Trailing arm lock with detachable and replaceable trailing arms for double-column automobile elevator

A lift and support arm technology, which is applied in the field of double-column car lift support arm locks, can solve problems such as falling off, unfixed support arms, and loose grooved frames, so as to improve use efficiency and prevent accidents , good meshing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

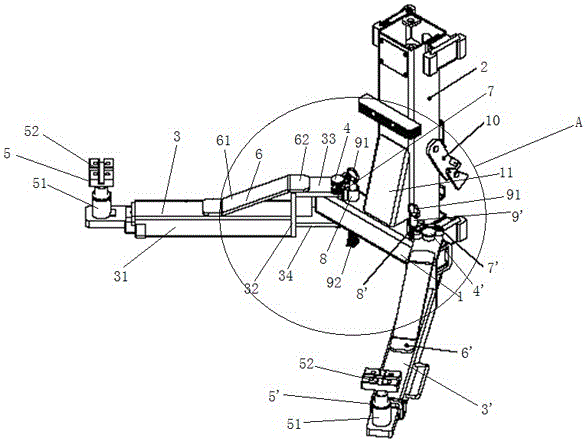

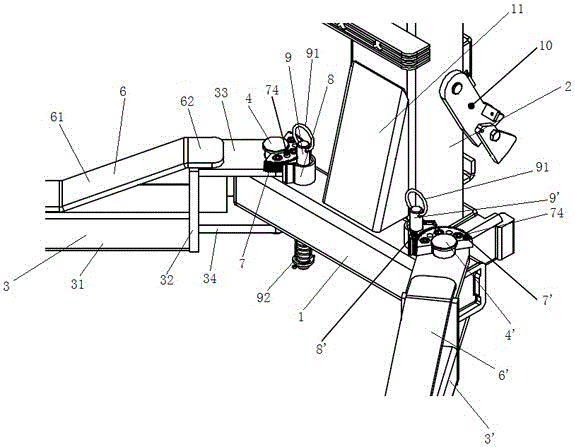

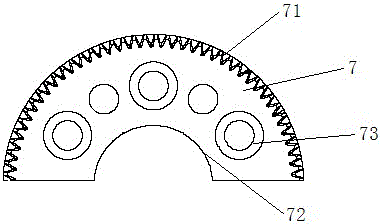

[0024] refer to Figure 1~Figure 4 , A kind of support arm lock with removable and replaceable support arms of the present invention includes: a cross beam 1, which is arranged horizontally, and two ends of its upper surface are respectively provided with a connecting through hole (not shown) symmetrically along the longitudinal direction. The two ends of the upper surface of the beam 1 located on the inner side of the two connecting through holes are also provided with a mounting through hole (not shown) symmetrically along the longitudinal direction; Connected to the middle part of a side surface of the beam 1; the two long support arms 3, 3' respectively include a straight rod 31, a straight plate 32 connected to one end face of the straight rod 31, and a first and a second symmetrically arranged on the upper and lower ends of the straight plate 32. Two connecting plates 33, 34, the first and second connecting plates 33, 34 are respectively provided with shaft holes (not sh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com