Sound absorber and sound absorbing device

a technology of sound absorber and sound absorber, which is applied in the direction of sound producing device, instruments, flooring, etc., can solve the problems of insufficient sound absorber sound absorber, insufficient see-through capability, and insufficient reflection light to see the inside through, so as to achieve good sound absorber ability and reduce nois

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first embodiment

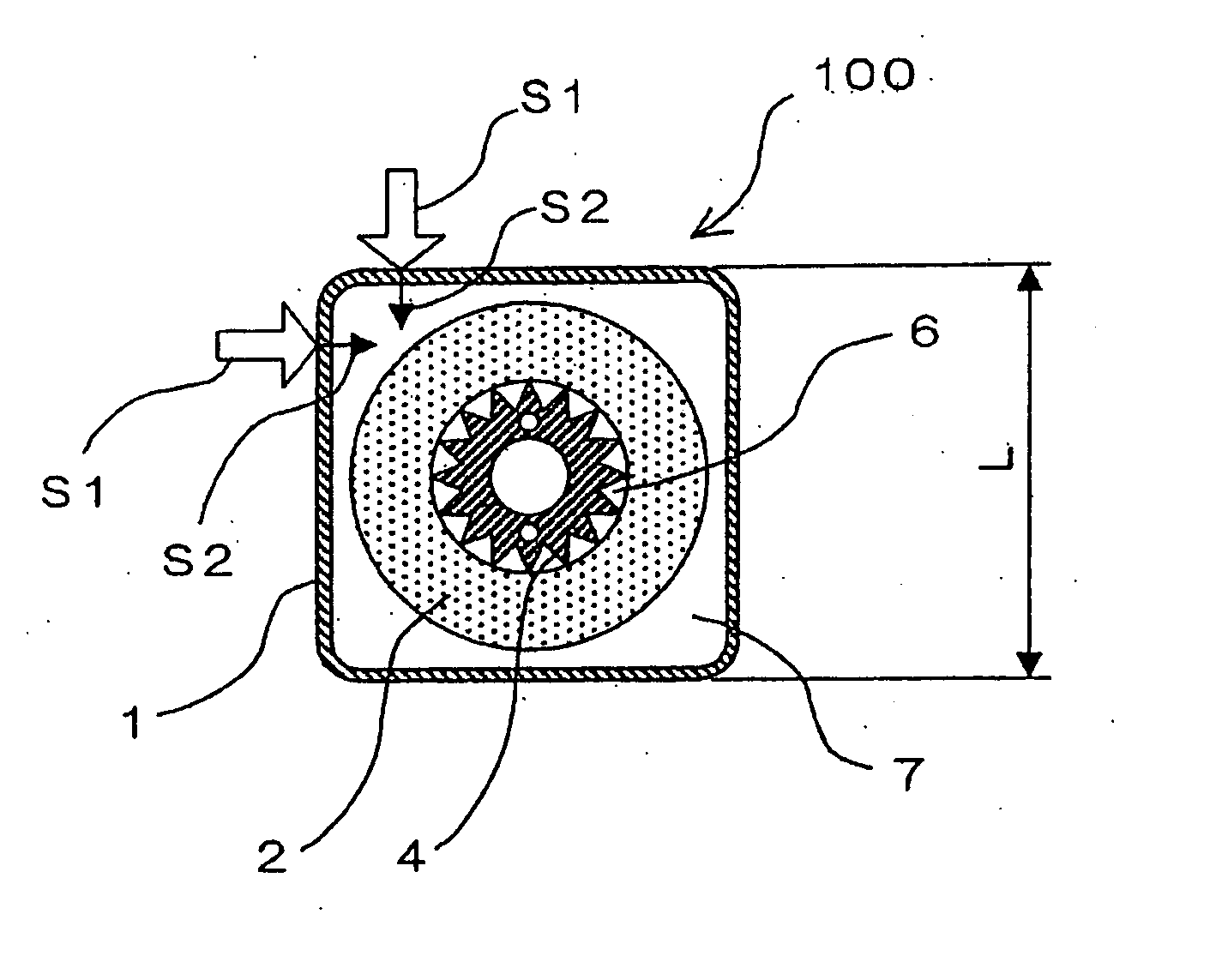

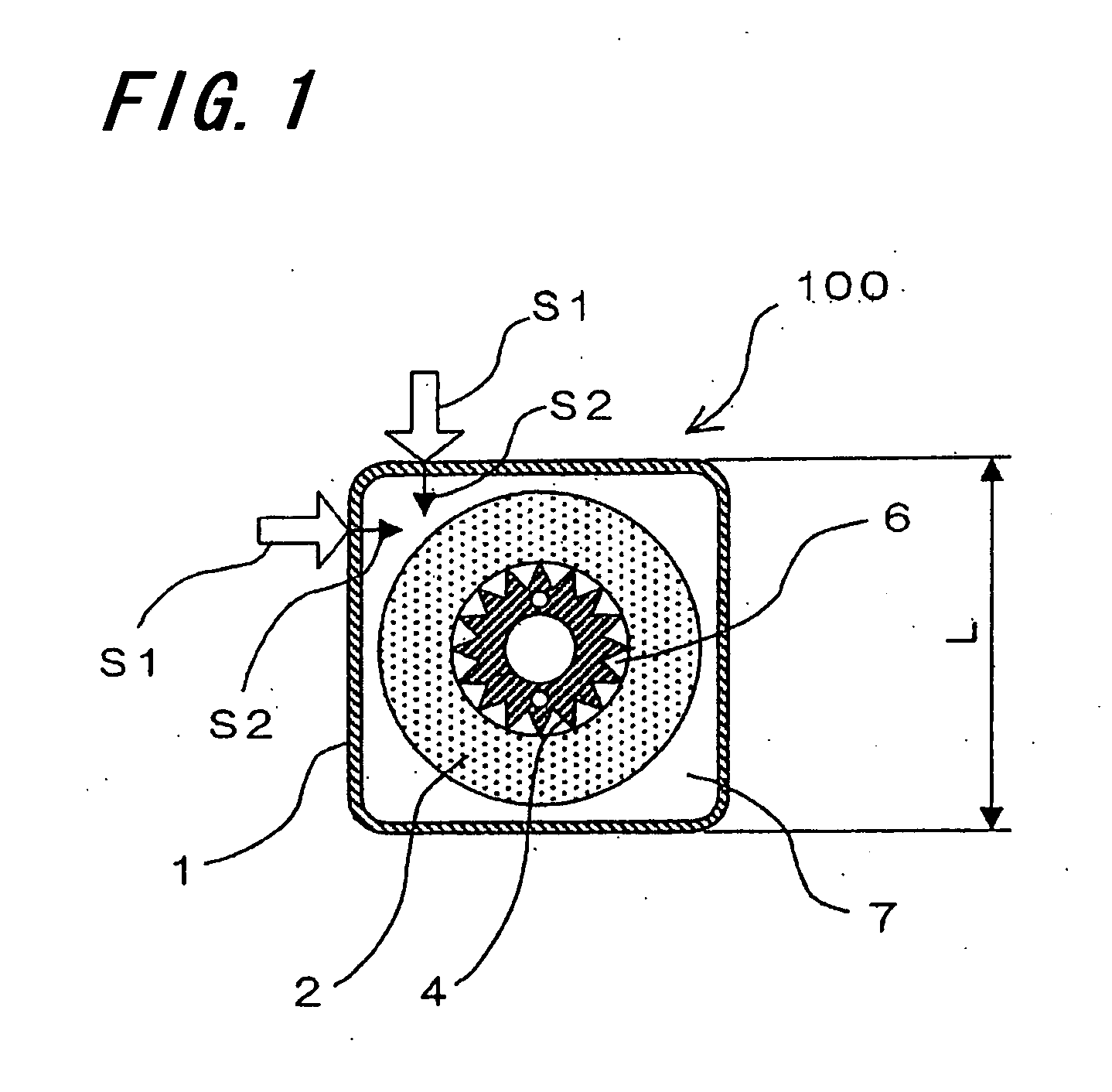

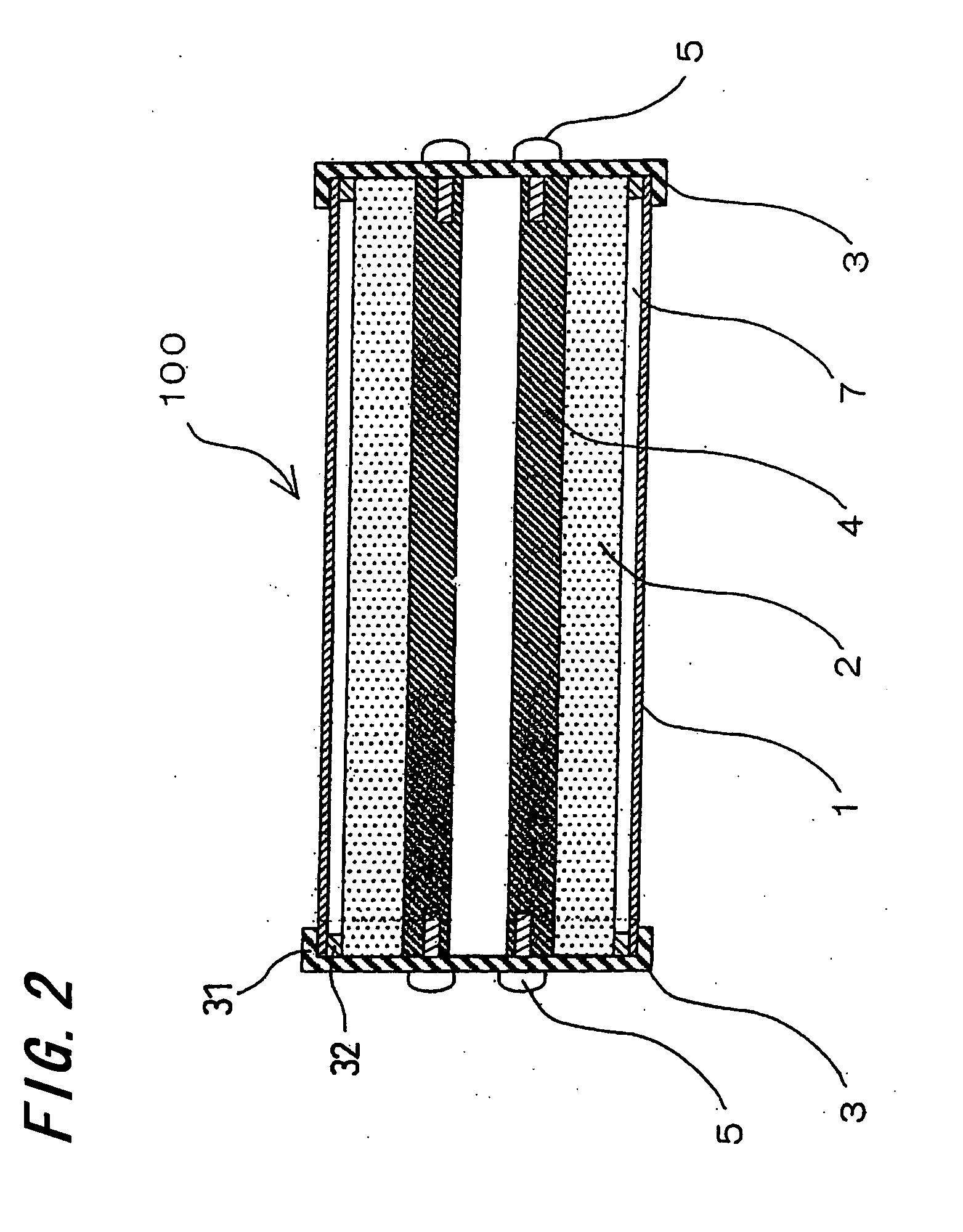

[0072]FIG. 8 is a cross-sectional view illustrating a sound absorber 101 of a first embodiment according to the fifth technical means. The sound absorber 101 has a first air layer 71 defined by a tubular porous sheath 11 having a generally rectangular cross-section with sides having sawtooth-shaped projections and depressions.

second embodiment

[0073]FIG. 9 is a cross-sectional view illustrating a sound absorber 102 of a second embodiment according to the seventh technical means. The sound absorber 101 has a first air layer 72 defined by a tubular porous sheath 12 having a generally triangular cross-section. As shown in FIG. 9, sound waves S1 emitted from unidentified directions and having reached the surfaces of the porous sheath 12 enter the first air layer 72 as sound waves S2 directed generally perpendicular to the surfaces of the porous sheath 12 and are transmitted into the air layer 72.

third embodiment

[0074]FIG. 10 is a cross-sectional view illustrating a sound absorber 103 according to the eighth technical means. The sound absorber 103 has a first air layer 73 defined by a tubular porous sheath 13 having a generally isosceles trapezoidal cross-section. The height H of the isosceles trapezoid may be generally the same as the length L of one side of the generally rectangular cross-section of the first technical means shown in FIG. 1. As shown in FIG. 10, sound waves S1 emitted from unidentified directions and having reached the surfaces of the porous sheath 13 enter the first air layer 73 as sound waves S2 directed generally perpendicular to the surfaces of the porous sheath 13 and are transmitted into the air layer 73.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com