Setting method of steel tube and hole-opening end plate embedded part

A technology of pre-embedded parts and hole ends, which is applied in the directions of buildings and building structures, can solve the problems of difficulty in ensuring the quality of concrete at the end joints and difficulty in setting stirrups at the top of reinforced concrete columns, so as to save the difficulty of positioning and solve the problem of setting up. Difficult, stress-defined effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

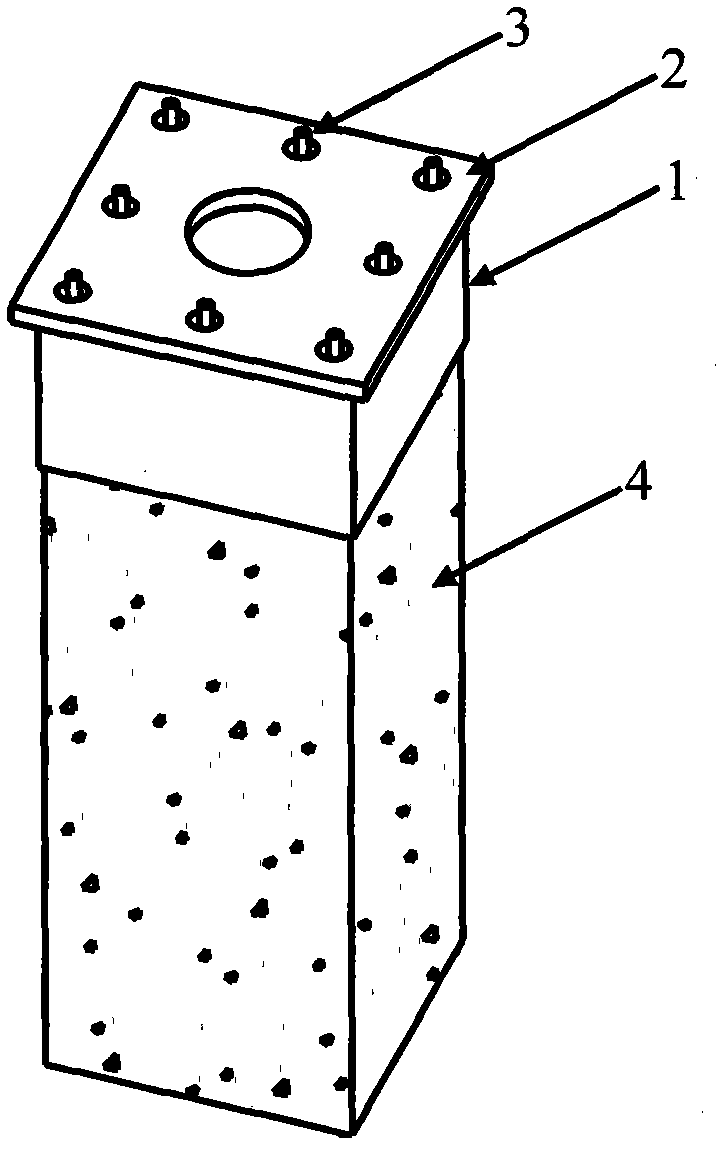

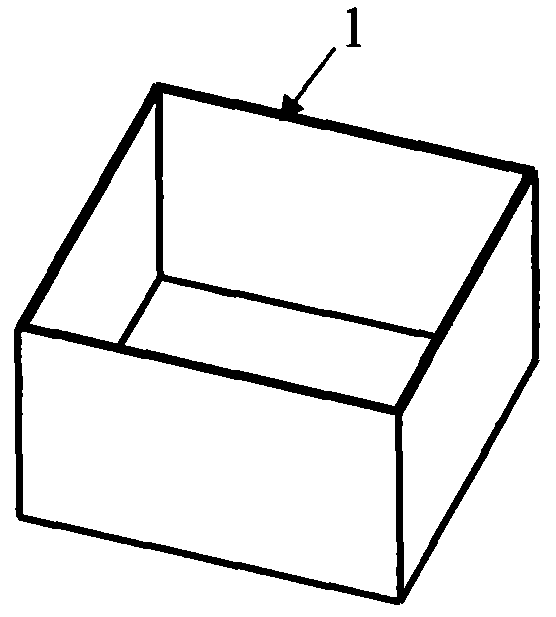

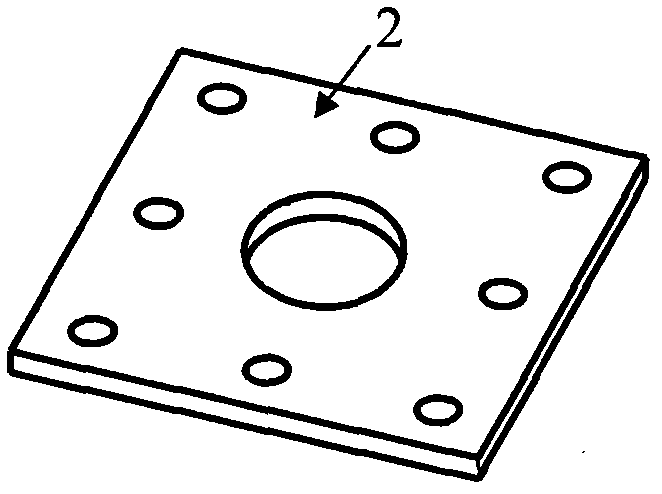

[0012] The specific embodiment of the present invention will be described with reference to the accompanying drawings. The steel pipe 1 and the perforated end plate 2 are combined to form a pre-embedded part, wherein in the corresponding position of the perforated end plate 2 and the longitudinally distributed steel bar 3, a round hole slightly larger in diameter than the longitudinal steel bar 3 is opened for the longitudinal steel bar 3 Through the hole, the concrete 4 pouring stage, the hole offered on the end plate 2 can be used as the exhaust hole when pouring the concrete 4, and a large circular hole for pouring concrete is opened at the end plate 2 center. The planar size of the perforated end plate 2 is 100-200mm larger than the cross-sectional size of the steel pipe 1. The perforated end plate 2 is welded to the steel pipe 1. The cross-sectional size of the inner wall of the steel pipe 1 is the same as the cross-sectional size of the reinforced concrete column 4. The ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com