Pier hydraulic leveling inner-climbing climbing form and concrete pouring method thereby

A flat internal climbing and concrete technology, which is applied in construction, water conservancy engineering, sea area engineering, etc., can solve the problems of difficult control of concrete temperature deformation, difficult guarantee of concrete pouring quality, hanging curtains, wrong platform, deformation, etc., and achieve overall stability Good, reasonable design, good effect of precision control system

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

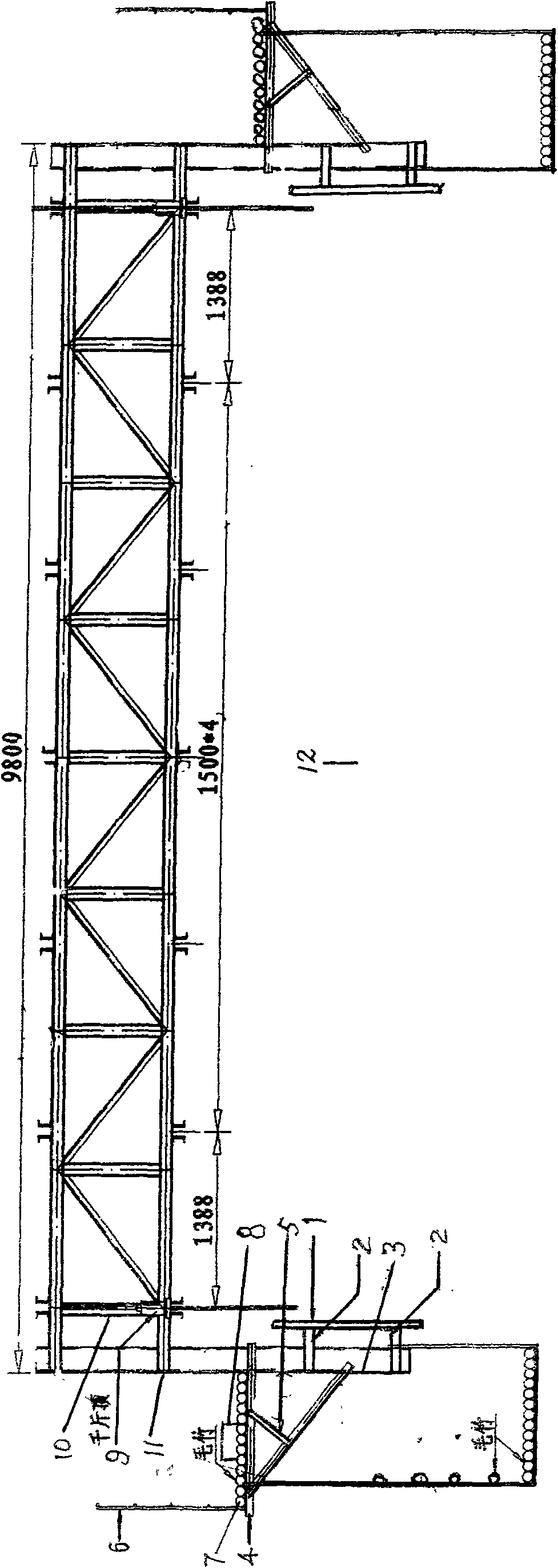

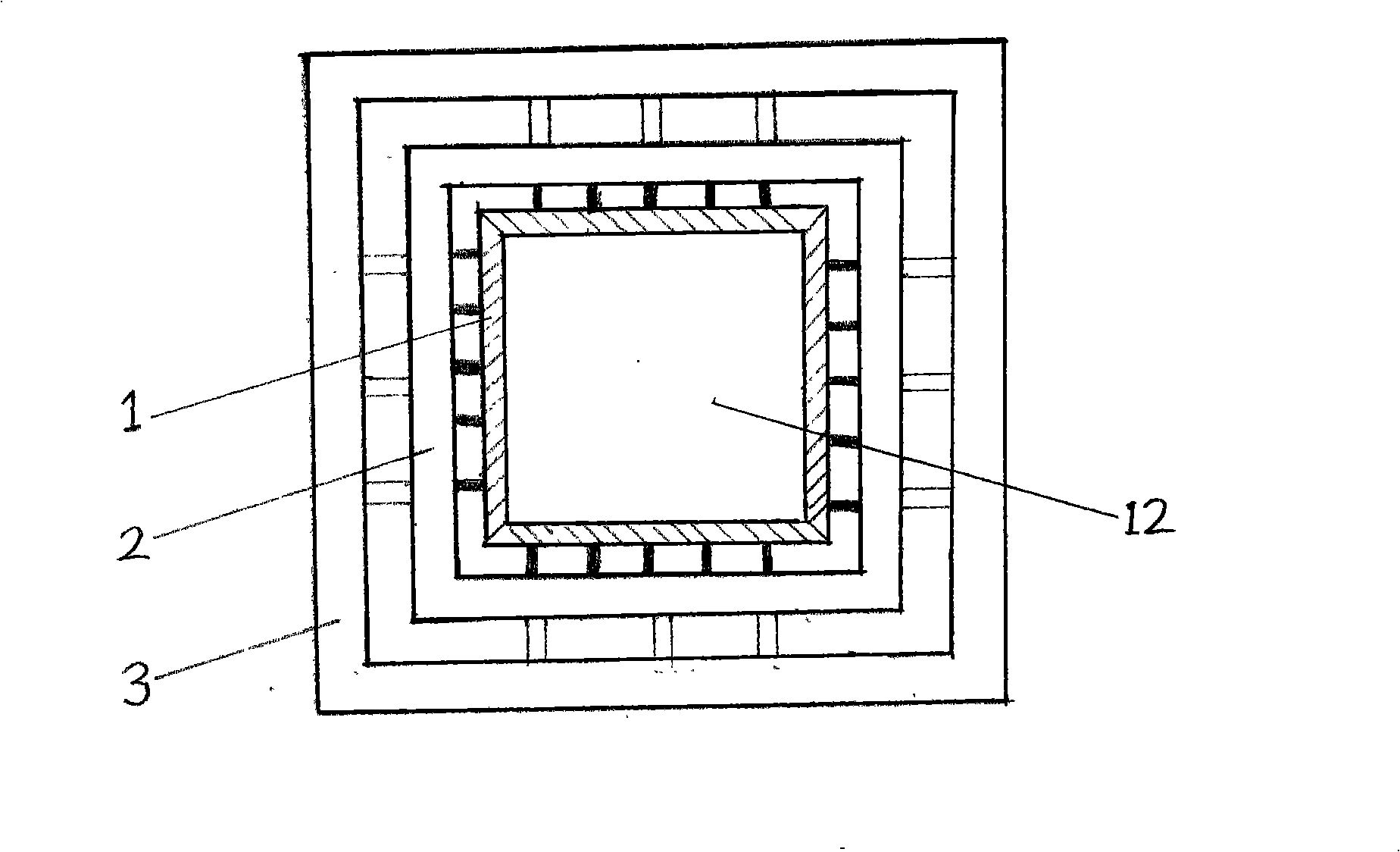

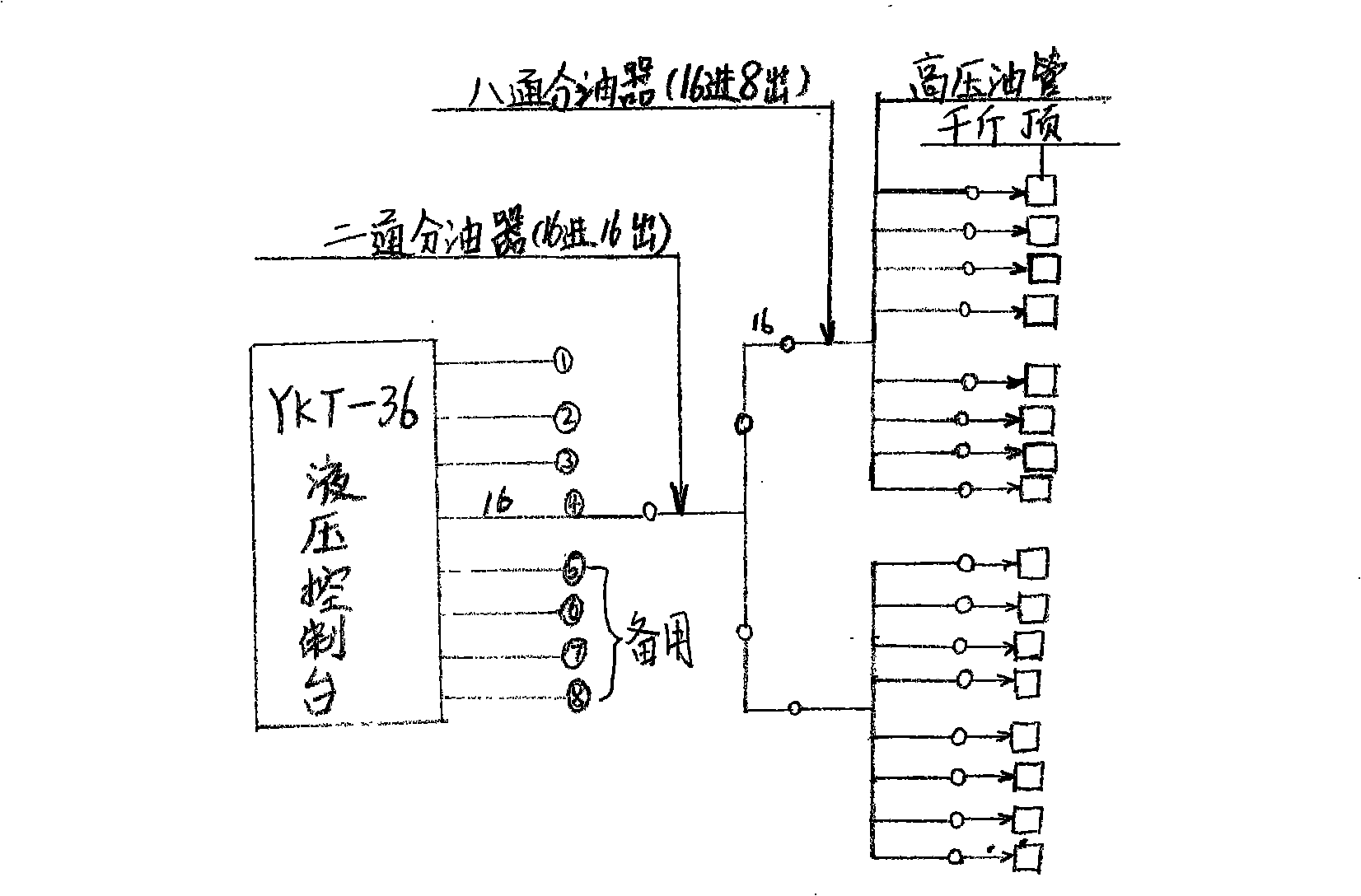

[0025] Example: Pier hydraulic leveling internal climbing sliding formwork and its method of pouring concrete

[0026] (1) The production of sliding formwork, the production steps are as follows:

[0027] 1. Assembling the main truss beams around the gate pier, the upper and lower beams of the main truss beams are made of [10 channel steel, the longitudinal vertical beams between the upper and lower beams, and the connecting beams are welded between the vertical beams, and the vertical beams are made of channel steel. The beam is angle steel, the upper and lower beams of the main truss beam are welded to the vertical bar of the lifting frame, and the enclosure is welded to the vertical bar of the lifting frame, and the four enclosures around the pier are welded into a square overall enclosure;

[0028] 2. Weld the pendant on the back of the steel formwork, and weld the four formworks into a square whole and hang them on the square enclosure, and then bind the steel bars of the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Release strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com