Method for suppressing parasitic oscillation in gain medium of grazing incidence plate strip

A parasitic oscillation, gain medium technology, applied in the field of lasers, can solve problems such as consuming crystal energy storage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

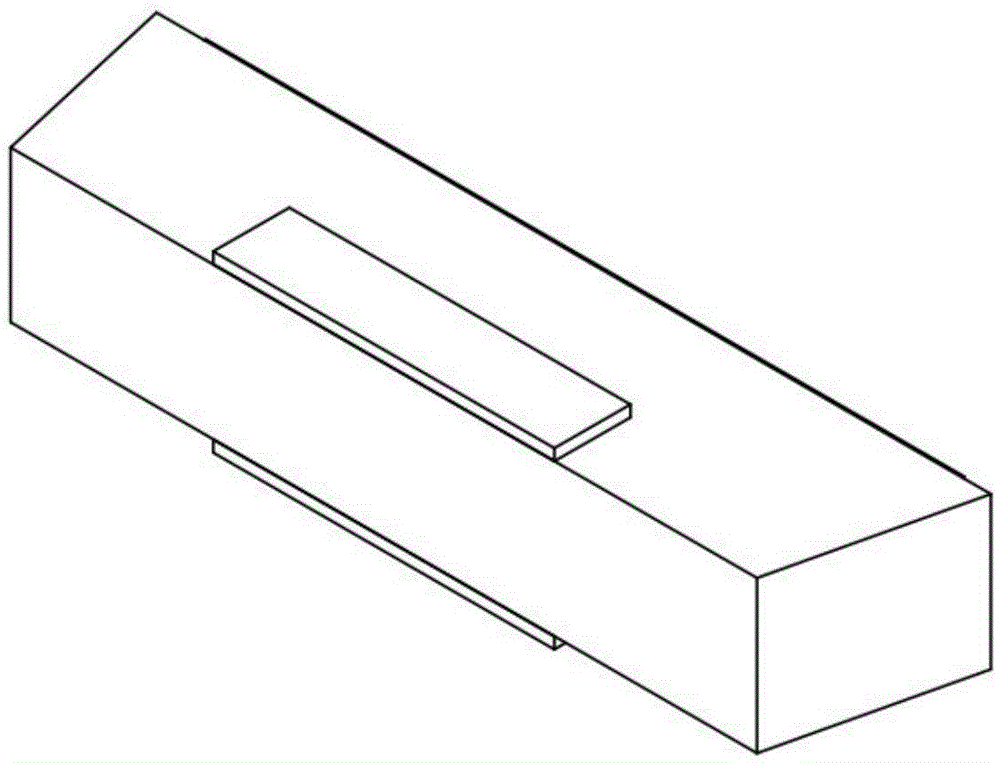

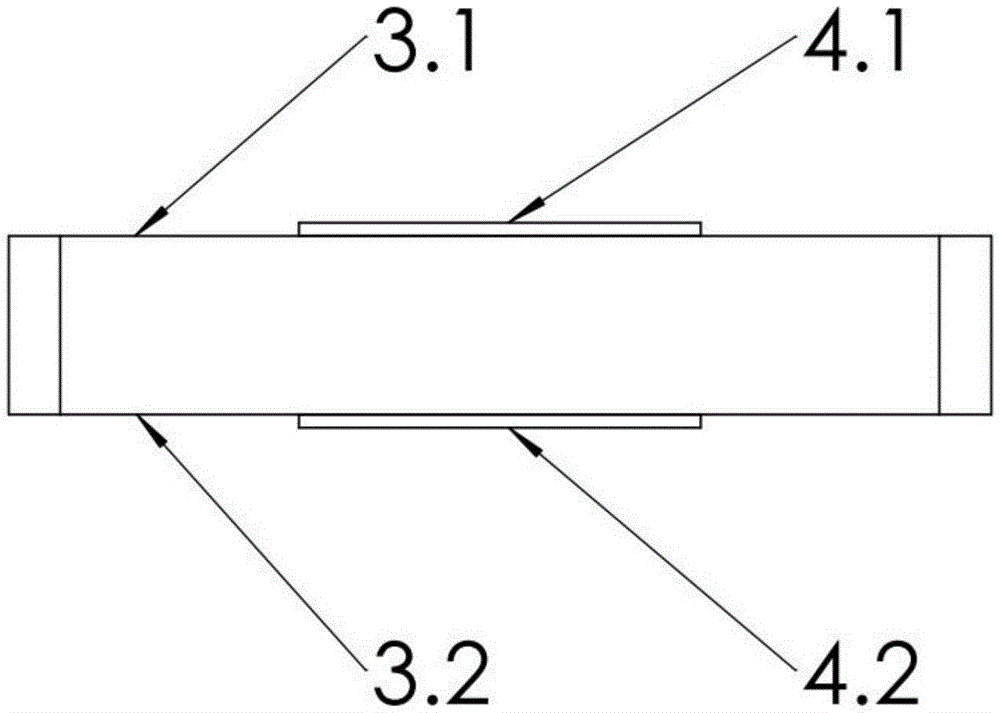

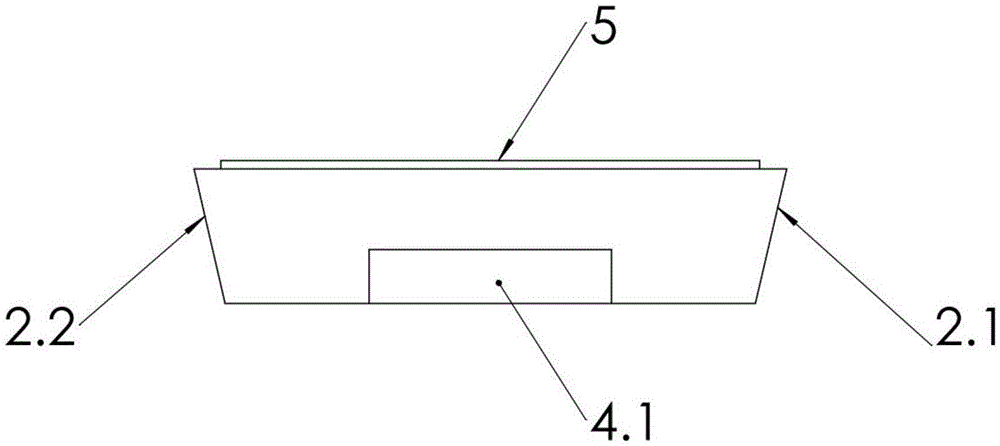

[0020] The scheme of the present invention is as follows, such as Figure 1.1-1.4 As shown, the crystal pumping surface 1.1, the non-clear surface 1.2, the crystal clear surface a2.1, the crystal clear surface b2.2, the crystal upper cooling surface 3.1, and the crystal lower cooling surface 3.2 are Nd:YAG slab crystals, respectively The six surfaces of the crystal pump surface 1.1 are coated with pump light antireflection coating; the crystal clear surface a2.1 and crystal clear surface b2.2 are the clear surfaces of the crystal. The surface is coated with oscillating light antireflection coating; the cooling surface 3.1 on the crystal and the cooling surface 3.2 on the lower crystal are the cooling surfaces of the crystal; the three non-light-transmitting surfaces are respectively the non-light-transmitting surface 1.2, the upper cooling surface 3.1, and the lower cooling surface 3.2. The upper cooling surface 3.1 of the crystal and the lower cooling surface 3.2 of the cryst...

Embodiment 2

[0024] The present invention also has an improved solution such as Figure 1.5 shown. If the germanium coating absorbs too much heat in actual use, such as being directly irradiated by pump light or signal light for a long time, it will lead to the fragmentation of the germanium coating, so that the germanium coating loses the ability to absorb parasitic oscillations in the crystal, and also It will affect the heat dissipation of the crystal. Therefore, between the crystal and the upper germanium coating layer 4.1 and the lower germanium coating layer 4.2, an upper isolation layer 6.1 and a lower isolation layer 6.2 are respectively added, and the upper isolation layer 6.1 is arranged between the upper germanium coating layer 4.1 and the crystal upper cooling surface 3.1; An isolation layer 6.2 is arranged between the lower cooling surface 3.2 of the crystal and the lower germanium coating 4.2.

[0025] The upper isolation layer 6.1 and the lower isolation layer 6.2 should m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com