Polysilicon crushing device

A crushing device and polysilicon technology, applied in grain processing and other directions, can solve problems such as insecurity, achieve the effects of convenient control, overcoming high costs, and improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention is further described below in conjunction with embodiment; The following embodiment is not for the limitation of the present invention, only as the mode of supporting the realization of the present invention, any equivalent structural replacement within the technical framework disclosed in the present invention, all is the present invention. the scope of protection of the invention;

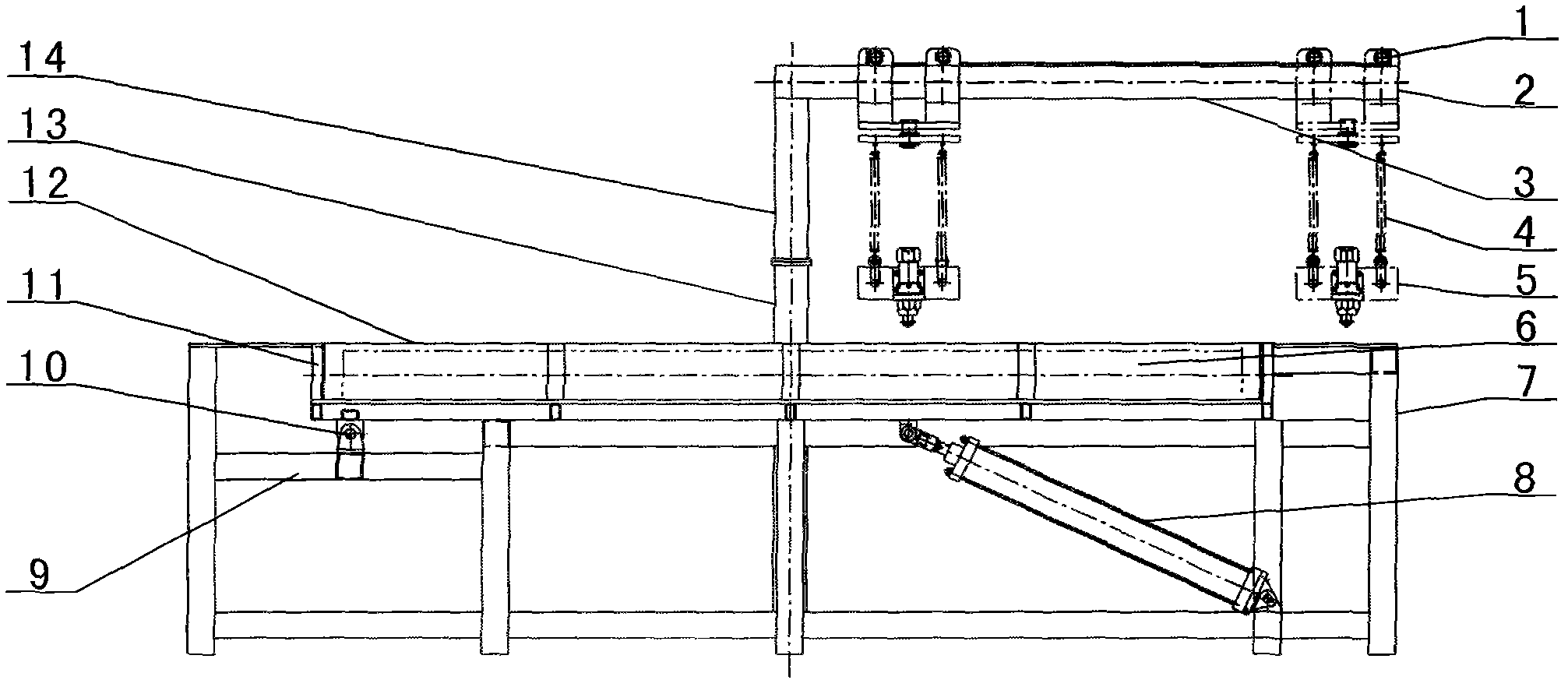

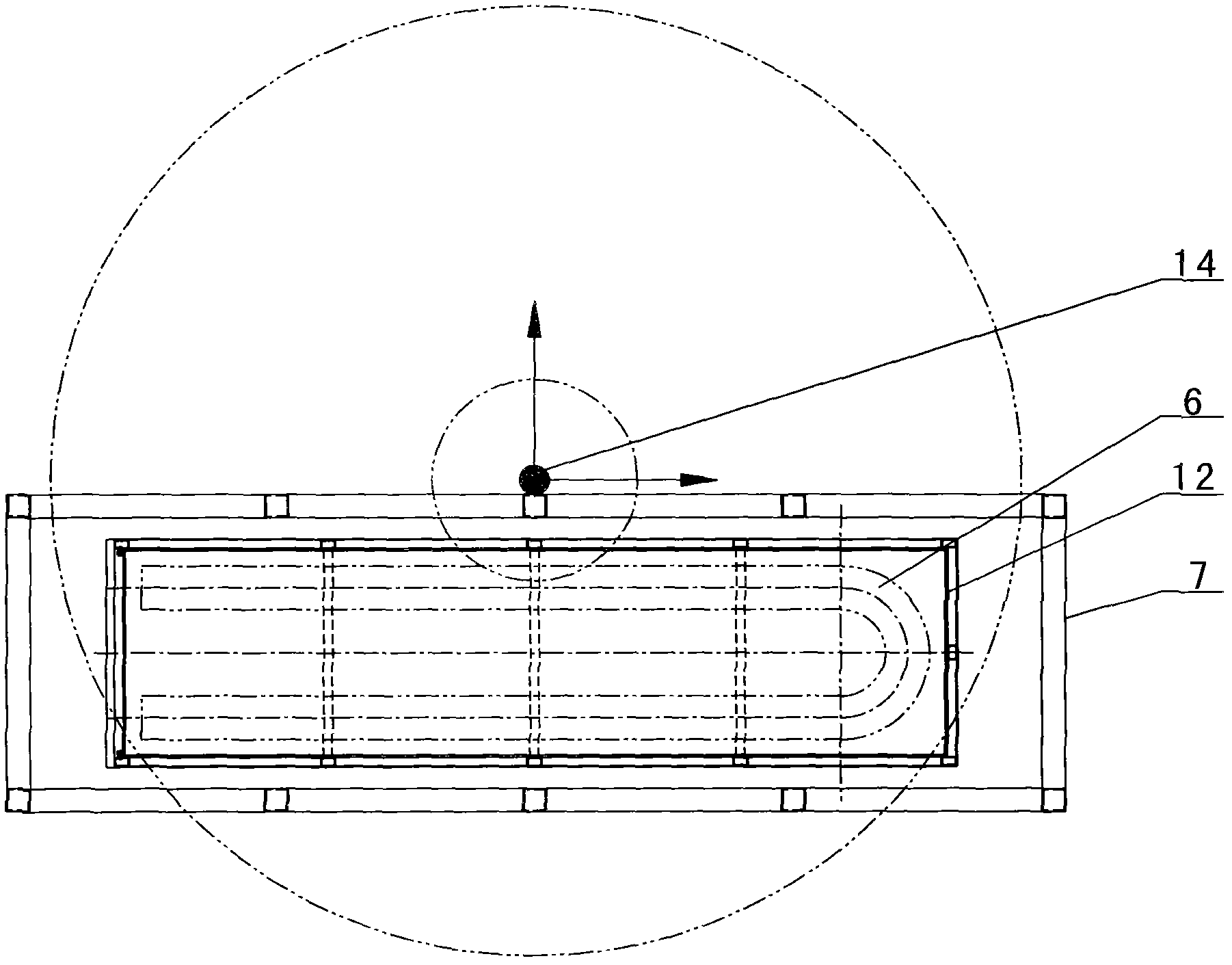

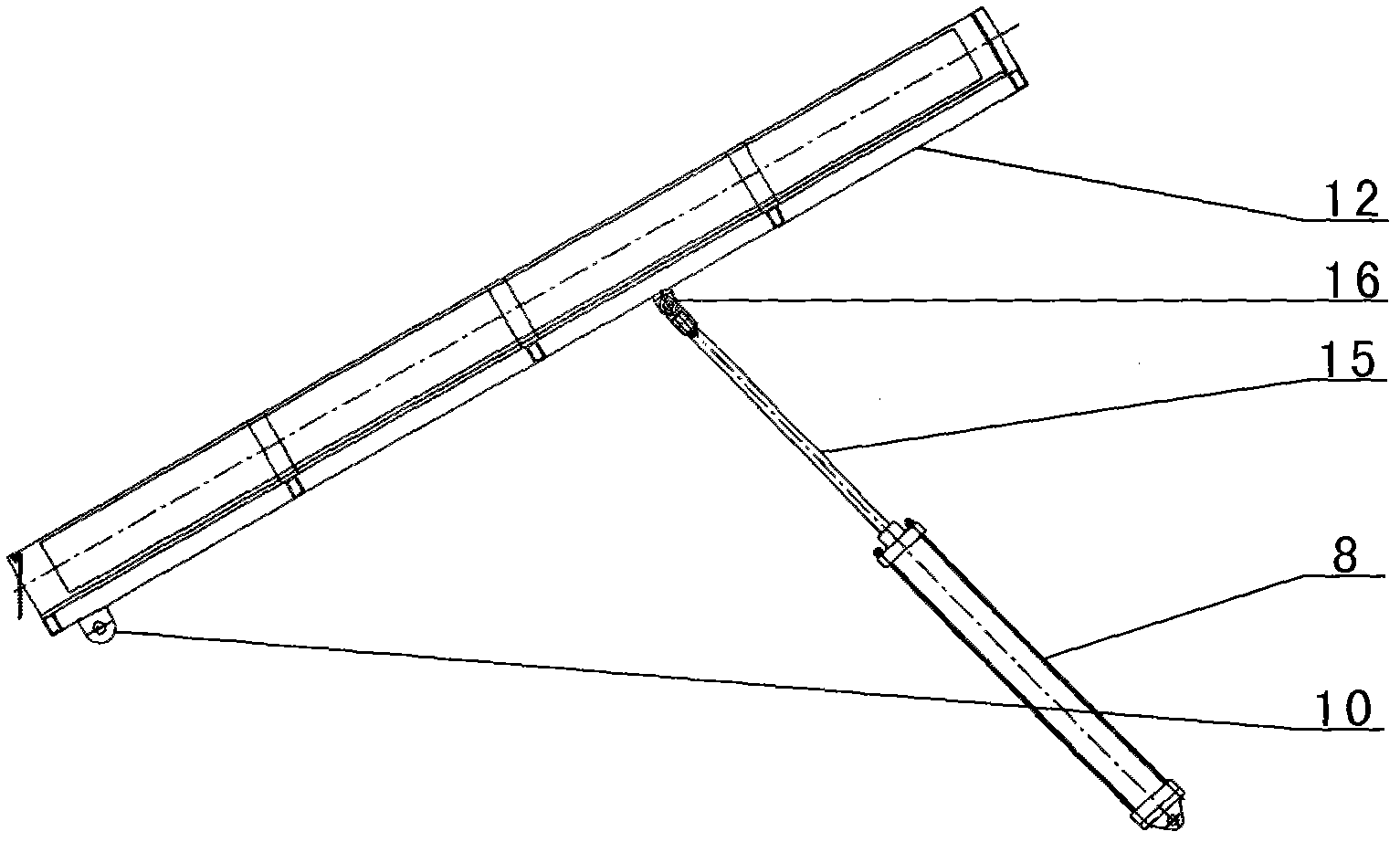

[0022] combined with figure 1 Or the polysilicon crushing device described in 2, including material box 12, column 13, rotating shaft 14, guide rail 3, sliding mechanism, elastic body, columbia model 98 impact cylinder 17 and tungsten-titanium alloy HRC70-80 impact head 18, in the material There is a column 13 in the middle of any side of the box 12, and the rotating shaft 14 is movably connected to the upper part of the column 13. One end of the guide rail 3 is fixedly connected with the upper end of the rotating shaft 14 or one end of the guide rail 3 is flexibly co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com