Rotary kiln and technique for processing composition brass or block shaped raw copper

A rotary furnace and miscellaneous copper technology, applied in the direction of rotary drum furnace, process efficiency improvement, furnace, etc., can solve the problems of manual operation safety hazards, low redox efficiency, and low degree of automation, so as to improve utilization rate and reduce black Smoke generation, the effect of avoiding personal safety accidents

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

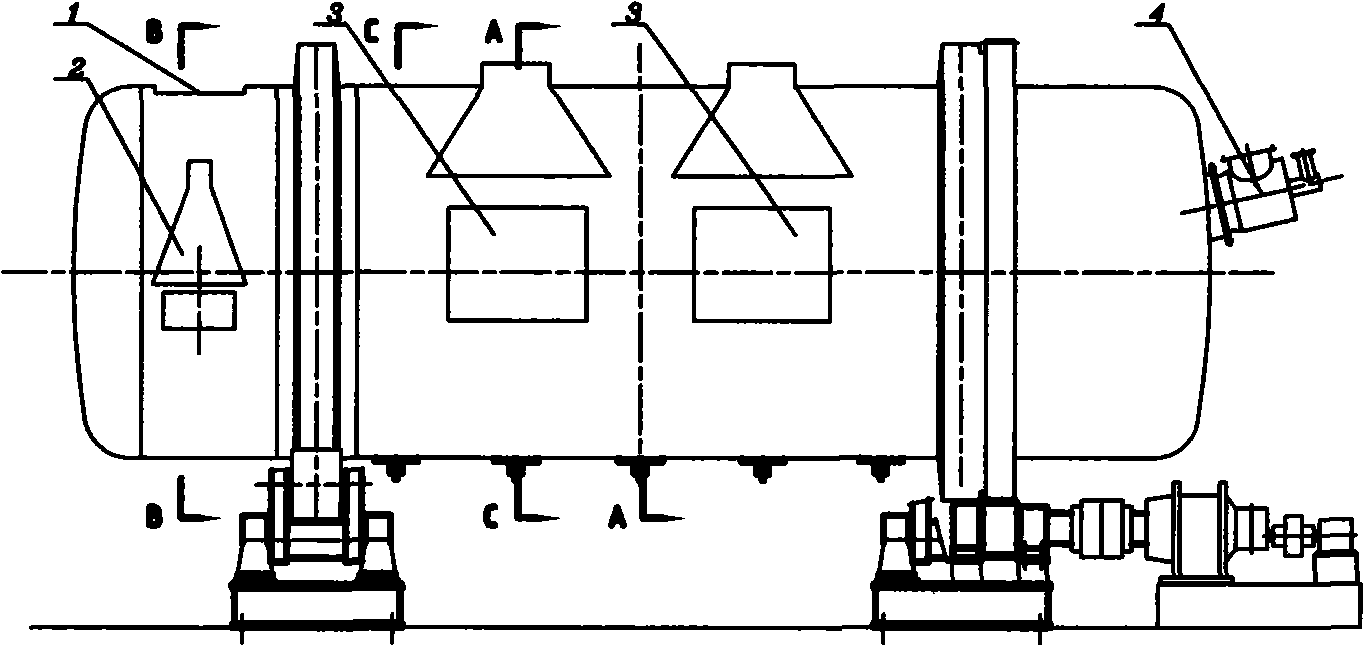

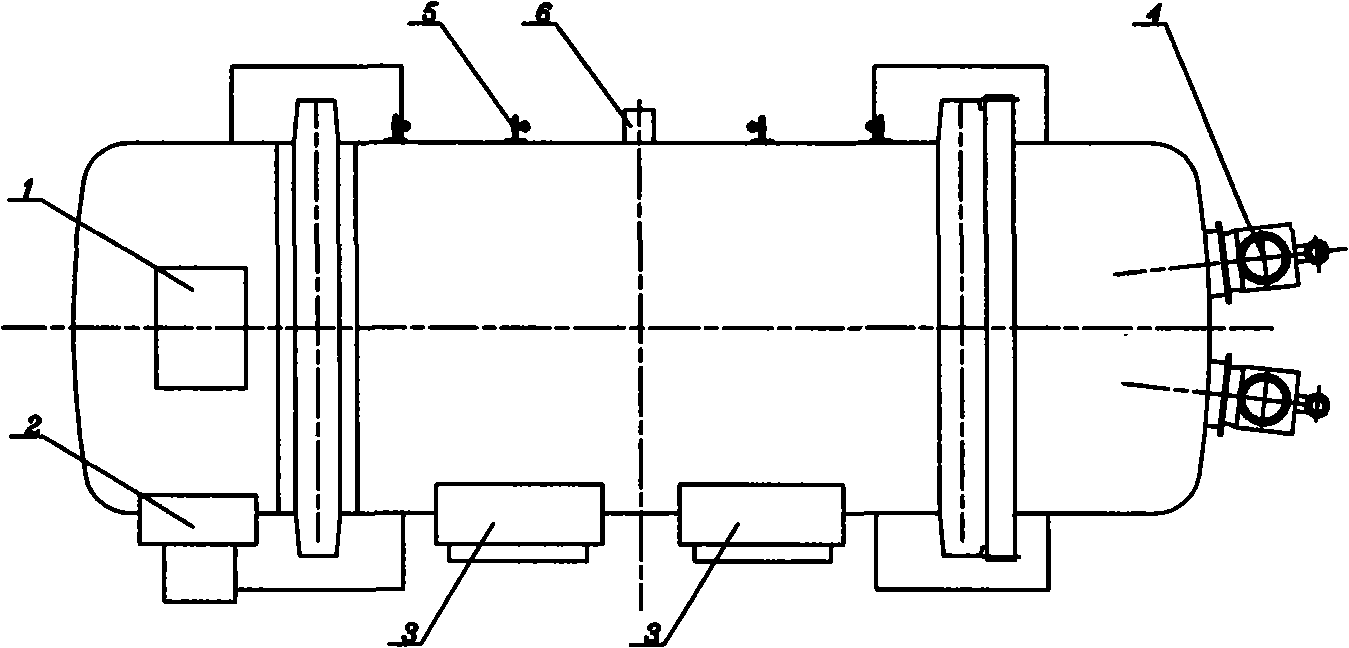

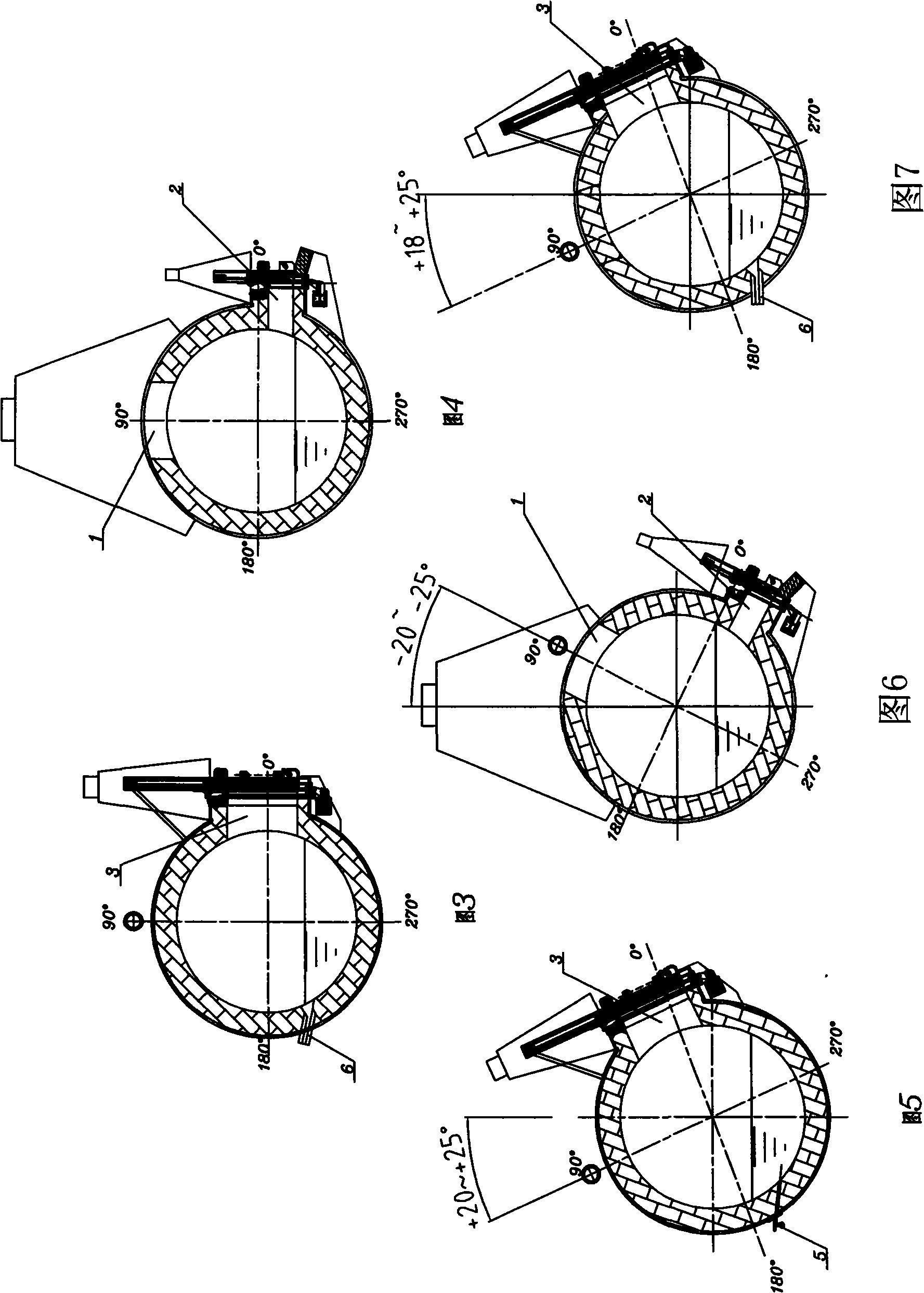

[0015] A rotary furnace, the rotary furnace is provided with 1-2 horizontal feeding ports 3; a slag outlet 2 is opened on the furnace body; a copper outlet 6 is equipped with an environmental fume cover; There are 1-2 holes 4 for installing burners on the end cover of the furnace body (according to the needs); on the other side of the end cover of the furnace body (where the burner holes are opened), there are vent holes for exhaust gas to be discharged radially 1 and equipped with an environmental fume hood; on the furnace body, there are several (according to needs) redox ports 5 that can be replaced quickly. There are two rolling rings on the furnace body, and the supporting wheels are used to support the bottom of the rolling rings, and the furnace body can rotate on the supporting wheels. The rollers are connected to the drive unit. The furnace body is lined with refractory materials, and the end cover of the furnace body is equipped with burners that can burn heavy oil,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com