Nb-Ti microalloying steel suitable for large line energy welding and smelting method therefor

A technology of high-energy welding and micro-alloyed steel, applied in welding medium, welding equipment, welding equipment, etc., can solve the problems of reducing the toughness of the base metal, weakening the effect of pinning grain boundaries, difficult to control production, etc., to achieve the production process. Simple, wide range of ingredients, good toughness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

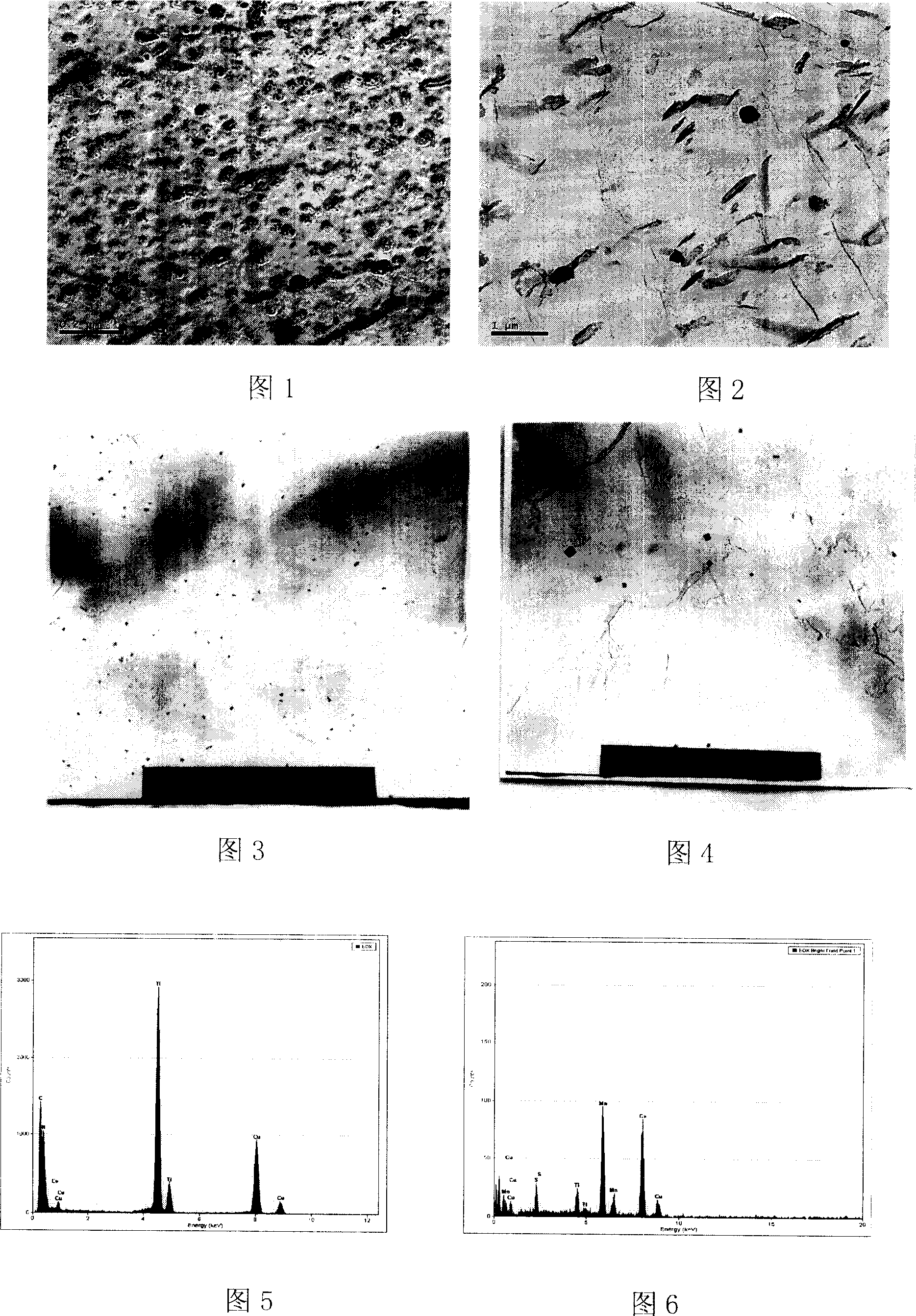

Image

Examples

Embodiment 1

[0028] Example 1, according to the composition requirements of the steel of the present invention, two furnaces of container steel were smelted. According to the requirements of Rel ≥ 490MPa container steel, the composition is selected as low C, high Mn series, and Mo, V, Ni alloys are added at the same time. The smelting process is LD+LF+VD, LF treatment is 20 minutes, VD treatment is 15 minutes, and the composition of VD is fine-tuned, adding Ti iron and Nb iron. This is followed by two-stage controlled rolling and accelerated cooling. Rolled into 24mm steel plate, 60KJ / cm, 90KJ / cm, 120KJ / cm welding tests were carried out. In addition, traditional steel plates produced by the same rolling process with different chemical components were subjected to welding tests of the same system, so as to compare the adaptability of the steel produced by the present invention and the traditional steel plate to high heat input welding. The data are shown in Tables 1-3.

[0029] Table 1, ...

Embodiment 2

[0036]Example 2, two furnaces of atmospheric corrosion resistant steel were smelted, and the components all met the requirements of the present invention. The components are low C, high Si and low Mn series, and more Cr, Ni and Cu elements are added according to the requirements of corrosion resistance, and the contents are all within the scope of the present invention. The first furnace adopts the smelting process of the present invention, that is, LD+LF+RH, LF slagging and S removal, refining for 18 minutes, RH treatment for 25 minutes, adjusting the composition, and adding Ti and Nb in RH. The second furnace adopts LD+RH, without desulfurization process, RH treatment for 25 minutes, including adjustment of alloy elements such as Ti and Nb are all carried out in RH. After smelting, use ordinary hot rolling method to roll into 10mm steel plate, conduct welding tests of 50KJ / cm and 70KJ / cm, and compare the performance of welding heat affected zone of the two steel plates. See...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com