Hollow fiber membrane assembly pouring device and method thereof

A fiber membrane and membrane module technology, applied in the field of membrane separation, can solve the problems of high equipment sealing and material requirements, changing the shape of the mold and the way of glue feeding, without considering the influence of the impregnating liquid, etc., to improve the pouring quality and shorten the Effect of degassing time and reduction of production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

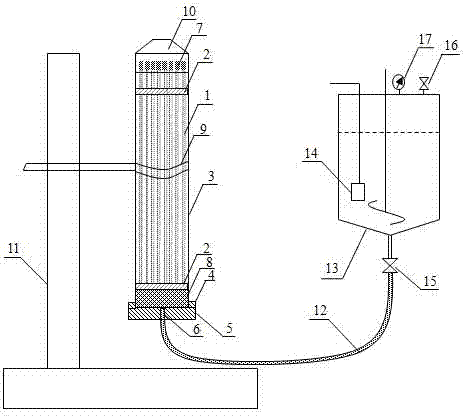

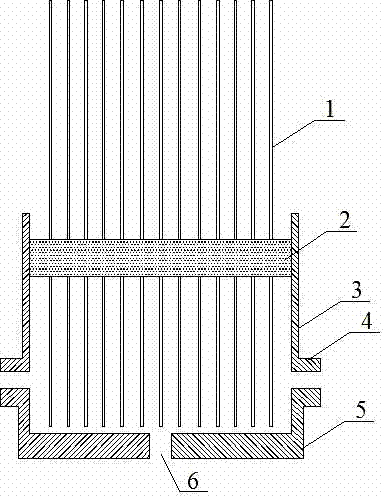

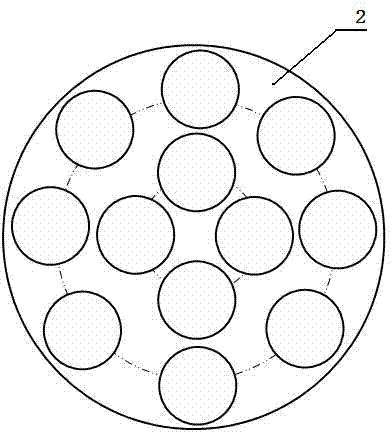

Embodiment 1

[0033] Using the method for casting hollow fiber membrane modules disclosed in the present invention, using paraffin as a sealant to block the two ends of the membrane filaments, the viscosity of the adhesive used is 700cp, the frequency of the ultrasonic device used is 160KHz, and the power is 800W. Ultrasonic degassing and The dispersion time is 20 minutes, the thickness of the flexible pad is 10mm, and the uniform number of openings of the flexible pad is 12. Three membrane modules were poured according to the above-mentioned specific operation process, namely module 1, module 2 and module 3. After casting, the hollow fiber membrane modules were cured at room temperature for 12 hours. After curing, remove the connecting piece between the mold and the membrane module casing, cut off the adhesive and hollow fiber membrane filaments on both ends of the membrane module casing, and then obtain a sealed membrane module at one end, and then pour the hollow fiber membrane module acc...

Embodiment 2

[0040] Using the method for pouring hollow fiber membrane modules disclosed in the present invention, gypsum is used as a sealant to block the two ends of the membrane filaments, the viscosity of the adhesive used is 900cp, the frequency of the ultrasonic device is 200KHz, the power is 900W, ultrasonic degassing and The dispersion time is 15 minutes, the thickness of the flexible pad is 15 mm, and the uniform number of openings of the flexible pad is 10. Three membrane modules were poured according to the above-mentioned specific operation process, namely module 1, module 2 and module 3. After casting, the hollow fiber membrane module was cured at room temperature for 15 hours. After curing, remove the connecting piece between the mold and the membrane module casing, cut off the adhesive and hollow fiber membrane filaments on both ends of the membrane module casing, and then obtain a sealed membrane module at one end, and then pour the hollow fiber membrane module according to ...

Embodiment 3

[0047] Using the method for pouring hollow fiber membrane modules disclosed in the present invention, using paraffin as a sealant to block the two ends of the membrane filaments, the viscosity of the adhesive used is 650cp, the frequency of the ultrasonic device is 55KHz, the power is 90W, ultrasonic degassing and The dispersion time is 20 minutes, the thickness of the flexible pad is 15 mm, and the uniform number of holes in the flexible pad is 10. Three membrane modules were poured according to the above-mentioned specific operation process, namely module 1, module 2 and module 3. After casting, the hollow fiber membrane module was cured at room temperature for 15 hours. After curing, remove the connecting piece between the mold and the membrane module casing, cut off the adhesive and hollow fiber membrane filaments on both ends of the membrane module casing, and then obtain a sealed membrane module at one end, and then pour the hollow fiber membrane module according to the a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com