Combined type steel pipe concrete special-shaped column with honeycomb-hole partition plate

A technology of steel pipe concrete and honeycomb holes, which is applied in the direction of columns, pier columns, pillars, etc., can solve the problems of weakening the combined effect of steel and concrete, unrealized structural combination, complex steel concrete structure, etc. The effect is obvious and beneficial to the performance of the cross section

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

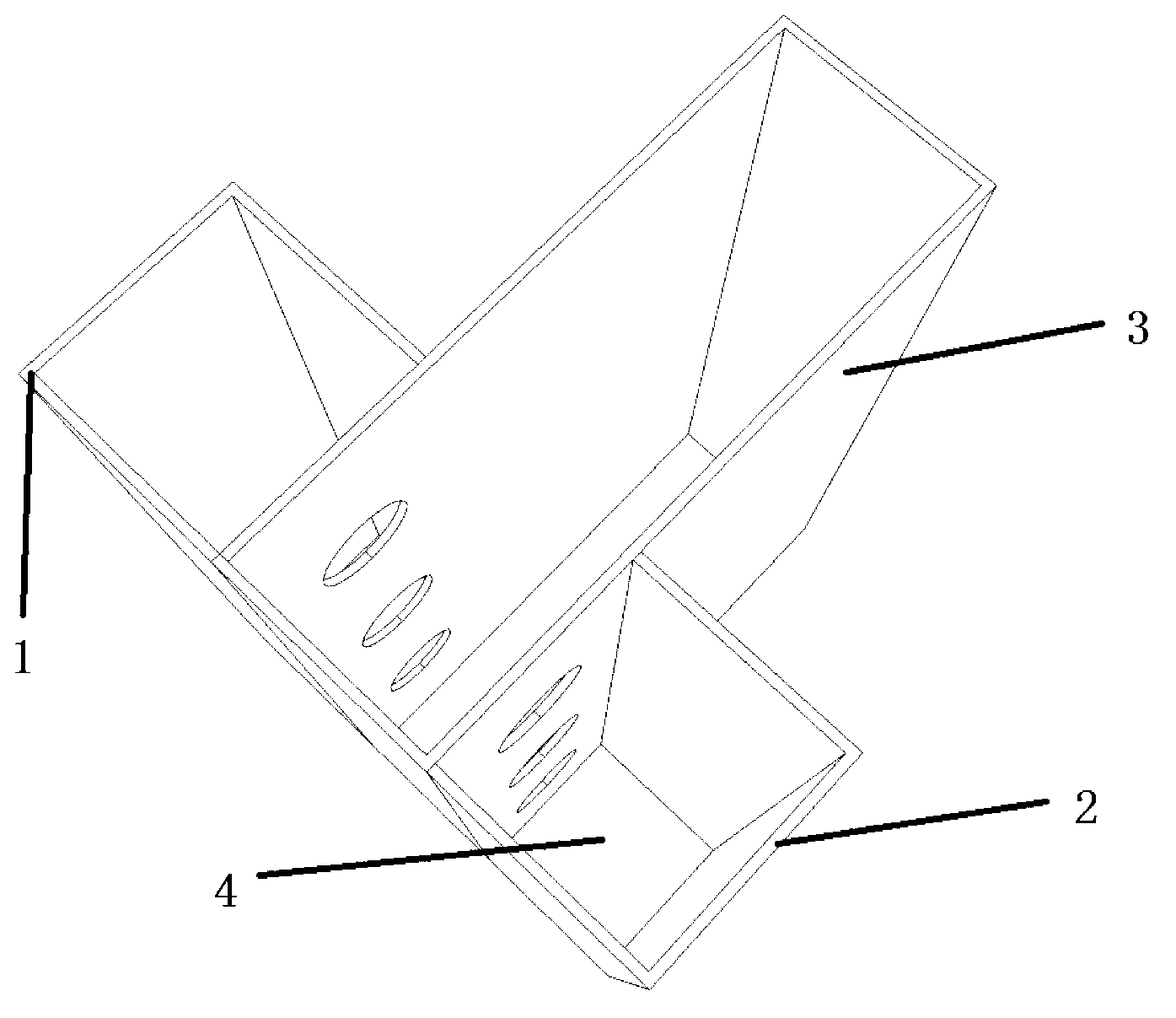

[0025] figure 1 What is shown is a combined T-shaped concrete-filled steel pipe special-shaped column, which is a side column of a special-shaped column frame structure. Under complex stress, circular honeycomb cells have relatively uniform peripheral stress, and the stress concentration phenomenon is weaker than other forms of cell shapes; and polygonal honeycomb cells can improve concrete and steel partitions due to uneven edges and corners along the perimeter. interaction between. U-shaped steel 1 and U-shaped steel 2 can be formed by bending steel plates or welding steel plates; on rectangular steel pipes, the opposite long-side steel plate walls are used as the objects for opening honeycomb holes, and the two rows of holes are close to the short side of one side. , using means such as oxygen cutting to cut and form the pre-determined hole shape, and there is a certain distance between the holes along the vertical direction of the column; the U-shaped steel 1 and the U-sh...

Embodiment 2

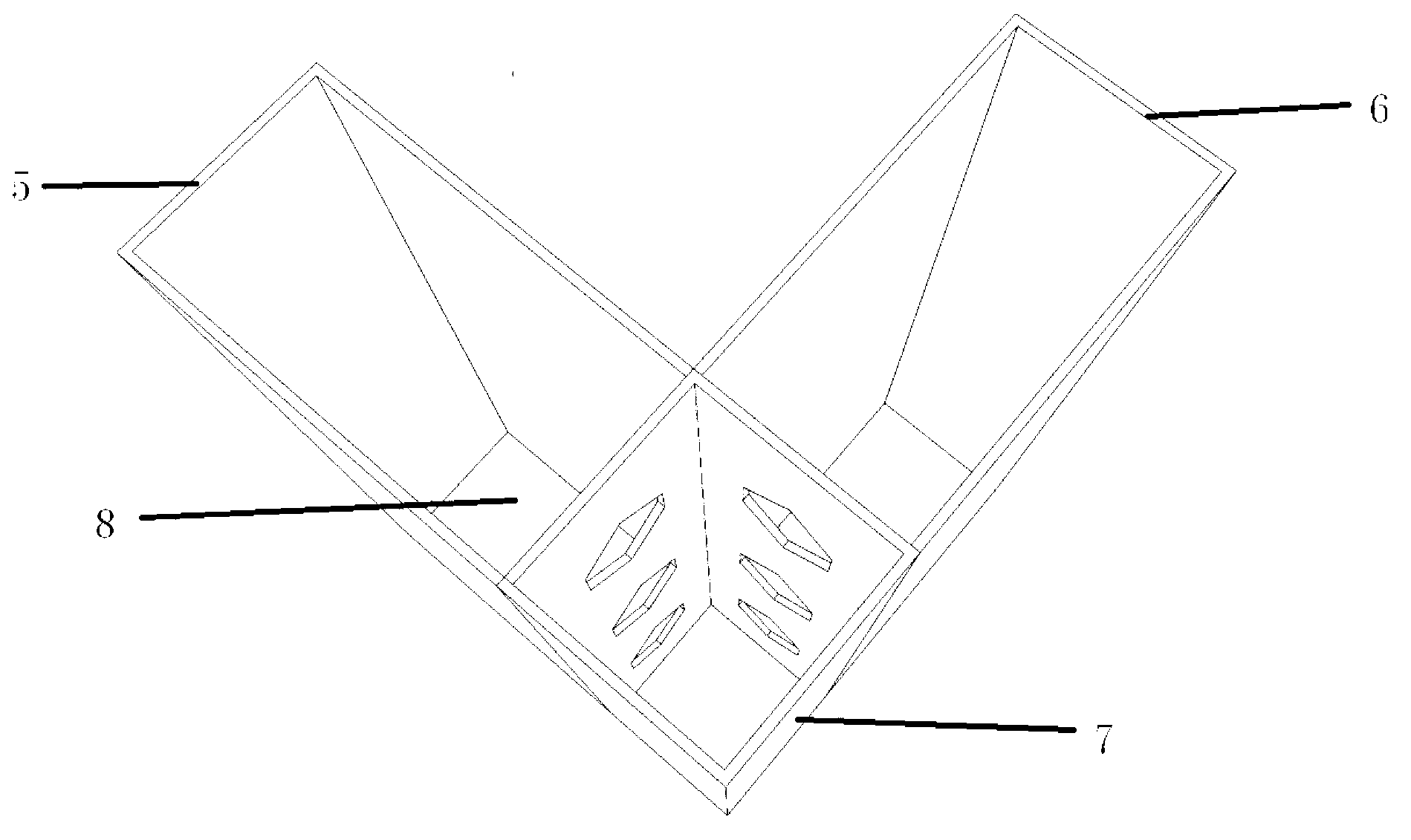

[0027] figure 2 The combined L-shaped concrete-filled steel pipe special-shaped columns with polygonal honeycomb hole partitions are shown, which are corner columns of the special-shaped column frame structure. Under complex stress, circular honeycomb cells have relatively uniform peripheral stress, and the stress concentration phenomenon is weaker than other forms of cell shapes; and polygonal honeycomb cells can improve concrete and steel partitions due to uneven edges and corners along the perimeter. interaction between. U-shaped steel 5 and U-shaped steel 6 can be formed by bending steel plates or welding steel plates; on square steel pipes, the steel plate walls on both sides are used as the objects for opening honeycomb holes, and the pre-determined hole shapes are cut by oxygen cutting and other means. Forming, with a certain distance between the holes in the vertical direction of the column; U-shaped steel 5 and U-shaped steel 6 are respectively welded to each honeyc...

Embodiment 3

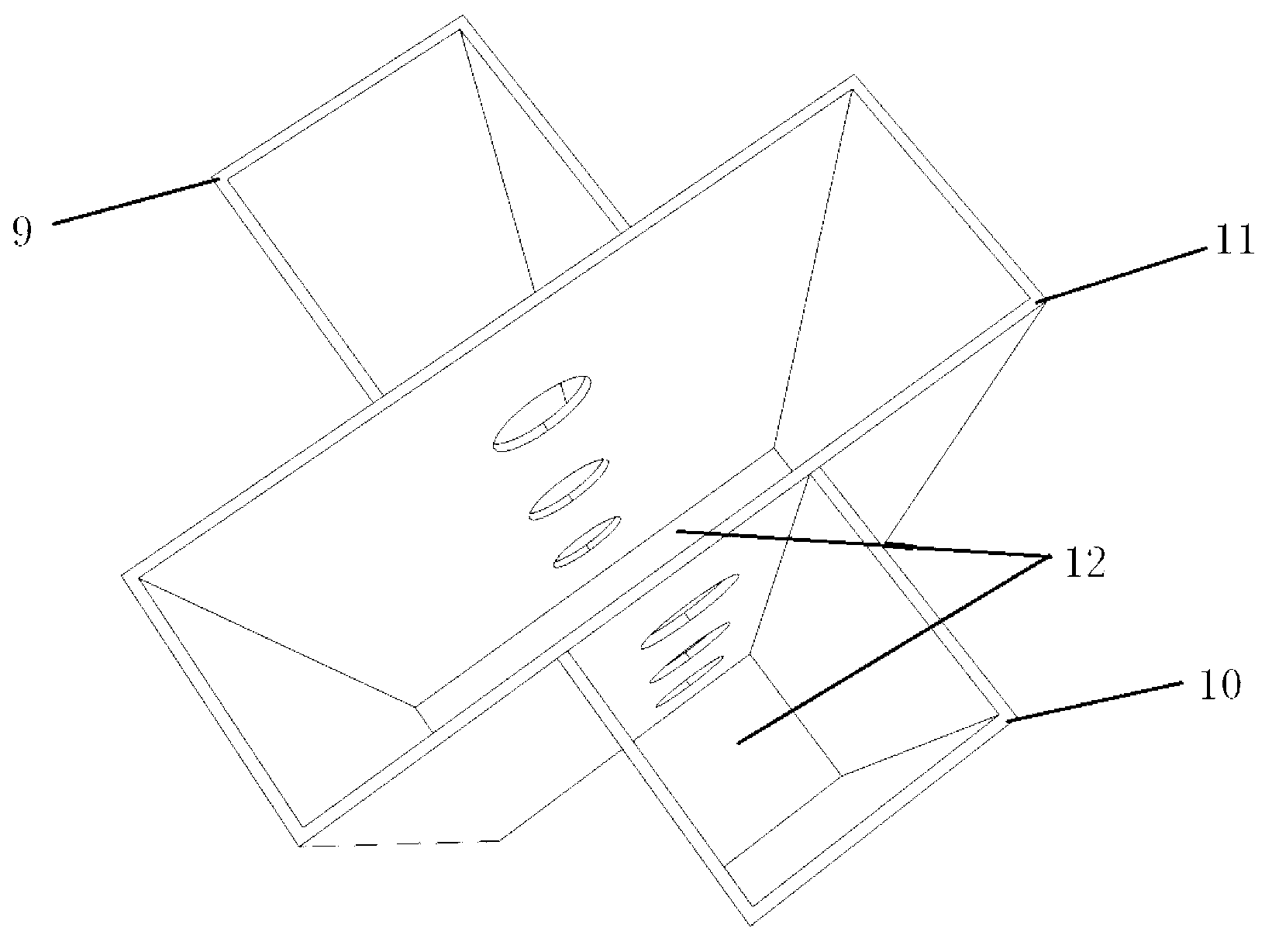

[0029] image 3 It shows the combined ten-shaped concrete-filled steel pipe special-shaped columns with circular honeycomb hole partitions, which are the inner columns of the special-shaped column frame structure. Under complex stress, circular honeycomb cells have relatively uniform peripheral stress, and the stress concentration phenomenon is weaker than other forms of cell shapes; and polygonal honeycomb cells can improve concrete and steel partitions due to uneven edges and corners along the perimeter. interaction between. U-shaped steel 9 and U-shaped steel 10 can be formed by bending steel plates or welding steel plates; on rectangular steel pipes, the opposite long-side steel plate walls are used as the objects for opening honeycomb holes, which are all arranged on the central axis, and are cut by oxygen cutting, etc. The method is to cut and shape the pre-determined hole shape, and keep a certain distance between the holes along the vertical direction of the column; t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com