Automatic welding machine of aluminum-nickel compound piece of lithium ion battery cover plate

A technology for automatic welding machines and lithium-ion batteries, applied in welding equipment, metal processing equipment, manufacturing tools, etc., can solve problems affecting the quality of lithium-ion batteries, open circuits of finished batteries, high error rates, etc., and achieve quality assurance and manufacturing costs. The effect of reducing and liberating manpower

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

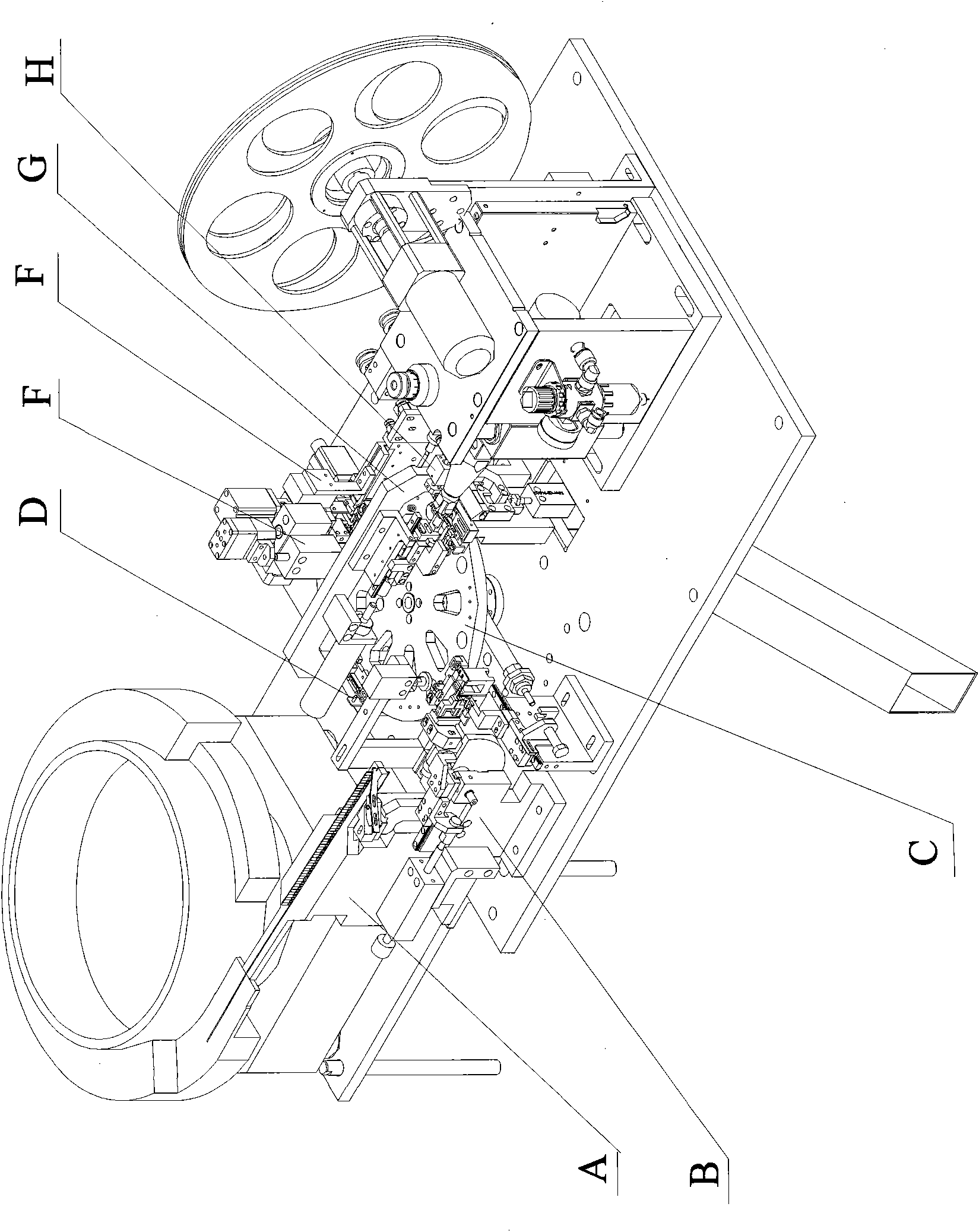

[0033] A kind of automatic welding machine for aluminum-nickel composite sheet of lithium-ion battery cover plate, such as figure 1 As shown, it consists of a feeding mechanism A, a feeding turning mechanism B, a turntable mechanism C, a detection mechanism D installed on the table of the automatic welding machine, a nickel sheet feeding mechanism E installed on the turntable mechanism C, a spot welding machine F, Composed of ultrasonic welding mechanism G, blanking mechanism H and automatic control mechanism;

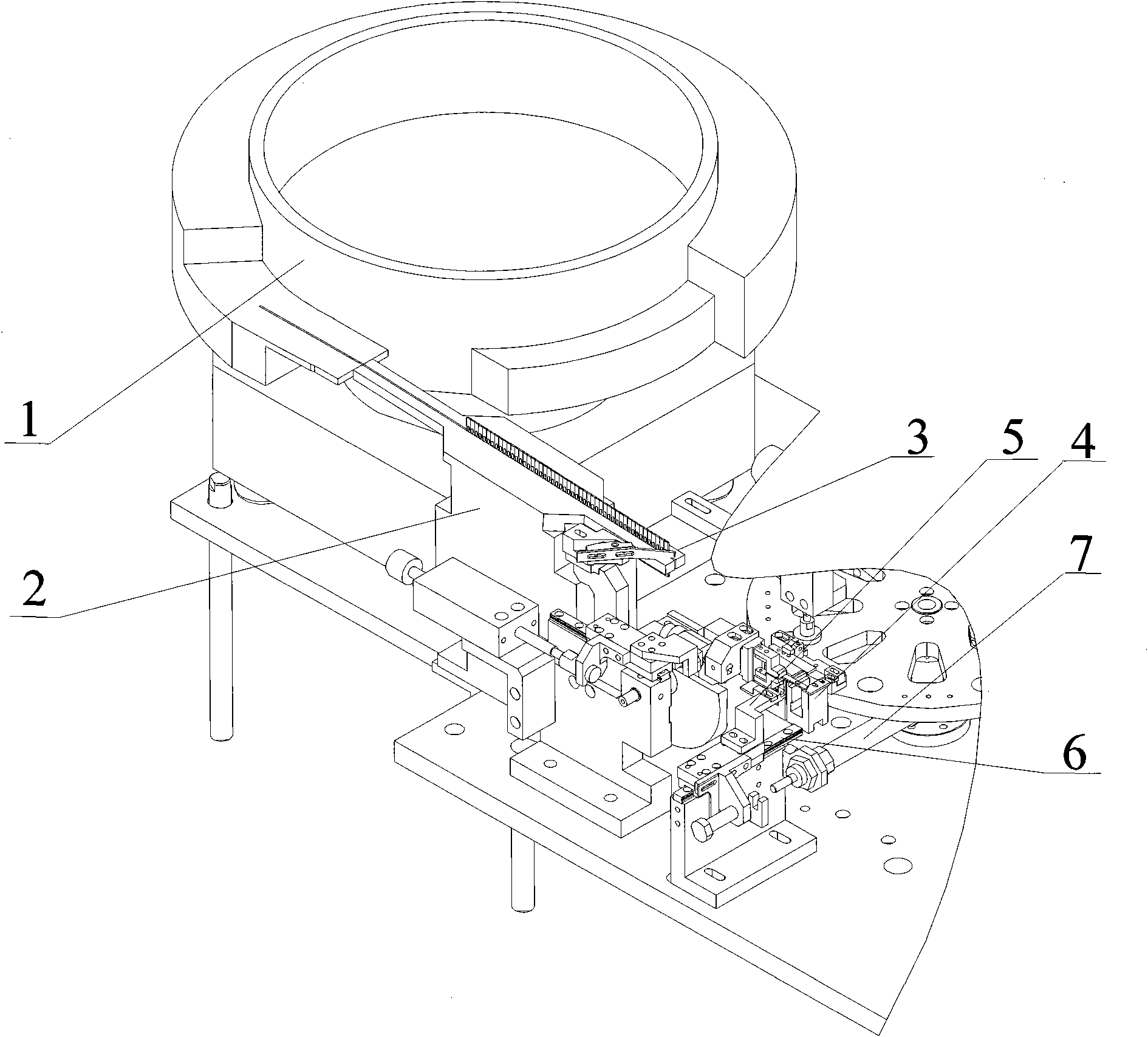

[0034] Feeding mechanism A of the present invention, such as image 3 As shown, its feeding end is a circular vibrating plate 1, connected to it is the conveying track 3 of the parallel vibrating body 2, and the transfer platform 4 provided in front of the feeding turning mechanism B, above the transfer platform 4 A push block 5 is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com