Mould surface induction quenching machine tool

A surface induction and quenching machine tool technology, applied in quenching devices, forming tools, manufacturing tools, etc., can solve the problems of not meeting the requirements of the heat treatment process on the surface of the mold, reducing the accuracy and service life of the mold, and easily producing oxide scale on the surface of the mold. The effect of flexible space action, small deformation and simple structure

Active Publication Date: 2010-11-24

HUBEI QIXING MOLD MFG

View PDF0 Cites 1 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

In the prior art, two methods are usually used for mold surface heat treatment: ① flame quenching method, the main disadvantage of flame quenching is that the heating time is long, the deformation of the mold is large, and oxide scales are easily produced on the surface of the mold, which affects the precision of the mold The quality of flame quenching cannot be guaranteed, and the work efficiency is low and it is difficult to carry out large-scale production; moreover, it is difficult to control the flame quenching temperature, the uniformity of the quenching surface is poor, and problems such as too low hardness and cracking are prone to occur, thereby reducing the precision and service life of the mold

②Using laser heat treatment numerical control equipment for quenching, due to the laser spot itself, the heat treatment process is lengthy, the processing efficiency is low, and the laser quenching depth is generally between 0.05-0.20mm, which cannot meet the process requirements of mold surface heat treatment

Since the laser spot cannot stay on the same part of the workpiece twice, programming and operation are also very troublesome

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

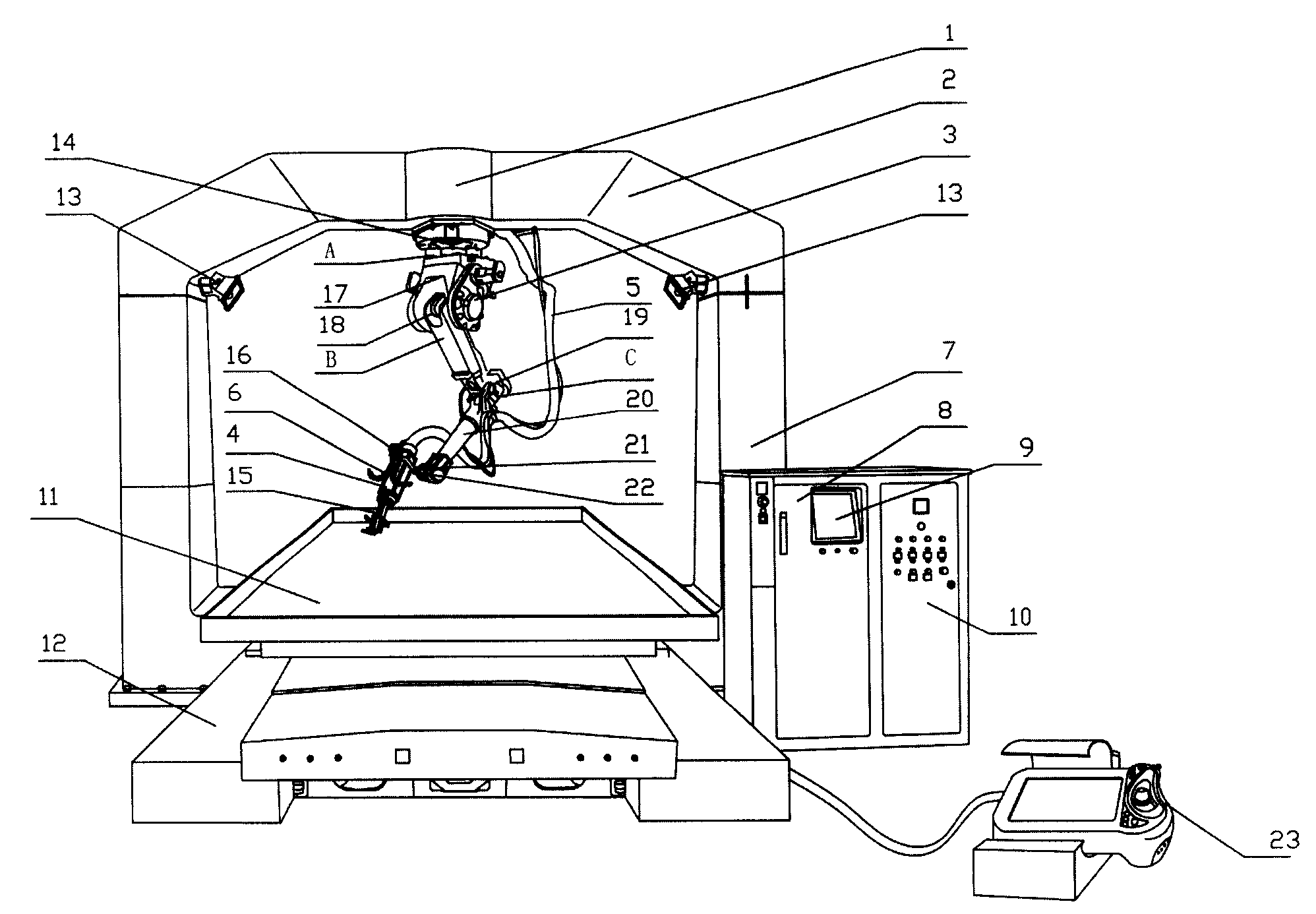

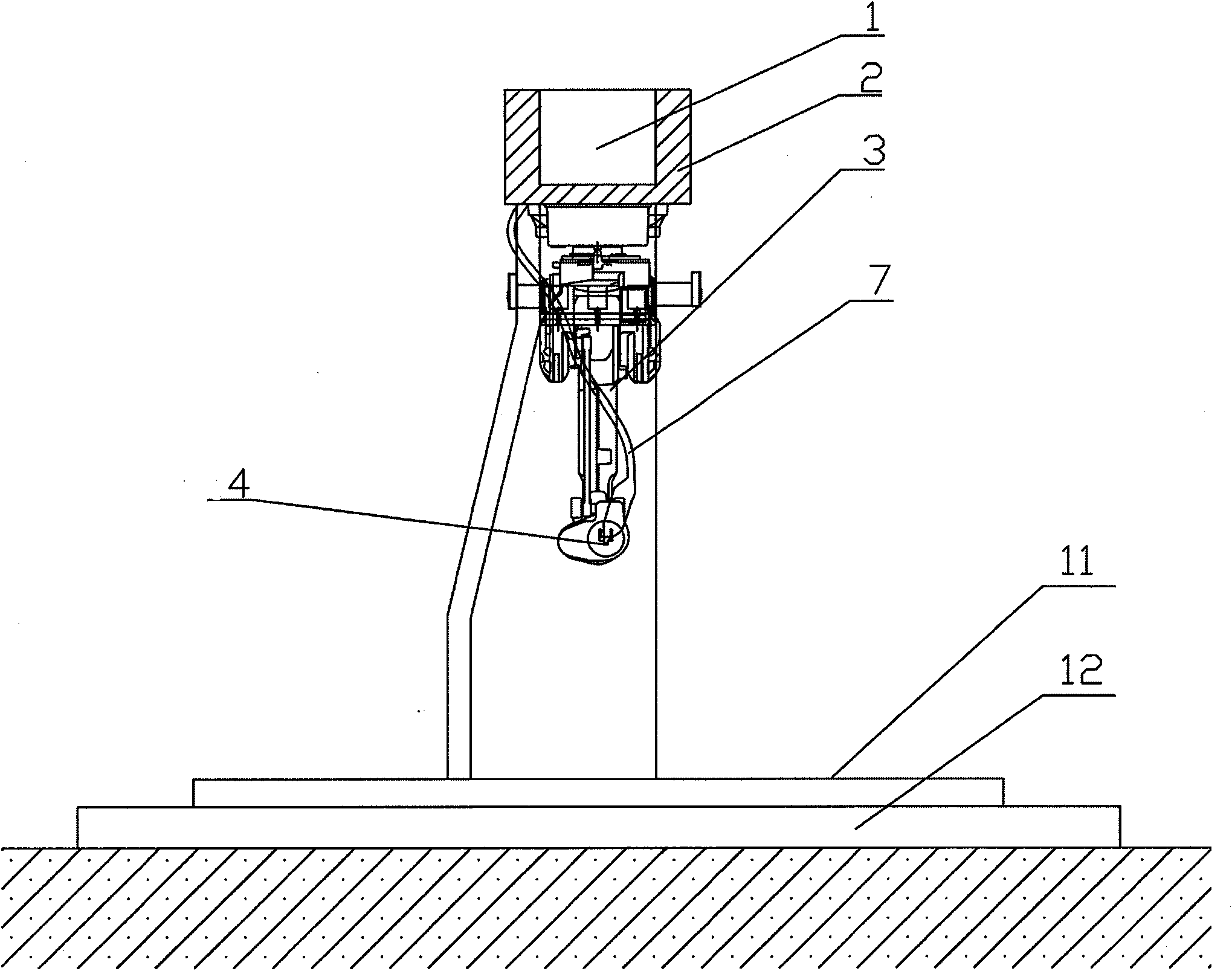

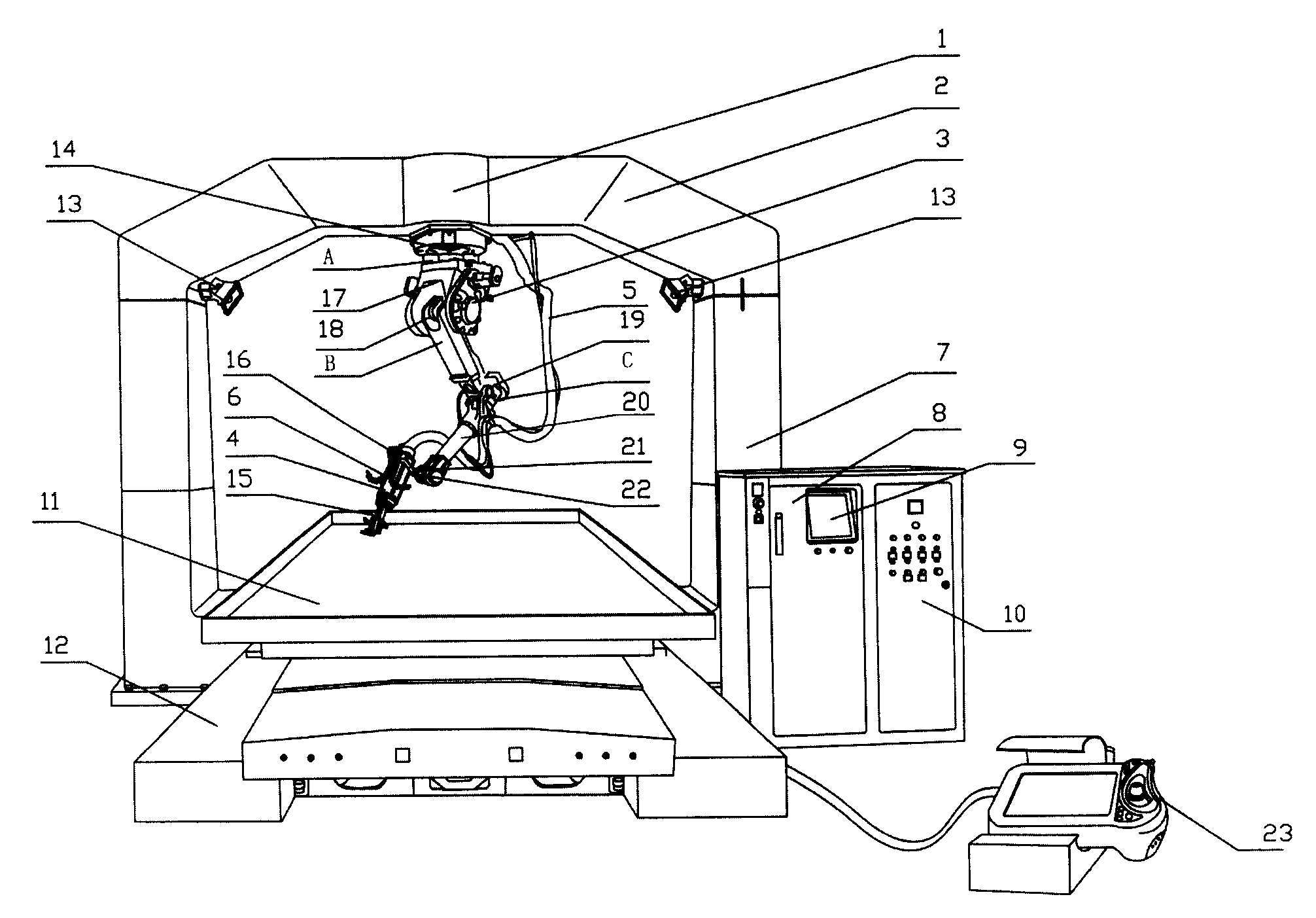

Login to View More Abstract

The invention relates to a mould surface induction quench machine tool, comprising a base, a workbench and a frame; a six-shaft linked manipulator is arranged above the workbench by the frame; the tail end of the manipulator is connected with a transformer on the sixth rotary shaft by a connecting base; the output terminal of the transformer is connected with an induction coil and provided with acooling water pipe; the input terminal of the transformer is connected with a medium-high frequency converter by the induction coil. The induction quench machine tool has uniform quenching surface, high machining precision, good processing quality of workpiece and small deformation; moreover, the space action of the six-shaft linked manipulator is flexible, so that the induction coil can be movedto every part of processing workpiece and various complicated curved surfaces can be processed by induction quenching. The invention has quick heating speed, high processing efficiency, easy control and convenient application and operation, and can be suitable for surface quenching of medium-and-large-sized stamping moulds; and the invention has the characteristics of simple structure, reasonableconfiguration, low manufacturing cost, high working stability, big work area and good safety.

Description

Mold Surface Induction Hardening Machine Tool technical field The invention relates to a mold surface induction hardening machine tool for quenching various mold surfaces by utilizing the principle of medium and high frequency induction heating metal surfaces, and belongs to the technical field of metal material surface heat treatment equipment. Background technique Dies used for sheet metal stamping, especially medium and large sheet metal stamping dies, in order to ensure the stamping quality and the service life of the die, the surface of the die must be quenched to increase the hardness of the die surface. In the prior art, two methods are usually used for the heat treatment of the mold surface: ① flame quenching method, the main disadvantage of flame quenching is that the heating time is long, the deformation of the mold is large, and the scale is easy to form on the surface of the mold, which affects the precision of the mold The quality of flame quenching cannot be ...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Patents(China)

IPC IPC(8): C21D1/62C21D1/42B21D37/10

CPCY02P10/25

Inventor 江正平张勤俭杨永康郭明阳

Owner HUBEI QIXING MOLD MFG

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com