Cotton wool packing and sleeving equipment

A technology of packaging and equipment, applied in the field of textile cotton processing, can solve the problems of unrealized automatic cotton processing into cotton wool and reduce work efficiency, so as to achieve the effect of improving equipment work efficiency, increasing service life and reducing labor burden

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

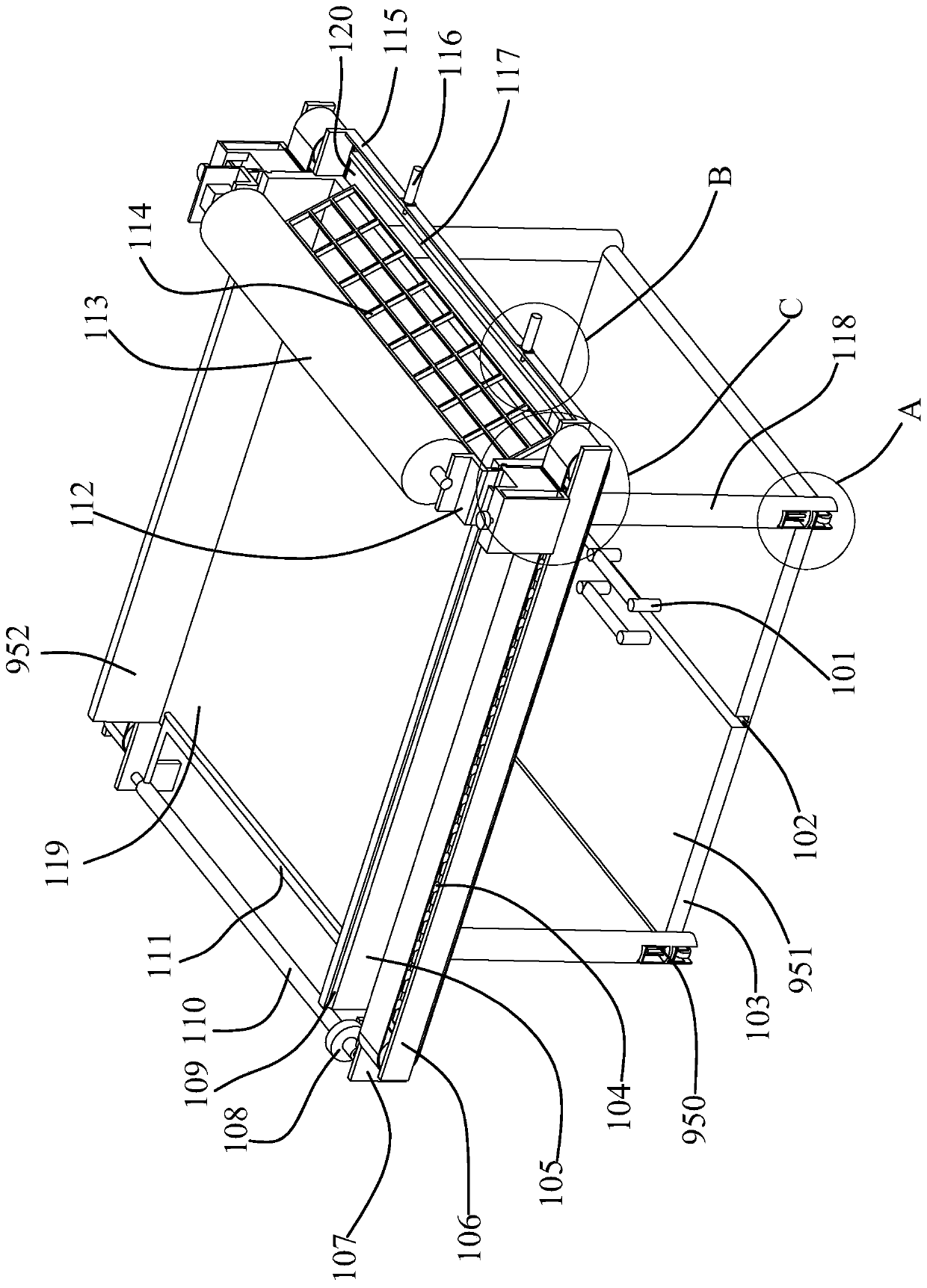

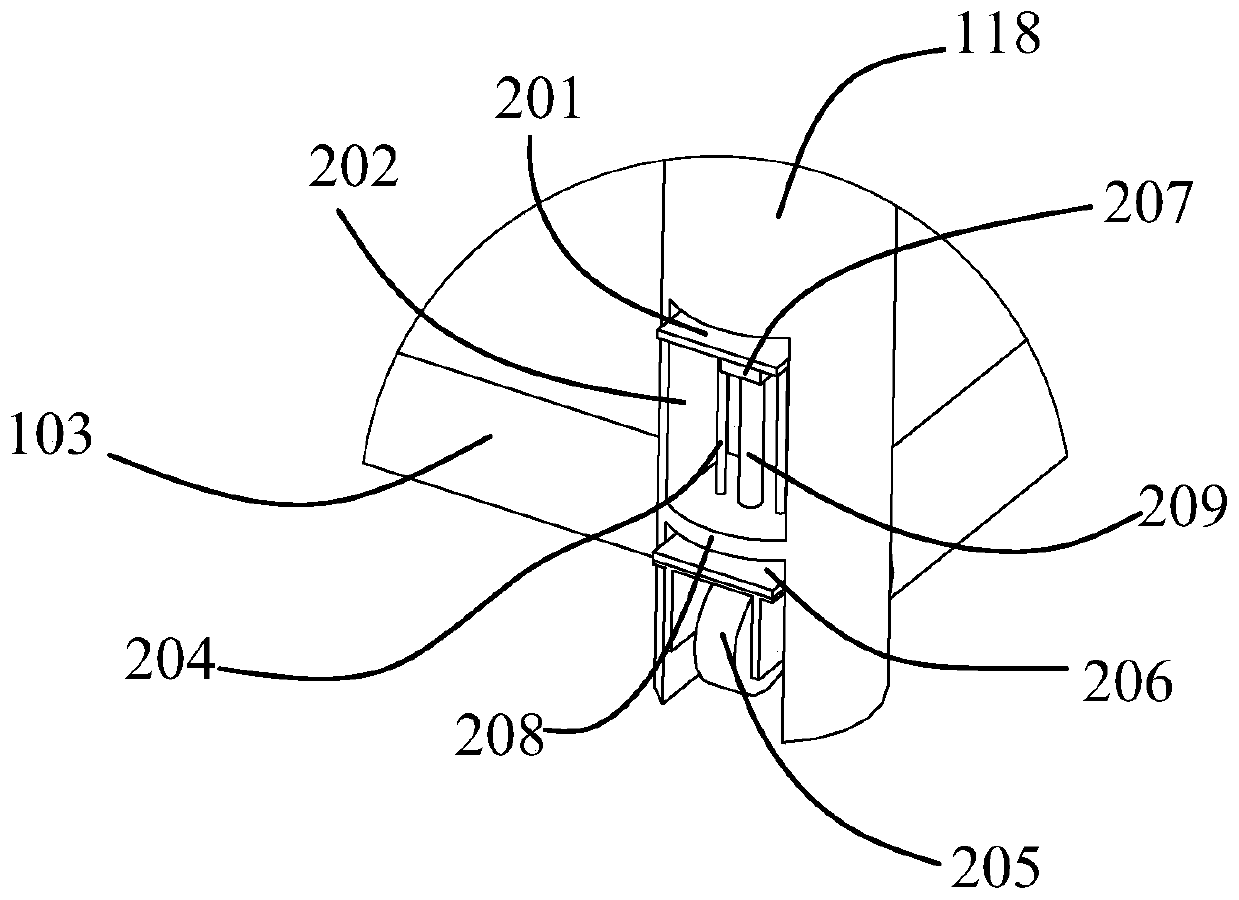

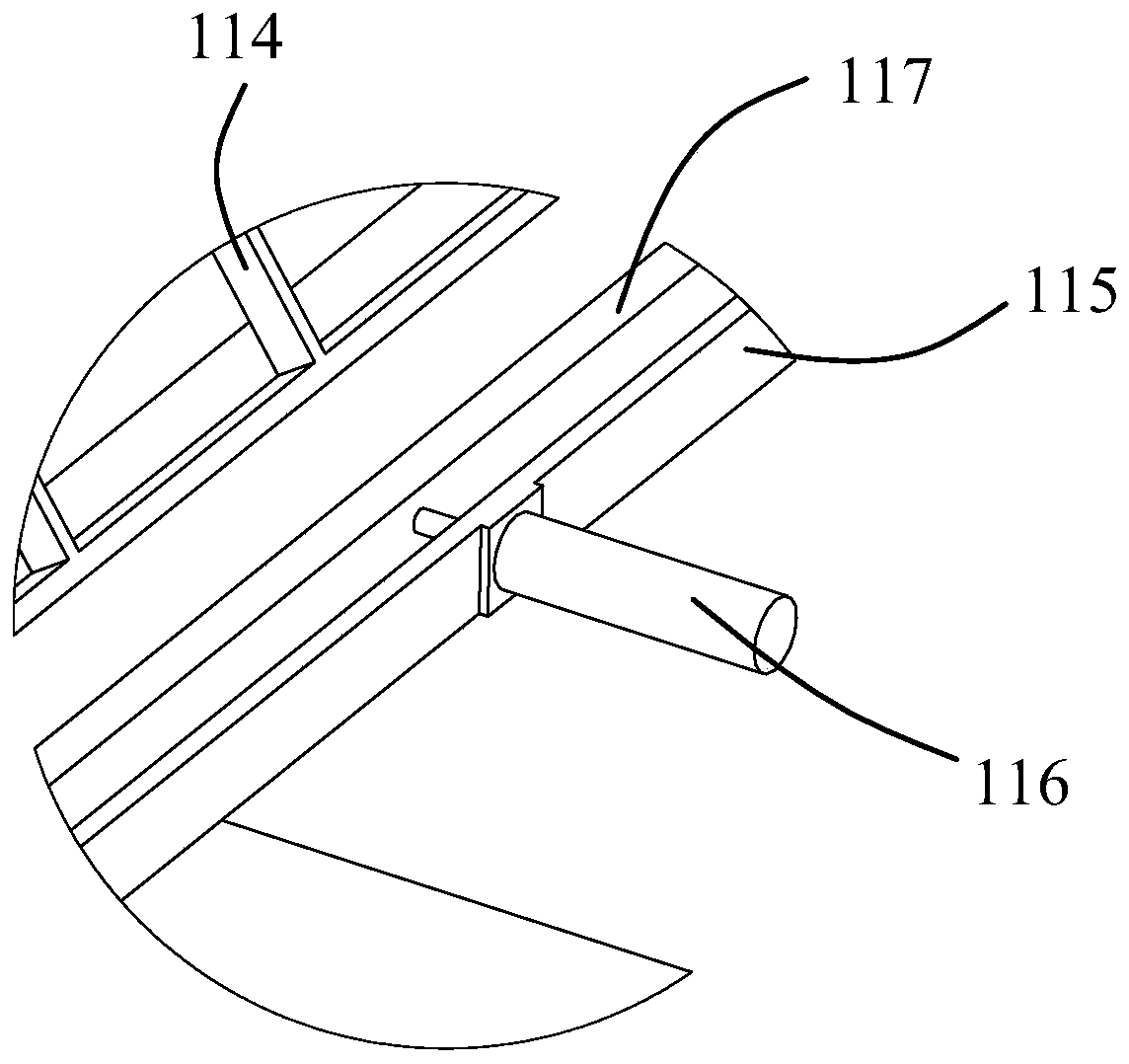

[0028] Such as Figure 1-Figure 9 As shown, the present invention is described in detail, and for the convenience of description, the orientations mentioned below are now specified as follows: the up, down, left, and right front and back directions mentioned below are consistent with the up, down, left, right, front and back directions of the projection relationship of Fig. 1 itself, a kind of cotton wool of the present invention The packaged equipment includes a platform plate 119, the upper end of the platform plate 119 is fixed with a front and rear symmetrical vertical plate 105, and the vertical plate 105 is fixed with an open circular groove 109. The diameter of the circular groove 109 is at least 1 cm, and the platform plate 119 is lower The end face is fixed with supporting feet 118 arranged in a circular array. The diameter of the supporting feet 118 is at least 8cm. The supporting feet 118 are provided with a retractable mobile device 950 to facilitate the movement of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com