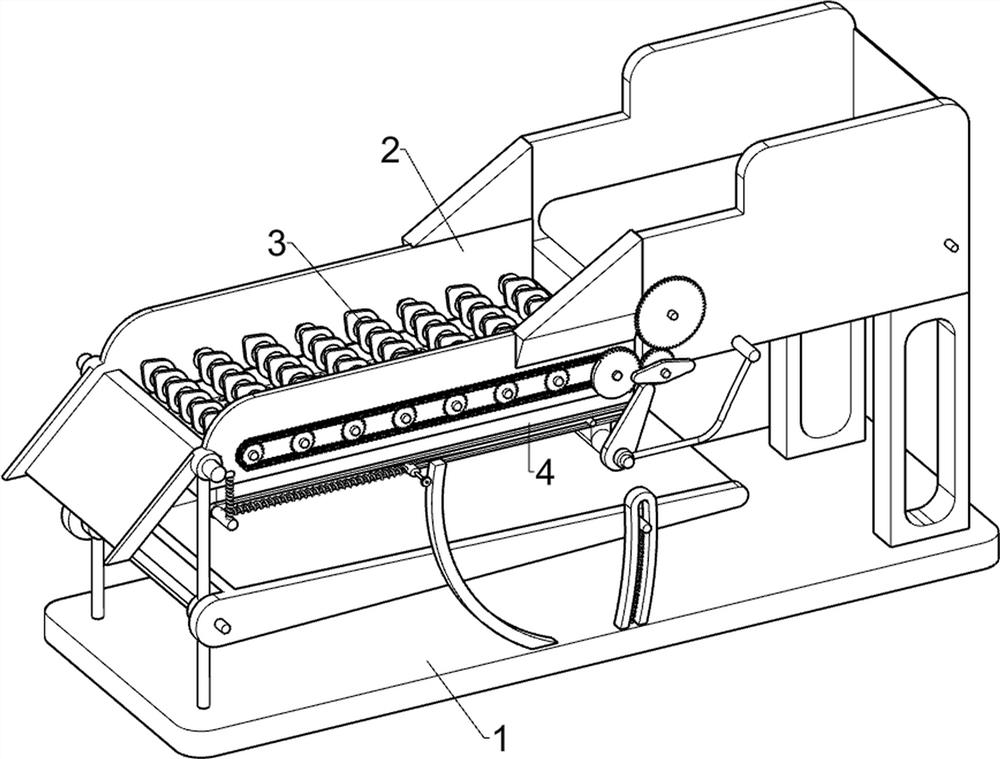

[0022] A sorting device for construction waste, such as figure 1 , figure 2 and image 3 As shown, it includes a bottom plate 1, a frame 2, a separation mechanism 3 and a screening mechanism 4. The fixed connector on the top of the bottom plate 1 has a frame 2, and a separation mechanism 3 is arranged between the left part of the frame 2. The bottom plate 1 and the frame 2 There is a screening mechanism 4 in between.

[0023] When people need to use this device, first people pour the construction waste on the separation mechanism 3, then place the collection tools under the screening mechanism 4 and on the left side of the frame 2, and then start the separation mechanism 3, and the separation mechanism 3 operates Drive the larger construction waste on it to move to the left, and make the smaller construction waste fall into the screening mechanism 4. When the larger construction waste is driven to move to the leftmost side of the frame 2, the larger construction waste The ...

Embodiment 2

[0029] On the basis of Example 1, such as Figure 4 and Figure 5 Shown, also comprise second connecting rod 5, cylinder 6, second circular gear 7 and transmission belt 8, frame 2 right side is symmetrically provided with second connecting rod 5 in the mode of rotation, on the second connecting rod 5 Both are fixedly connected with a drum 6, and the front end of the second connecting rod 5 on the left side is provided with a second circular gear 7, the second circular gear 7 meshes with the first circular gear 414, and a transmission belt 8 is wound between the drums 6.

[0030] First, people pour construction waste on the conveyor belt 8, and when the first circular gear 414 rotates, the first circular gear 414 drives the second circular gear 7 to rotate counterclockwise, and the second circular gear 7 drives the second connecting rod 5 to rotate counterclockwise , the second connecting rod 5 drives the conveyor belt 8 to rotate counterclockwise through the roller 6, and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com