Super deep underground diaphragm wall deformation automatic real-time monitoring device and operating method thereof

An underground diaphragm wall and real-time monitoring technology, which is applied in basic structure engineering, construction, and basic structure tests, can solve the problems of safety accidents in foundation pit engineering, low efficiency and difficulties in inclinometer monitoring, and improve monitoring frequency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

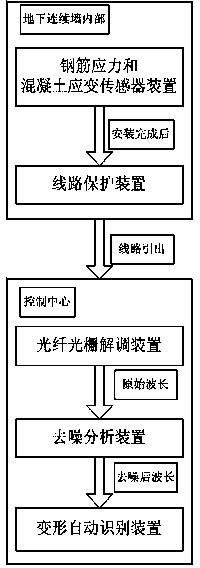

[0045] Embodiment: Taking the ultra-deep underground diaphragm wall deformation monitoring of a subway air shaft in a certain area as an example, see figure 1 , the specific application is carried out according to the following steps:

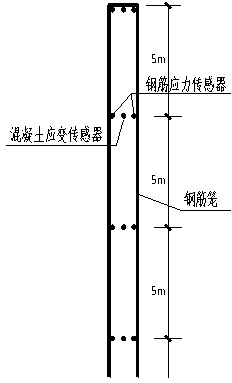

[0046] Project overview: The ground elevation is about 26.27m, the outsourcing size is 11.4×27.7m (including the thickness of the enclosure wall), the excavation depth of the foundation pit is 47.987m, and the enclosure structure adopts a 1.5m-thick underground diaphragm wall with a depth of about 70m. There are eleven reinforced frame beams and inner lining walls in the air shaft, and the composite wall structure is adopted with the diaphragm wall. The reinforced frame beams and inner lining walls are constructed by the reverse construction method. Structure, the diaphragm wall bears all the loads together with the operation phase and the main structure during the excavation phase of the foundation pit. The overburden in the field is mainly Q...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com