Pitched roof concrete construction method

A construction method and concrete technology, applied in the direction of roof, formwork/formwork/work frame, formwork/formwork/work frame connectors, etc., can solve the problems of concrete honeycomb pores, concrete slide, roof leakage, etc., to achieve High density, good construction quality, and the effect of preventing leakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 2

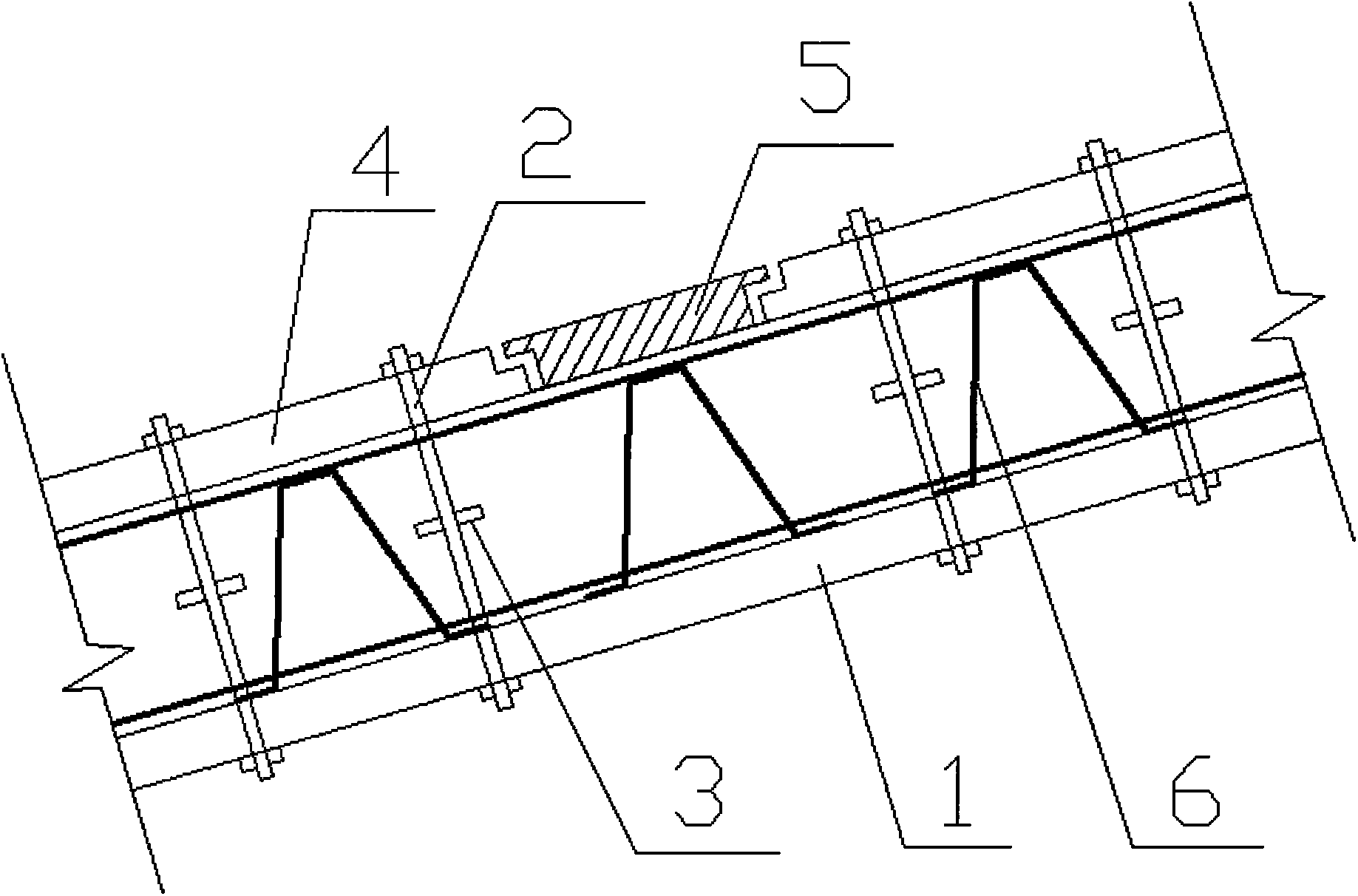

[0021] A construction area of a project is 830M 2 , is a three-story frame structure building with a roof slope of 35°, a total length of the sloped roof of 42m, and a roof panel thickness of 120mm.

[0022] This embodiment adopts the construction method of double-sided mold sealing. By supporting the bottom form 1 and top form 4 of the sloping roof, the concrete pouring has certain constraints under the condition of slope. The short steel bar is used between the bottom form 1 and the top form 4 of the sloping roof The bracket is used to ensure the thickness of the concrete slab. The diameter of the short steel bar is 22mm. The top form 4 and the bottom form 1 are connected as a whole by the tension bolt 2. The diameter of the tension bolt 2 is 14mm. A water stop ring 3 is set in the middle of the bolt 2 to prevent leakage. The diameter of the water stop ring 3 is 45 mm. A steel bar stool 6 is set on the bottom form 1 to place the upper negative rib skeleton to prevent the n...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com