Construction method for combined V-shape steel pipe concrete pile

A technology of concrete-filled steel pipe columns and concrete-filled steel pipes, which is applied in the direction of columns, pier columns, pillars, etc., and can solve problems such as complexity, difficulties in the manufacture and installation of embedded parts and steel pipes, and many curved lines

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

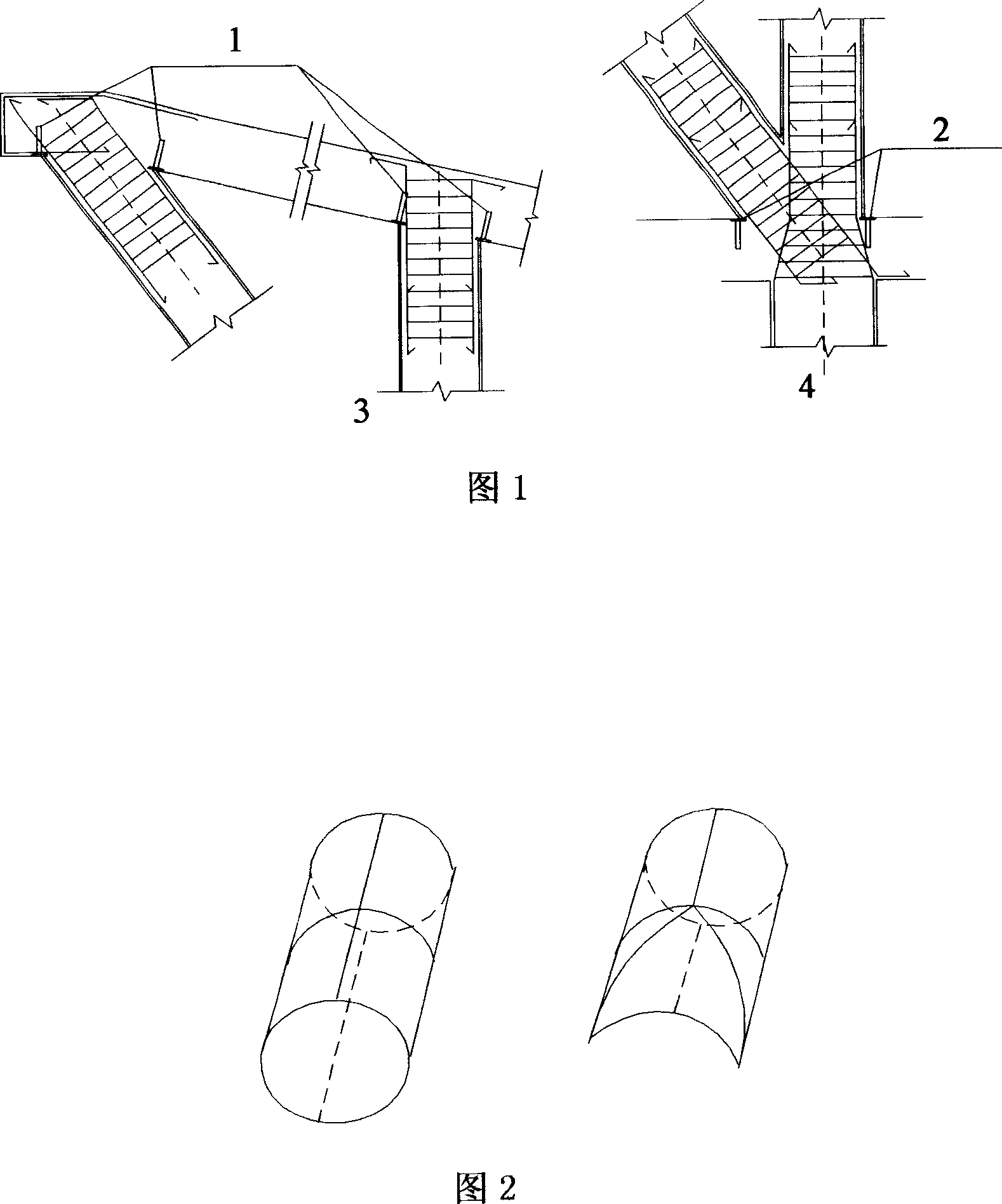

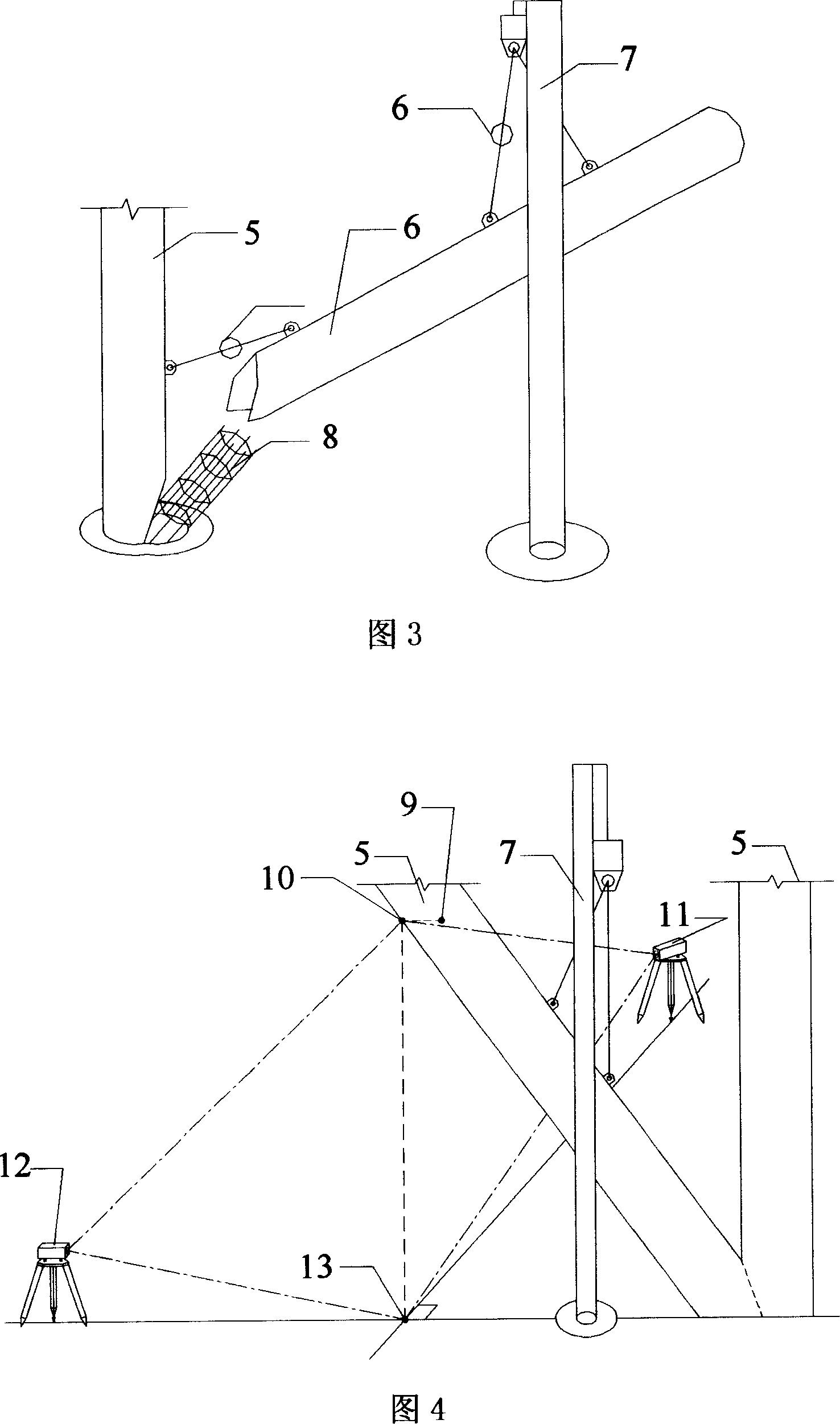

[0017] The specific implementation manner of the invention will be further described in detail below in conjunction with the accompanying drawings and embodiments. The combined "V"-shaped concrete-filled steel pipe column is located above the reinforced concrete floor structure at an elevation of 26.2m outside the H-axis of the east and west areas of the main stadium of the Nanjing Olympic Sports Center. The length of the inclined column is from 14m to 20m, the vertical column is about 15m high, the outer diameter of the steel tube concrete column is 1000mm, and the wall thickness of the steel tube is 18mm. The top of the CFST column intersects with the 44.28m high reinforced concrete ring beam. The angle between the inclined fork steel pipe and the vertical steel pipe ranges from 20° to 32°. The technical scheme of the present invention is created in the actual construction of this project. For the problems of making and installing embedded parts, anchoring steel bars, stee...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com