Impedance compound right-angled muffler

A technology of impedance compounding and muffler, applied in the direction of sounding equipment, instruments, etc., can solve the problems of small wind resistance, large wind resistance, and the resistance part does not have the ability to absorb high-frequency noise, etc., to achieve the effect of strong adaptability and improved aerodynamic performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

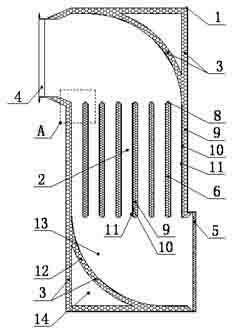

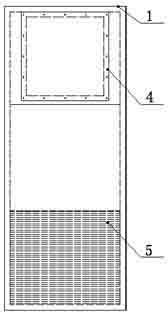

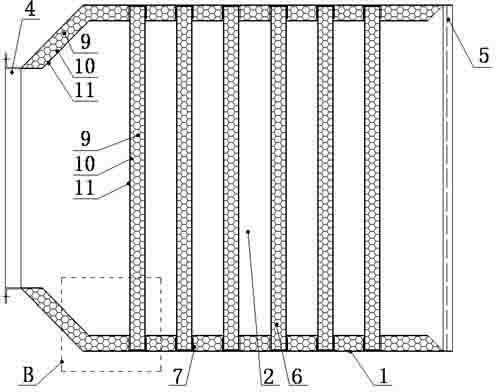

[0025] exist figure 1 , 2 , 3, 4, and 5 shown in the first embodiment, the muffler shell (1), the resistive noise reduction structure (2), the right-angle resistance noise reduction structure (3), the flange interface (4), the air outlet An impedance composite right-angle muffler composed of hundreds of sheets (5). The sheet-type sound-absorbing body (6) of the resistive noise-absorbing structure (2) is installed in the muffler shell (1) using a positioner (7), and is arranged in parallel along the airflow direction. The sheet-type sound-absorbing body is composed of (6) inner sound-absorbing material (9) covered with glass cloth (10) on both sides and the perforated face plate (11), and the face-protecting perforated plates (11) into an arc shape (8). The two sides of the resistive noise-absorbing structure (2) are right-angled resistant noise-absorbing structures (3), and the right-angled resistant noise-absorbing structures (3) are composed of cubes (13) with arc-sha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com