Green building self-heat-insulation structure system

A green building, self-insulation technology, applied in building components, building structures, insulation, etc., can solve the problems of fire insulation layer peeling, poor durability, environmental pollution, etc., to achieve increased water storage, good durability, and environmental protection Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

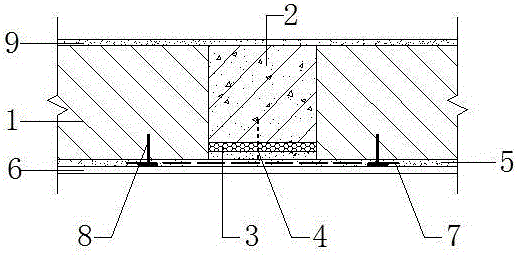

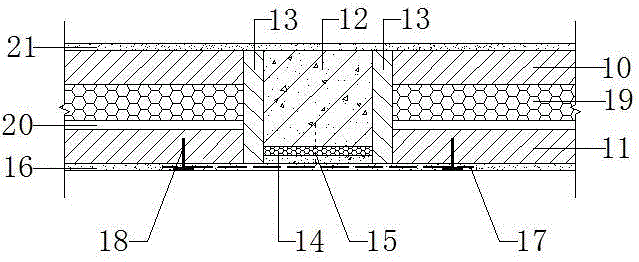

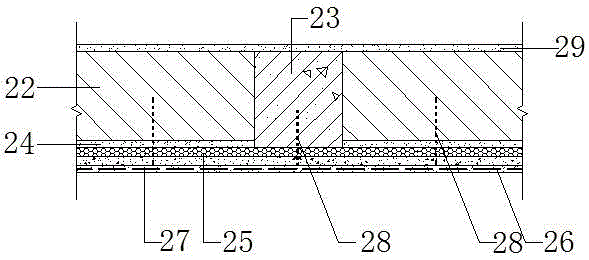

[0060] A green building self-insulation structure system, comprising a green self-insulation wall and a green self-insulation floor or wall panel; Load-bearing self-insulating walls, non-load-bearing self-insulating walls, sandwich self-insulating walls, and pasted self-insulating walls composed of composite self-insulating components ("self-insulating components" for short);

[0061] The "self-insulating masonry" includes load-bearing self-insulating masonry, non-load-bearing self-insulating masonry, sandwich self-insulating masonry, and pasted self-insulating masonry;

[0062] The load-bearing self-insulating masonry is a masonry composed of load-bearing lightweight energy-saving bricks (blocks) and lightweight mortar; the non-load-bearing self-insulating masonry is composed of non-load-bearing lightweight energy-saving bricks (blocks), lightweight The masonry composed of mortar masonry; the sandwich self-insulating masonry, which is composed of light energy-saving bricks (b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com