Automatic pencil feeding mechanism suitable for pencils of various specifications

A technology for pencils and pens, which can be used in office supplies, printing, sharpening devices, etc., and can solve problems such as poor versatility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

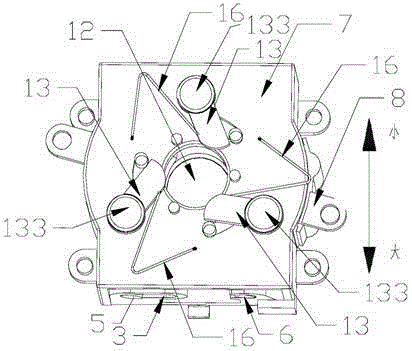

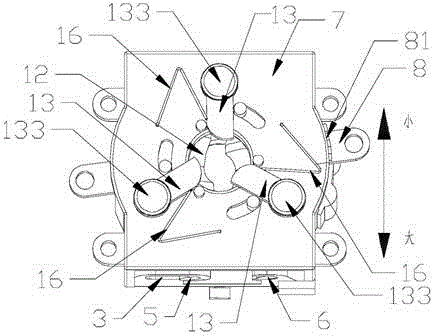

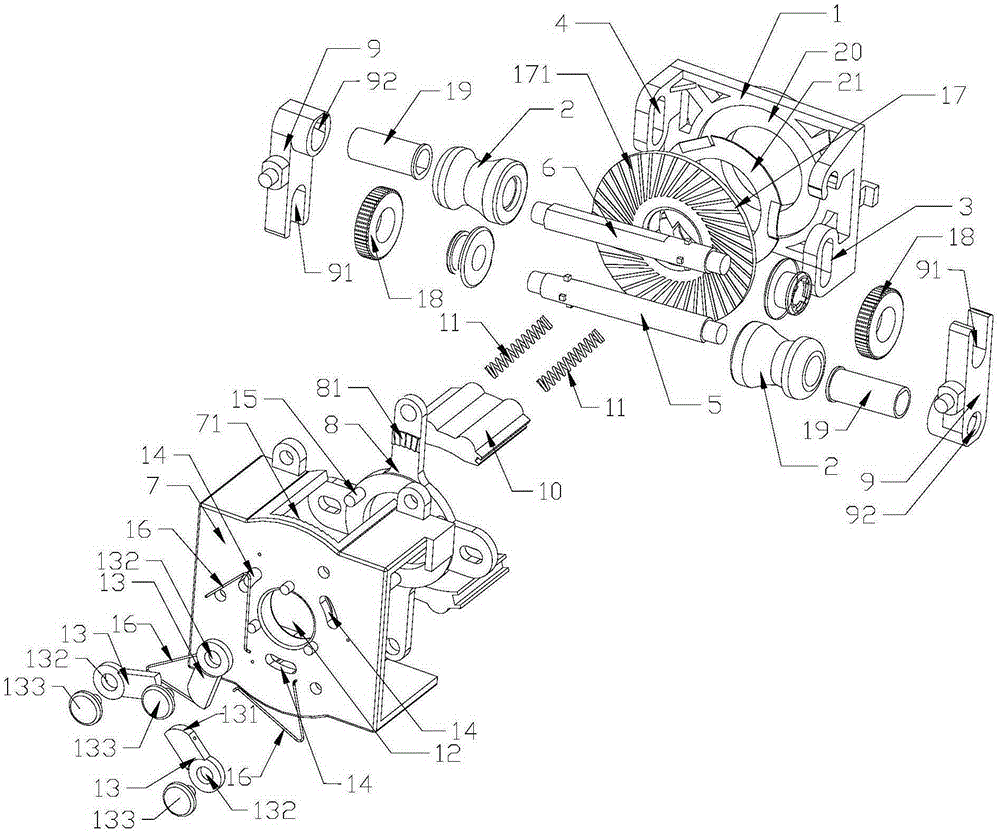

[0022] Embodiment 1: As shown in the figure, a pen feeding mechanism suitable for pencils of any specification includes a bracket 1, two installation shafts arranged in parallel and at intervals, two pen feeding wheels 2 and a mechanism for driving the two installation shafts to rotate. Drive mechanism, two pen feeding wheels 2 are sleeved on two installation shafts one by one, the outer surface of the middle part of each pen feeding wheel 2 is recessed to form a clamping surface, and the center of the bracket 1 is symmetrically provided with a first bar-shaped groove 3 and the second bar-shaped groove 4, the two installation shafts are the first installation shaft 5 and the second installation shaft 6, one end of the first installation shaft 5 is located in the first bar-shaped groove 3 and can be stressed in the first bar-shaped Move in the slot 3, the other end of the first installation shaft 5 is pivotally connected to the bracket 1, one end of the second installation shaft...

Embodiment 2

[0028] Embodiment 2: As shown in the figure, a pen feeding mechanism suitable for pencils of any specification includes a bracket 1, two installation shafts arranged in parallel and at intervals, two pen feeding wheels 2 and a mechanism for driving the two installation shafts to rotate. Drive mechanism, two pen feeding wheels 2 are sleeved on two installation shafts one by one, the outer surface of the middle part of each pen feeding wheel 2 is recessed to form a clamping surface, and the center of the bracket 1 is symmetrically provided with a first bar-shaped groove 3 and the second bar-shaped groove 4, the two installation shafts are the first installation shaft 5 and the second installation shaft 6, one end of the first installation shaft 5 is located in the first bar-shaped groove 3 and can be stressed in the first bar-shaped Move in the slot 3, the other end of the first installation shaft 5 is pivotally connected to the bracket 1, one end of the second installation shaft...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com