Air source cooling and heating machine

A technology of cooling and heating machines and air sources, which is applied in air conditioning systems, mechanical equipment, and prevention of condensed water. It can solve the problems of indoor ground condensation, high construction costs, and unfavorable building structure safety, etc., and achieves the advantages of simple installation and outstanding environmental protection significance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

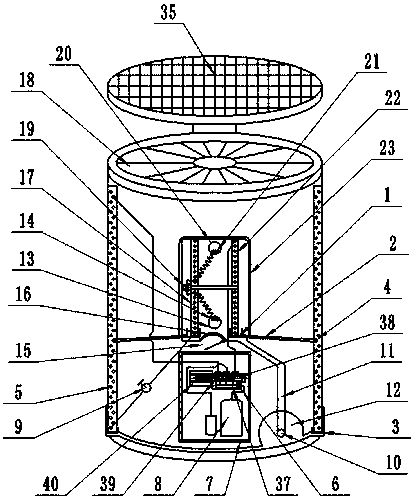

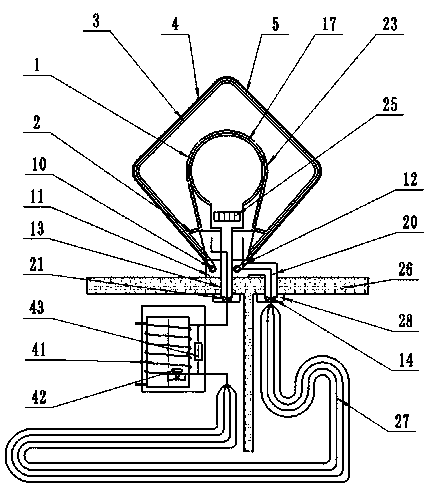

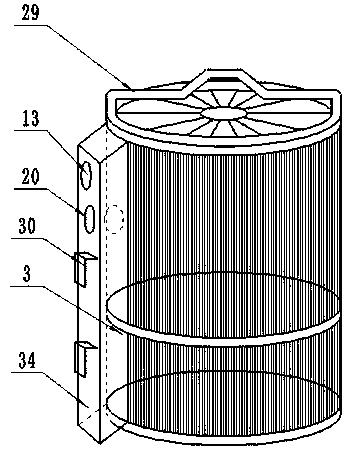

[0041] combine figure 1 , figure 2 , image 3 The working principle of the present invention is further described:

[0042] In this embodiment, the outdoor heat exchanger 5 adopts a ring structure, which can be a ring shape or a regular polygon, and a baffle 34 is provided at the gap of the ring structure; In the central area of the heat exchanger 5, there is a heat exchange air duct between the heat exchanger shell 23 and the lining fiber 7 and the outdoor heat exchanger 5; An external machine installation handle 29 is provided, and the ratio of the transverse length of the notch of the annular structure to the total circumference of the annular structure cross section is: I: L=1:1 / 20~1 / 4; where: I is the ring L is the transverse length of the notch of the annular structure; L is the total perimeter of the cross-section of the annular structure; the outdoor heat exchanger 5 is provided with a coating for absorbing sunlight and heat.

[0043] The indoor heat exchanger h...

Embodiment 2

[0058] combine Figure 4 The sectional structure diagram of the unit with cascaded fans and soil source interface further discusses the working principle.

[0059] and figure 1 figure 2 image 3 Compared with Embodiment 1, an annular cascaded fan 31 is provided at the lower part of the outdoor heat exchanger 5 , and its power is generally smaller than that of the outdoor exhaust fan 18 . The throttling component 9 passes through a switching interface and a pipe connection valve 33 for the soil source heat exchange fluid. The upper port of the outdoor heat exchanger 5 is connected to the soil source heat exchange gas pipe connection valve 32 through a branch manifold, and other various parts are connected with the valve 32. figure 1 figure 2 image 3 same. It is also suitable for making larger size and higher power products, especially suitable for villas, small offices and other places.

[0060] Annular cascade fan 31, soil source heat exchange fluid pipe connection ...

Embodiment 3

[0063] Figure 5 It is a structural diagram of the outdoor machine of the present invention to condense water, dissipate heat, dissipate heat and exchange air. Among them: the features corresponding to the labels 1-29 are the same as figure 1 figure 2 image 3 The same, except that the external heat exchanger and the casing are of traditional structure. The purpose of this design is to use many molds in the external unit of the air conditioner in the existing factory, which greatly reduces the cost. Refrigerants bring huge environmental benefits. The working principle is the same as that of Embodiment 1, and will not be repeated here.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com