Power assembly for electric automobile

A technology of electric vehicles and powertrains, applied in the field of powertrains, can solve problems such as difficulty in driving motors, reduction of driving range, waste of battery energy, etc., to improve market competitiveness, reduce impact, and improve shift quality Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] Specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

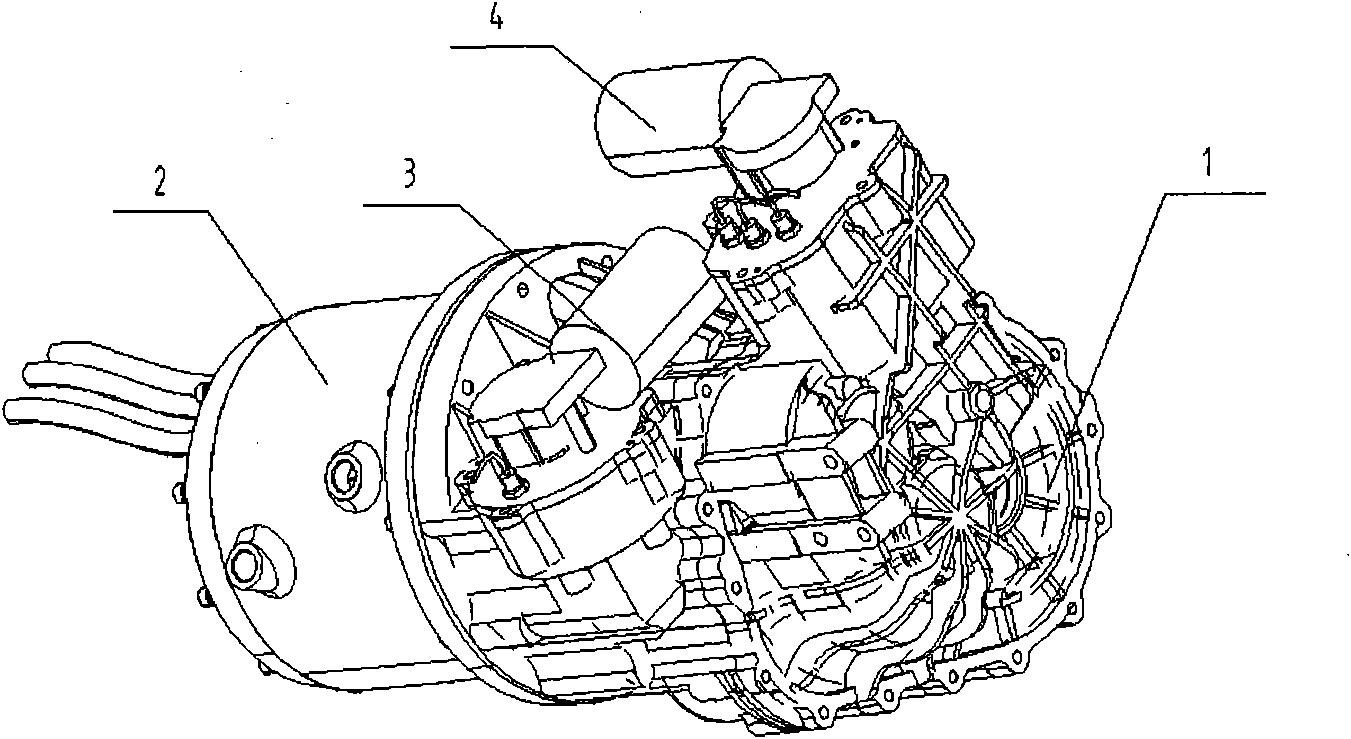

[0020] The electric vehicle power assembly includes two parts: a driving motor (2) and a power transmission system (1).

[0021] The drive motor (2) is a permanent magnet synchronous motor.

[0022] The power transmission system (1) includes a gear transmission system, an automatic shift system and an automatic parking system.

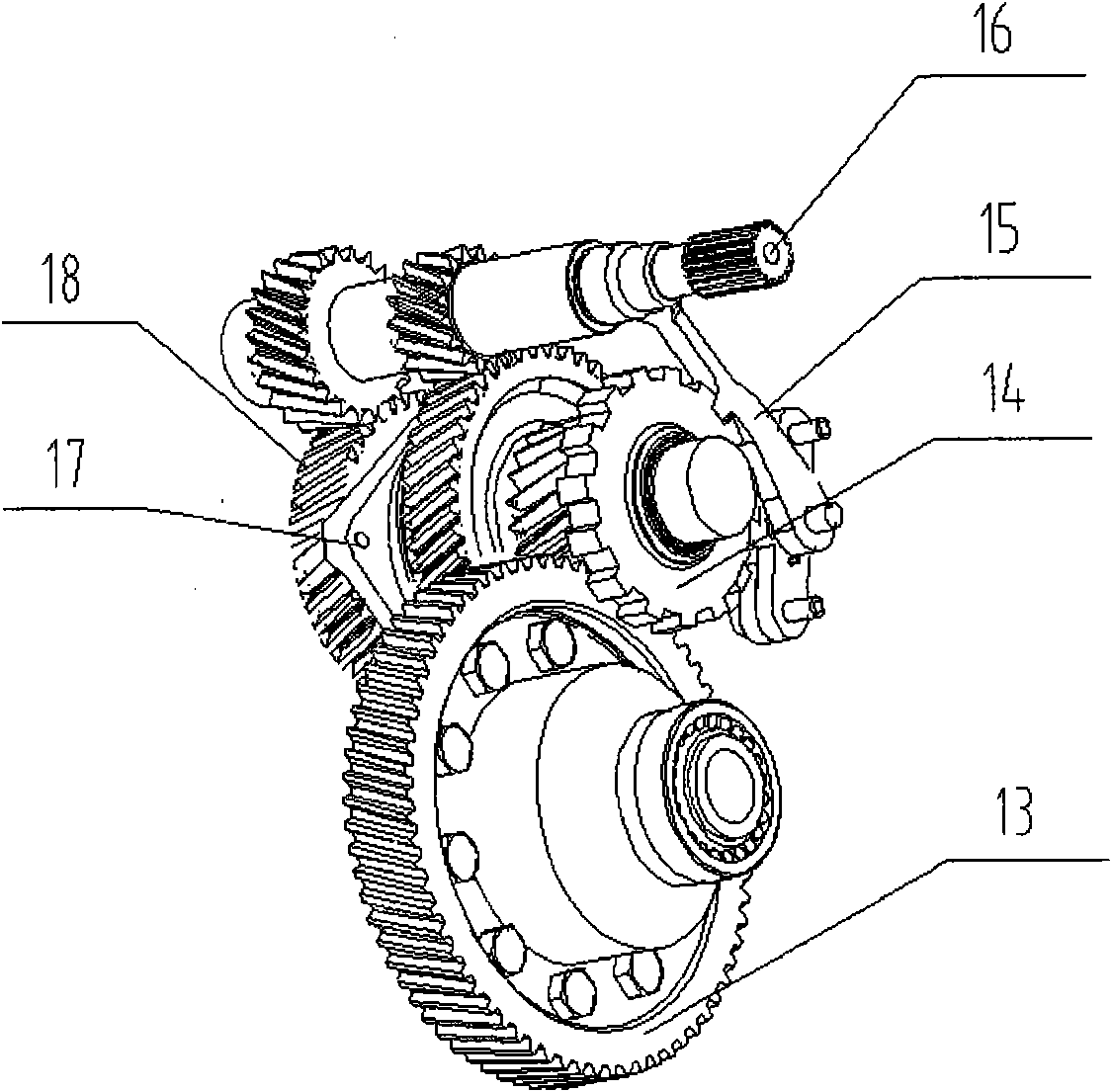

[0023] The gear transmission system includes a differential assembly (13), an input shaft (16), a shift fork and a synchronizer (17), a first gear and a second gear (18).

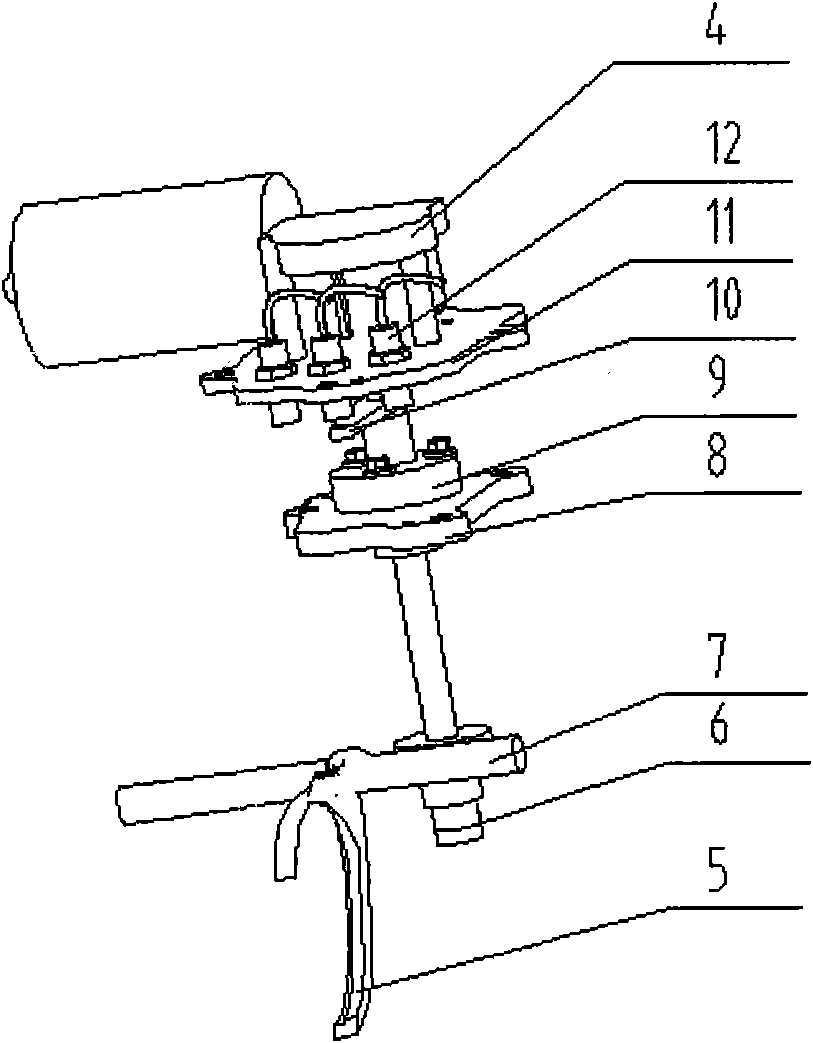

[0024] The automatic shift system includes a shift motor (4), a shift fork (5), a shift fork shaft (7), a shift shaft (6), a shift cover (8), a shift shaft angle sensor (9) , Shift position detection lever (10), shift motor cover (11), gear sensor (12).

[0025] The automatic parking system includes a P gear motor (3), a P gear pawl (15), a P gea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com