Front-installed vegetable and oilseed rape transplanter

A transplanter and front-mounted technology, which is applied in the direction of transplanting machinery, power devices, jet propulsion devices, etc., can solve the problems of high labor intensity, high operation intensity, missed planting, etc., and achieve the effect of improving operation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

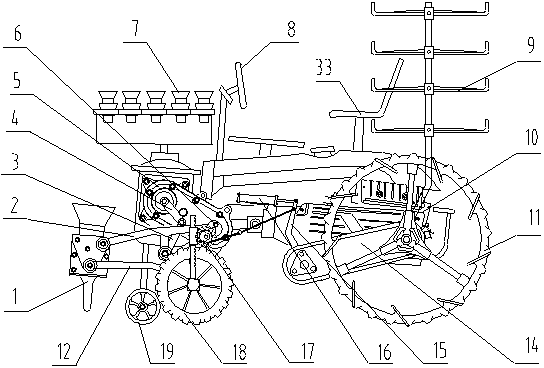

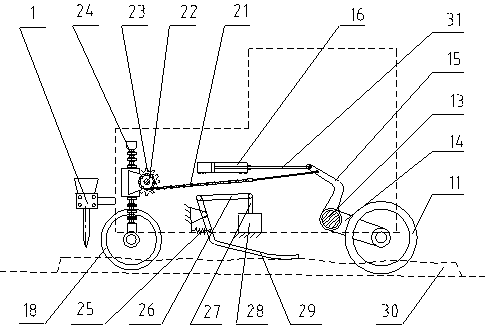

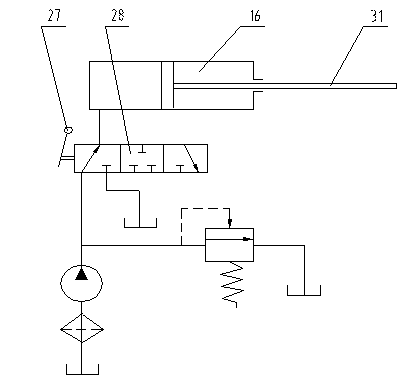

[0014] Do specific explanation below in conjunction with accompanying drawing:

[0015] exist figure 1 In the side view of the transplanting machine, the transplanting mechanism is placed at the front end of the machine, and the engine 10 is placed at the rear. The transplanting mechanism is composed of a crank 4, an intermediate connecting rod 3, a connecting rod 2, a rocking rod 12, an eccentric wheel 6, and a transplanting forceps 1 to form a complex compound kinematic mechanism. The crank 4 is connected with the output shaft of the chain case 5, and rotates with the shaft to form the crank of the four-bar mechanism. The other end of crank 4 links to each other with intermediate connecting rod 3, and the other end of intermediate connecting rod 3 links to each other with transplanting mechanism connecting rod 2, and one end of support bar 12 links to each other with chain box, and the other end links to each other with planting pincers. Wherein the connecting rod 2, the m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com