Robot automatic welding workstation for large tank and welding method using robot automatic welding workstation for large tank

An automatic welding and robot technology, applied in the direction of auxiliary equipment, welding equipment, welding equipment, etc., can solve the problems that the welding quality cannot fully meet the welding process of the tank body, the range of welding process is single, and the automatic welding cannot be realized, so as to achieve spatial movement The effect of flexibility, small deformation and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

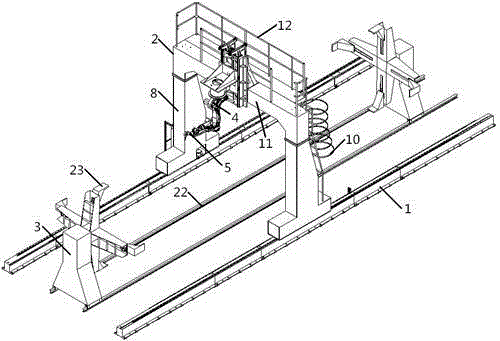

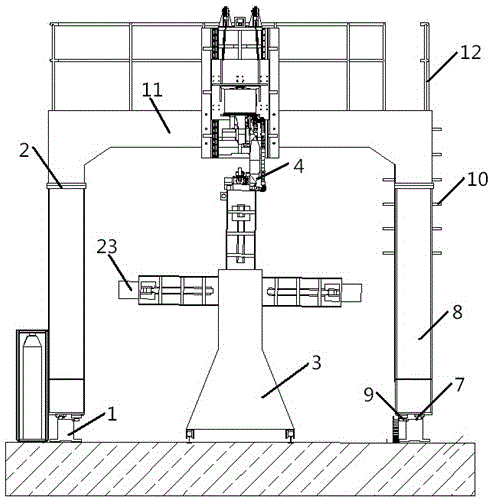

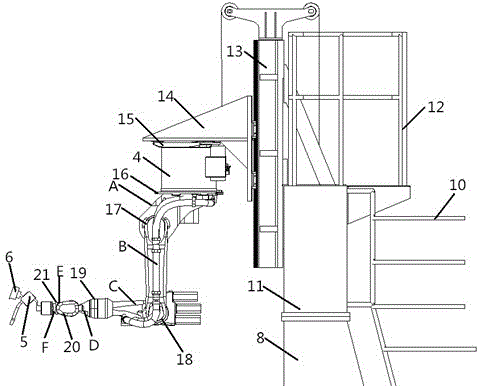

[0026] see Figure 1-Figure 4 , a large-scale robot automatic welding workstation, including a welding system and a PLC automatic control system, the PLC automatic control system is connected to the welding system through a network bus, and the welding system includes a slide rail 1, a positioner 3 and a machine Frame 2, the slide rail 1 is installed on the ground base, the slide rail 1 is connected with the column 8 through the guide rail slider 7, at the same time, the column 8 and the slide rail 1 are driven by the rack and pinion transmission system 9, and the column 8 is realized. Move on the slide rail 1 (the X-axis of the machine tool moves), a ladder 10 is installed on the column 8, the column 8 is connected to the beam 11 through bolts, the guardrail 12 is installed on the beam 11, and the Z-axis slide seat of the machine too...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com