Shower nozzle-structured mesoporous carbon and nanometer cobalt compound and preparation method and application thereof

A technology of mesoporous carbon and nano-cobalt, applied in the field of wave absorbing materials, can solve the problems of high cost, limited application field of electromagnetic shielding, difficult movement, etc., and achieves the effects of light weight, excellent absorption characteristics, and improved absorption effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0044] S1) Dissolve 60 g of sucrose in 100 ml of 1 mol / L sulfuric acid solution, then add 150 ml of tetraethyl orthosilicate, and stir for 2 to 3 hours to obtain a clear solution.

[0045] Transfer the clear solution obtained above to a PP plastic bottle, add 3ml to 4.5ml of 4% HF, quickly put it in a drying oven at 60°C to react for 36 hours, then raise the temperature to 100°C and 160°C in sequence, and react respectively 8 hours.

[0046] The resulting material was carbonized in a tube furnace nitrogen atmosphere at a rate of 5° C. per minute to 900° C. for 3 hours.

[0047] Finally, the carbonized material was washed with 40% HF acid solution to remove the silicon skeleton, and dried in a drying oven at 60° C. for 6 hours to obtain mesoporous carbon, which was gray-black lumps. Store the mesoporous carbon in a desiccator.

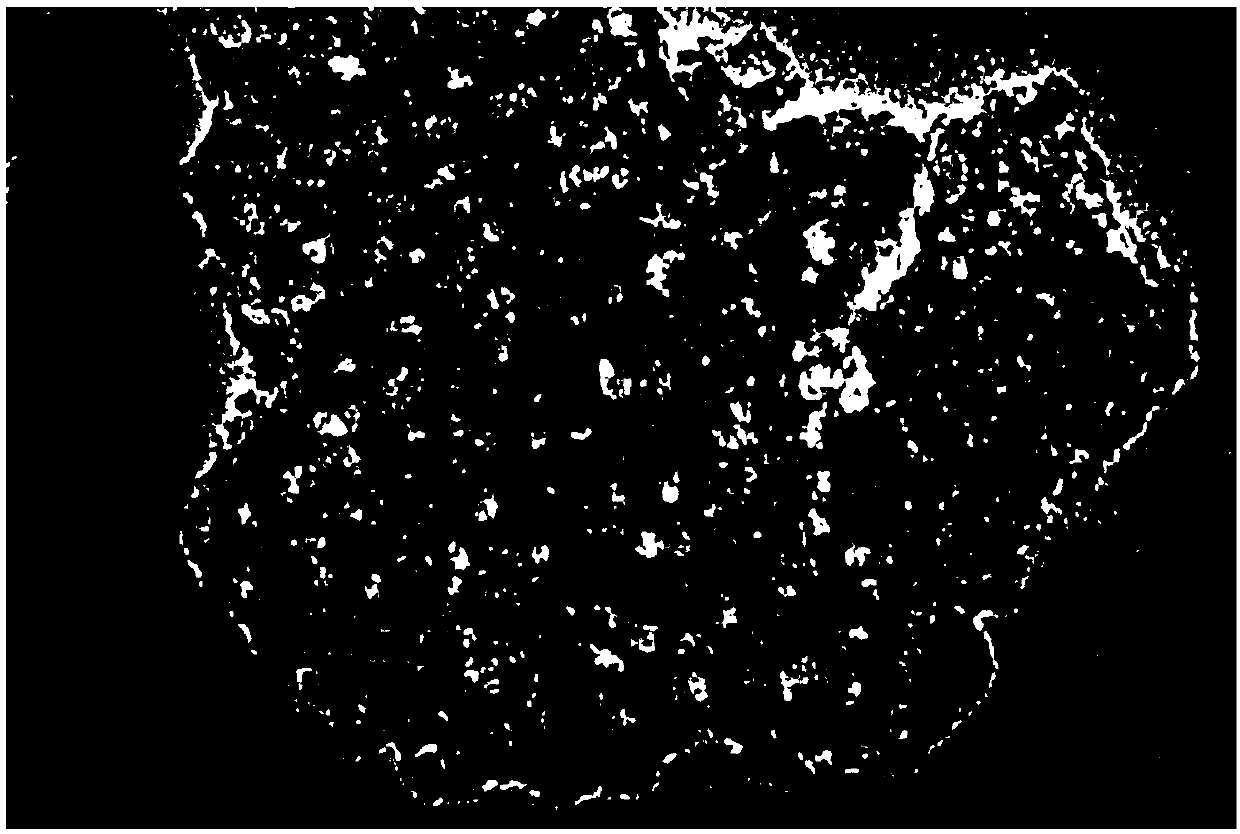

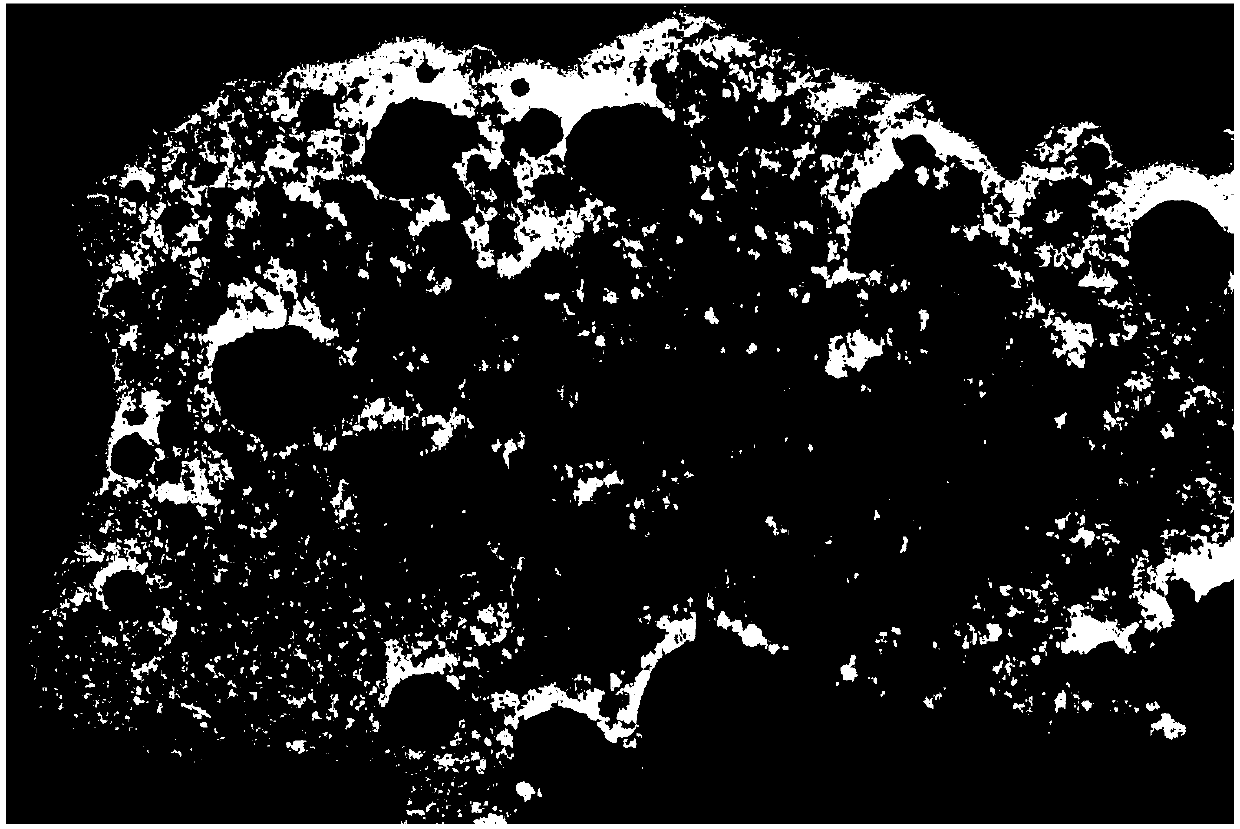

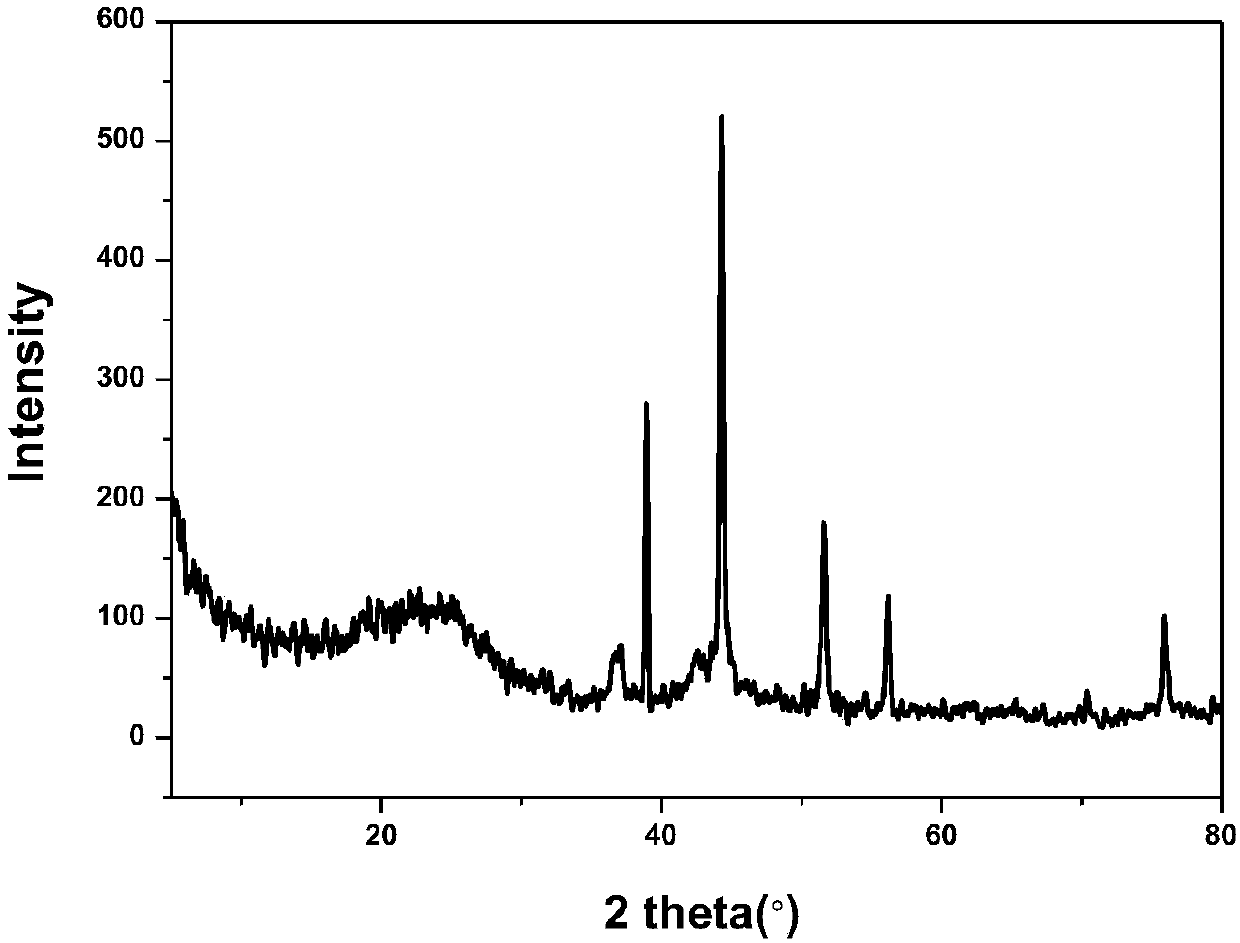

[0048] The above-mentioned mesoporous carbon is ball-milled to obtain a powder, and its transmission electron microscope picture is shown in figure ...

Embodiment 2

[0055] S1, adopt sol-gel method to prepare mesoporous carbon, its specific method is as follows:

[0056] First, 60 g of sucrose was dissolved in 100 ml of 1 mol / L sulfuric acid solution, and then 150 ml of tetraethyl orthosilicate was added, and stirred for 2 to 3 hours to obtain a clear solution.

[0057] Transfer the clear solution obtained above to a PP plastic bottle, add 3.5ml of 4% HF, quickly put it in a drying oven at 60°C for 36 hours, then raise the temperature to 100°C and 160°C in sequence, and react for 8 hours respectively.

[0058] The resulting material was carbonized in a tube furnace nitrogen atmosphere at a rate of 5° C. per minute to 900° C. for 3 hours.

[0059] Finally, the carbonized material was washed with 40% HF acid solution to remove the silicon skeleton, and dried in a drying oven at 60° C. for 6 hours to obtain mesoporous carbon. Store the mesoporous carbon in a desiccator.

[0060] The prepared mesoporous carbon is a gray-black lump, and powde...

Embodiment 3

[0067] The mesoporous carbon and nano-cobalt composite wave-absorbing material with lotus structure prepared in Example 1 is applied to the absorption of electromagnetic waves in the frequency range of 2GHz to 18GHz. The specific application process is as follows:

[0068] (1) When preparing the composite of mesoporous carbon and nanomagnetic metal cobalt, the mass ratio of mesoporous carbon to cobalt nitrate salt is 1:4. Add 30 g of the prepared mesoporous carbon and nano-magnetic metal cobalt composite powder into 70 g of silicone resin and stir for 1 h until the two are evenly mixed.

[0069] (2) Add 10ml xylene solvent dropwise to the above mixture and stir evenly. (Stirring time 0.5h~2h can be implemented; xylene 5ml~20ml can be implemented)

[0070] (3) Add 10ml of curing agent dropwise to the above mixture, and coat on the coater. (Curing agent 5ml~20ml can be implemented)

[0071] (4) Dry the coating in a cool and ventilated place to obtain a sample coating.

[007...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com