Pneumatic brake cylinder

A pneumatic brake and brake technology, applied in the direction of brakes, brake cylinders, brake components, etc., can solve the problems of high cost, expensive disassembly, difficult installation, etc., and achieve the effect of reducing installation cost and simplifying installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

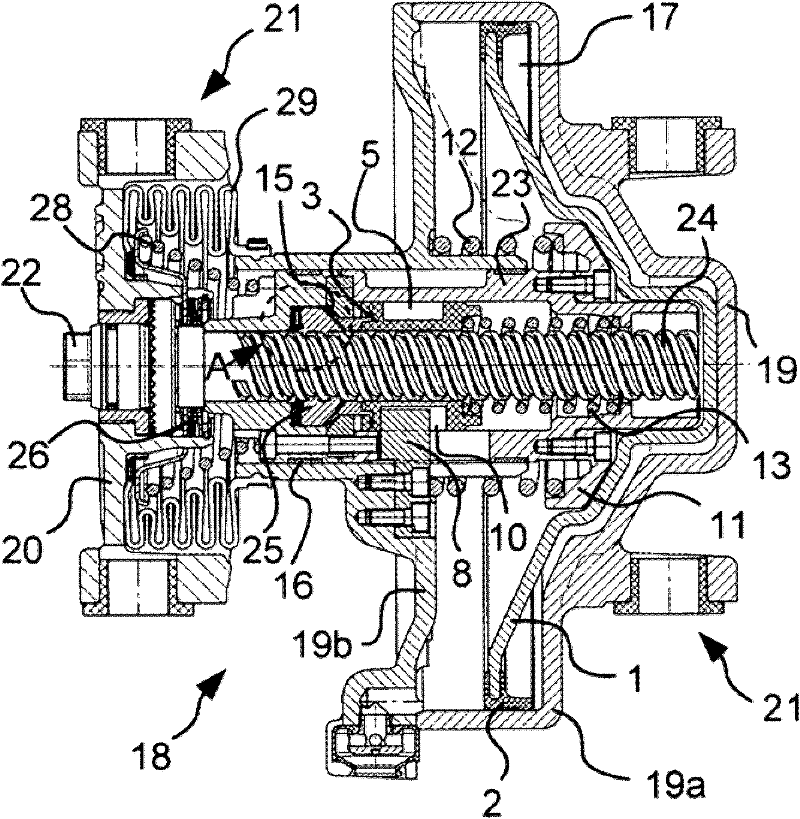

[0028] The fixing device 21 of the brake caliper is located on the one hand on the yoke 20 and on the other hand on the housing 19 assembled from the cylinder 19a and the cover 19b. In order to actuate the brake, the brake calipers (not shown here) have to be pressed apart from one another, which means that the distance between the yoke 20 and the housing 19 has to be enlarged.

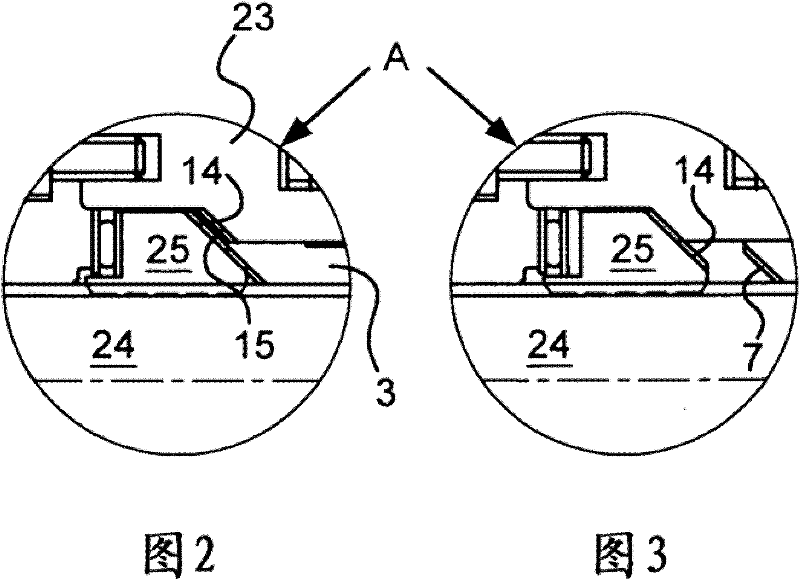

[0029] The piston 1 is arranged in the housing 19 . A pressure chamber 17 is formed by the piston 1 and the cylinder 19 a of the housing 19 . The compressed air connection via which the compressed air is supplied to the pressure chamber 17 is not visible in this illustration. Piston 1 operates piston tube 23 . However, the piston 1 is not fixedly connected to the piston tube 23 but is inserted loosely into the brake cylinder. Piston tube 23 is actuated exclusively via an annular, conically shaped contact surface, by means of which piston 1 is pressed against spring disk 11 which is screwed to pisto...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com