Truss platform for high and large space top plate concrete construction

A technology of tall space and truss platform, which is applied in the direction of scaffolding supported by housing structure, housing structure support, housing structure support, etc. Safe and reliable construction, ensuring the effect of pouring quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

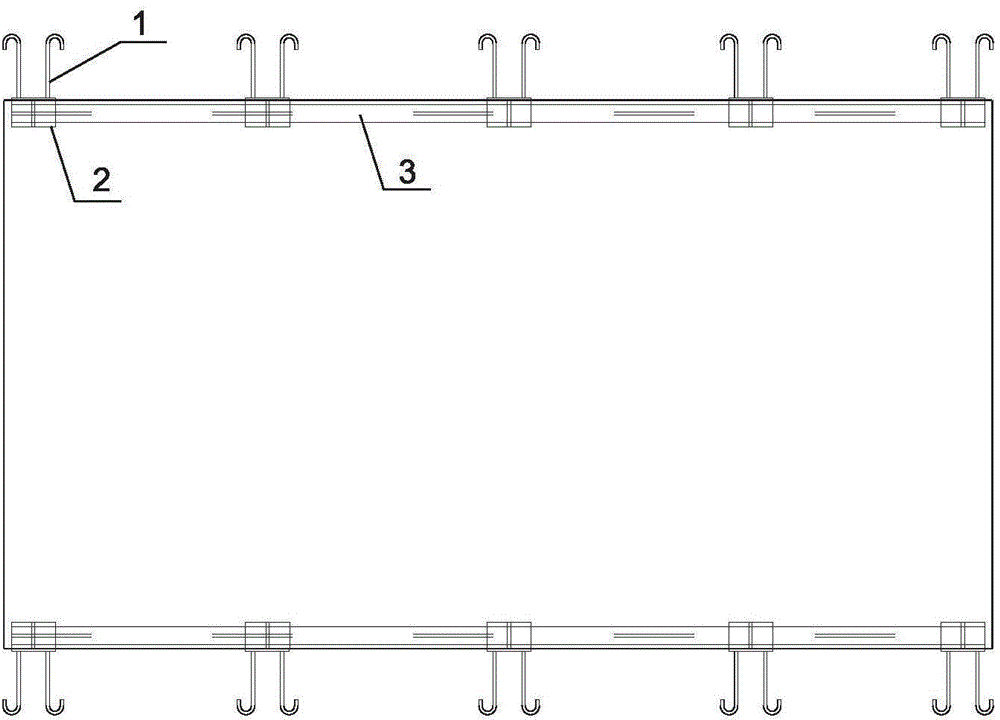

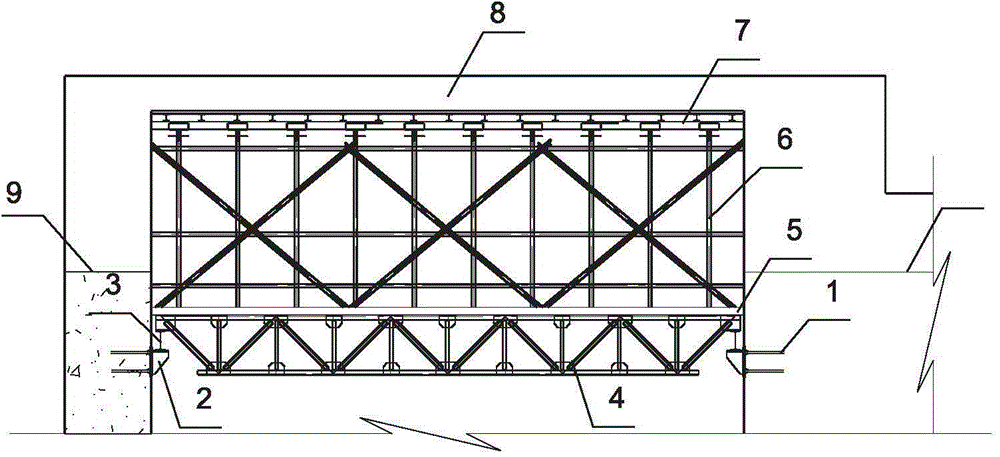

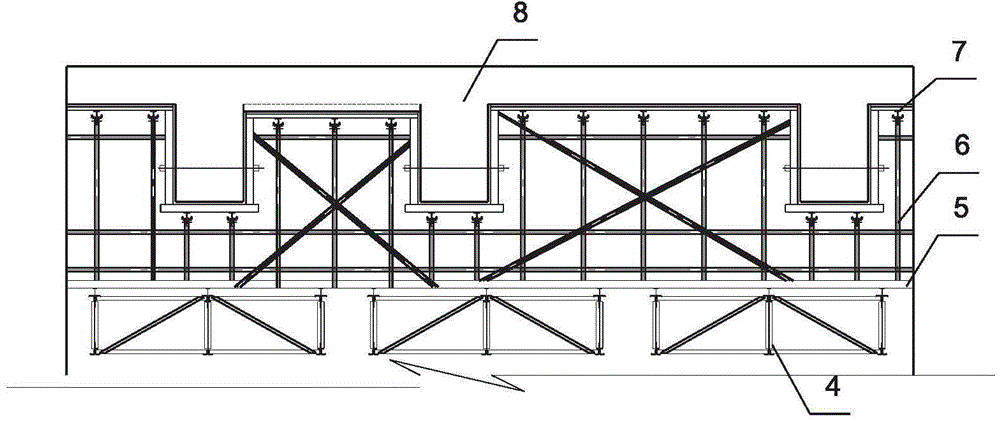

[0017] Such as Figure 1~Figure 5 As shown, a truss platform for concrete construction of a high and large space roof includes a truss support iron part 1, a steel corbel 2 is fixedly connected to the truss support iron part 1, a rail 3 is installed on the steel corbel 2, and a rail 3 is installed on the rail 3 There is a steel frame truss 4, which can slide on the track 3, and a backing plate is laid on the steel frame truss 4, on which a full hall frame 6, a supporting purlin and a formwork 7 are set up.

[0018] The iron part 1 of the truss support is composed of steel plates and anchor bars, and is pre-embedded close to the formwork surface when the lower concrete is poured.

[0019] The steel corbel 2 is welded on the iron part 1 of the truss support, and the rail 3 is welded on the steel corbel 2 .

[0020] The steel frame truss 4 is processed into a chamfered platform shape, and the steel frame truss 4 is buckled on the track 3 when installed, and is pulled and moved a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com