Construction method of ultra-deep underground diaphragm wall in water-rich soft-soil area

A construction method and soft soil technology, applied in sheet pile wall, foundation structure engineering, construction, etc., can solve the problem of slip cracking or collapse of groove wall

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

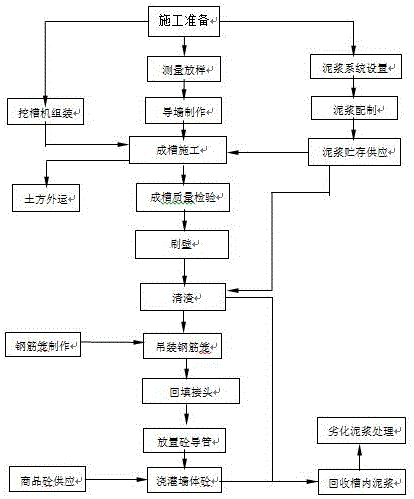

Method used

Image

Examples

Embodiment 1

[0091] This embodiment is applied in the construction process of the ultra-deep underground diaphragm wall in water-rich soft soil areas.

[0092] In this embodiment, the underground space connection project is set as an underground four-story project, and the foundation pit excavation depth is 34m. For excavation construction, the main enclosure structure adopts a 58m deep underground diaphragm wall, the wall thickness is 1.2m, the maximum weight of the steel cage is 116T, and the width is 4.5-6m, a total of 72 pieces. Among them, one-character frame, four Z-character frames, and four L-character frames. H-shaped steel joints are adopted. The area 8m below the bottom of the foundation pit is reinforced with a ground diaphragm wall lattice, and an underground diaphragm wall is set at an interval of 21m in the horizontal direction, with a total of 7 diaphragm walls and 21 diaphragm walls.

[0093] The geological conditions of the project are distributed from top to bottom as ...

Embodiment 2

[0132]This embodiment is applied in the process of configuration and use of wall protection mud.

[0133] The engineering parameters and geological parameters set in this embodiment are the same as those in Embodiment 1.

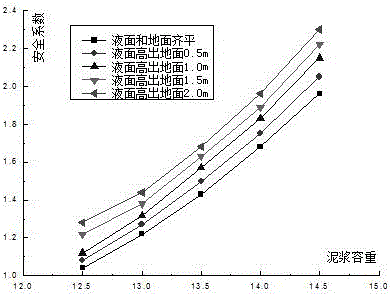

[0134] During the construction of the underground diaphragm wall, the key process is to excavate the groove. When forming the groove, mud needs to be used to protect the wall, carry slag, cool and lubricate the drilling tools and other functions. The mud should have a series of properties such as physical stability, chemical stability, suitable fluidity, good mud skin forming ability, and appropriate density, in order to meet the above functional requirements. Therefore, scientific configuration and correct use of mud are the key to ensure groove formation.

[0135] (1) Mud preparation

[0136] For the layout of the mud station, due to the complex geological conditions of the ultra-deep underground diaphragm wall to be constructed and the tight constructio...

Embodiment 3

[0170] This embodiment is used in the construction stage of trench excavation.

[0171] The engineering parameters and geological parameters set in this embodiment are the same as those in Embodiment 1.

[0172] Select the appropriate grooving machine. According to the excavation method, the grooving machines include: multi-head auger, punching grab, impact drill, multi-head drill, wheel milling type, disc milling type (milling type), etc.

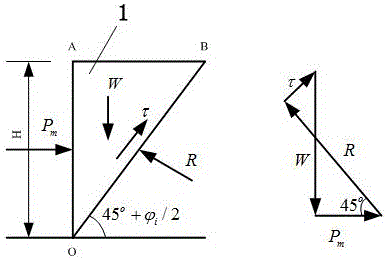

[0173] The continuous excavation process is used for the construction of the diaphragm wall. In order to ensure the balance of the adjacent conditions on both sides when the trencher cuts the soil, and to ensure that the trench wall is vertical, the diaphragm wall construction plans to use the trench-hopping method. According to the length of the trench section and the The opening width of the slot machine determines the first opening width and the closing width. When using a grab bucket to dig a groove, to make the slot hole vertical, th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com