Construction method of foundation pit support

A construction method and technology of foundation pit support, which can be applied in basic structure engineering, excavation, construction, etc., can solve the problems of differential settlement and structural damage between the underground diaphragm wall and the main structure, and achieve the effect of reducing the cost and speeding up the construction period

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 2

[0027] A commercial building has 28 floors, the building height is 98m, and the total construction area is about 105,000 square meters. There are 2 floors in the basement. , The building foundation adopts bored piles.

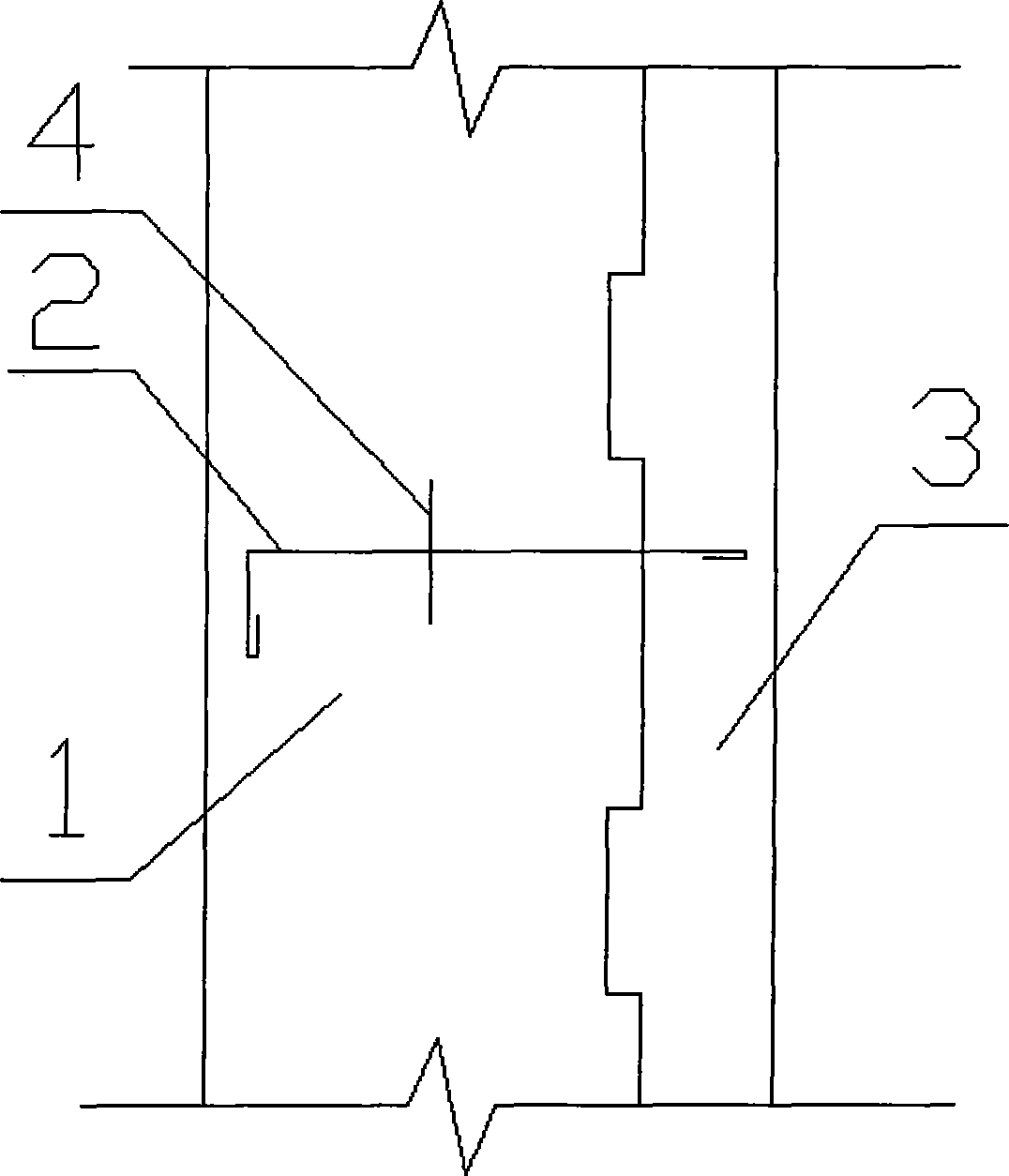

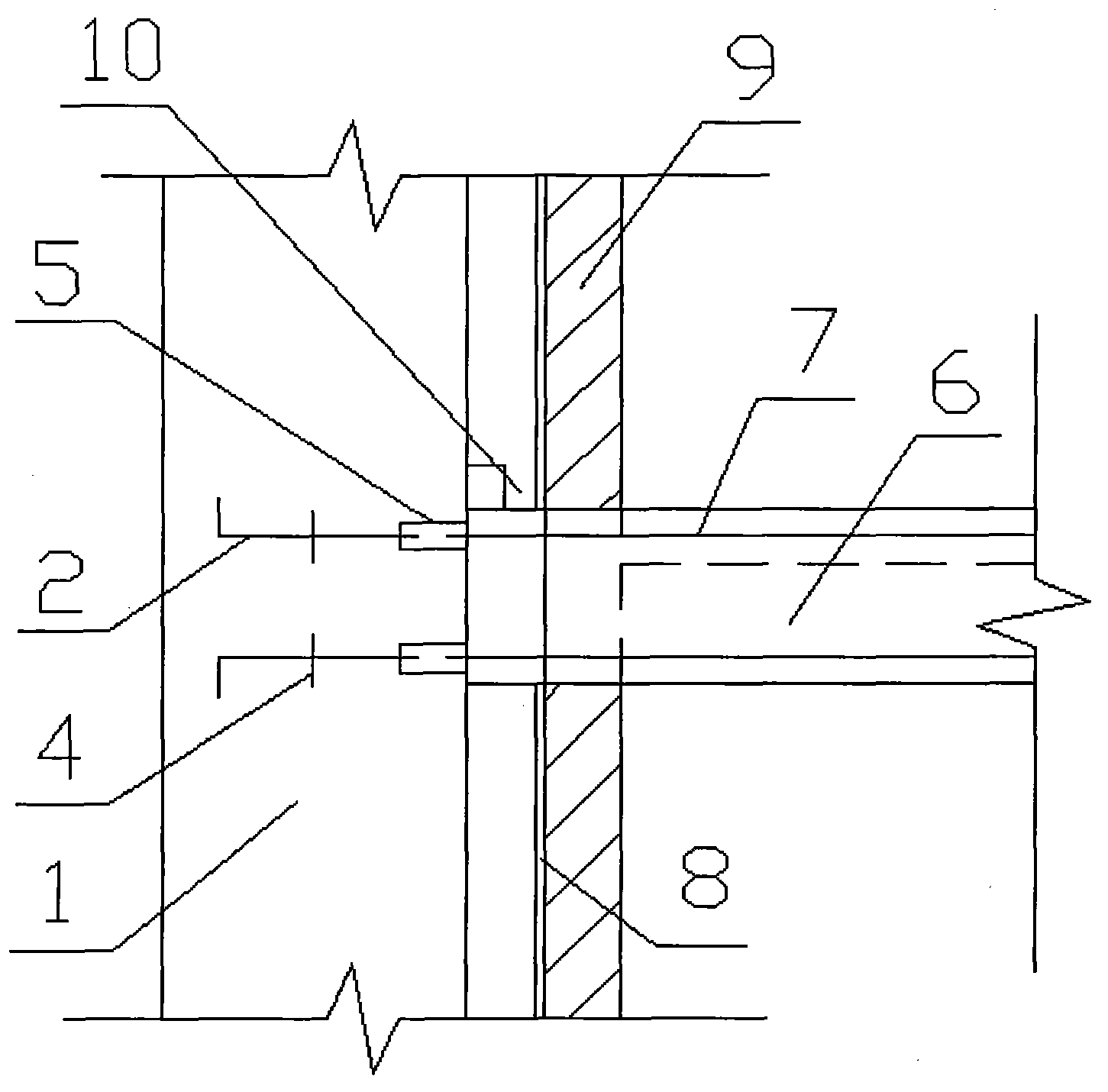

[0028] In this embodiment, the underground diaphragm wall 1 around the foundation pit and the temporary columns in the pit are used as the vertical load-bearing system, and the beam plate of the basement's own structural layer is used as the inner support of the foundation pit enclosure, with ±0.00 as the starting surface or the underground The first floor is the starting surface, the construction of the underground structure is carried out from top to bottom, and the construction of the upper main structure is carried out from bottom to top at the same time, forming a parallel three-dimensional operation of the upper part and the lower part. In order to facilitate earthwork excavation and vertical transportation, the concrete of the rib beam of the underground...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com