High-tenacity high-strength spring steel

A high-strength, spring steel technology, applied in the field of high-strength spring steel, can solve problems such as poor hydrogen embrittlement resistance, spring fracture failure, etc., and achieve high fatigue life and corrosion fatigue resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] The steel of the present invention of the ML1900 brand of smelting the following components is annealed after hot rolling and polished into silver bright steel of Φ15.8mm.

[0041] C0.39, Si1.75, Mn0.64, P≤0.006, S≤0.003, Cr0.73, Ni0.22, Cu0.23, V0.06, Ti0.049, and the rest are Fe and impurity elements.

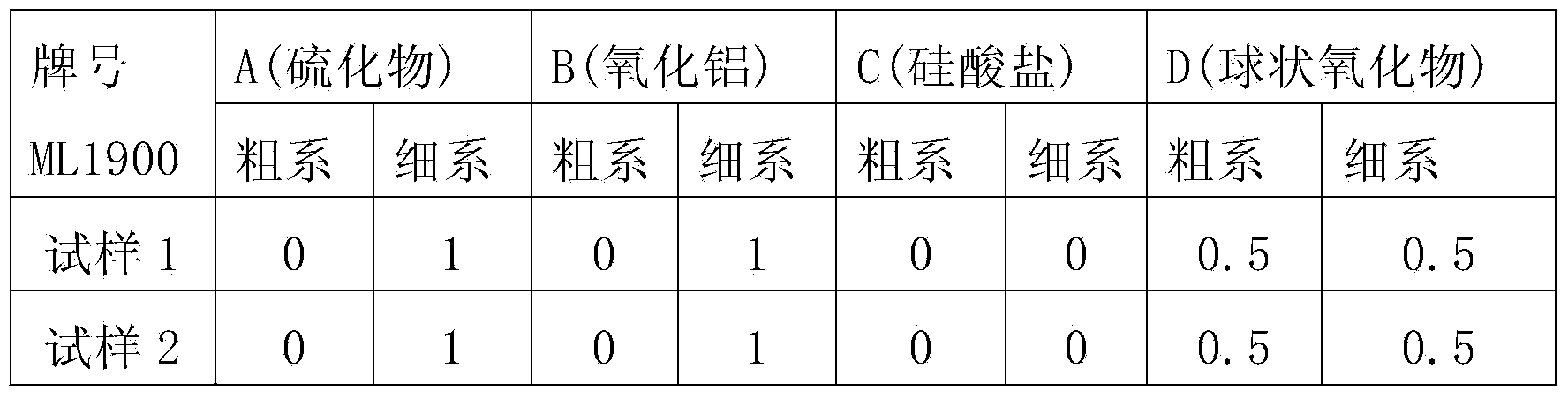

[0042] The test results of non-metallic inclusions in steel are as follows:

[0043]

[0044] The mechanical properties of the steel after heat treatment are as follows:

[0045]

[0046] Note: The heat treatment process of the sample: quenching temperature 890 ℃ heat preservation 30min oil quenching, 300 ℃ tempering 150min water cooling.

[0047] The grain size of the annealed steel after hot rolling is 8.0-7.0. Grain size after heat treatment ≥ 8.0.

Embodiment 2

[0049] The steel of the present invention of the ML1900 brand of smelting the following components is annealed after hot rolling and polished into a silver bright steel of Φ14.0mm.

[0050] C0.35, Si2.05, Mn0.95, P≤0.020, S≤0.014, Cr0.56, Ni0.18, Cu0.10, V0.090, Ti0.035, and the rest are Fe and impurity elements.

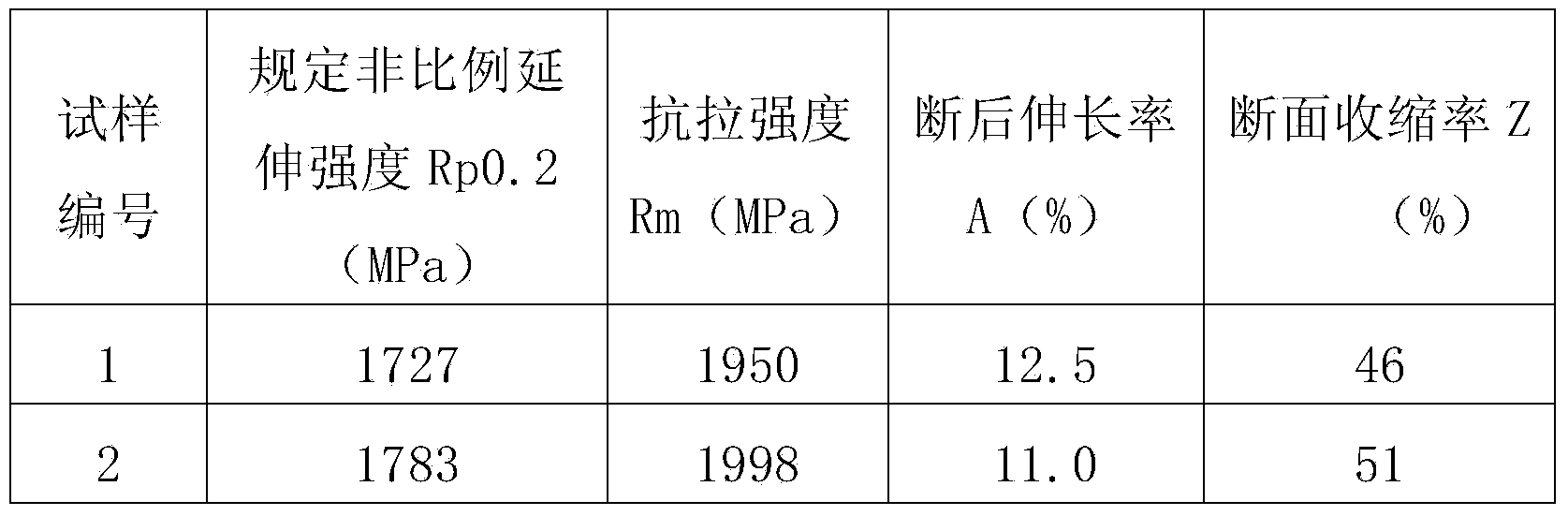

[0051] The test results of non-metallic inclusions in steel are as follows:

[0052]

[0053] The mechanical properties of the steel after heat treatment are as follows:

[0054]

[0055] Note: The heat treatment process of the sample: quenching temperature 900 ℃ heat preservation 30min oil quenching, 320 ℃ tempering 150min water cooling.

[0056] The grain size of the annealed steel after hot rolling is 8.0-7.0. Grain size after heat treatment ≥ 8.0.

Embodiment 3

[0058] The steel of the present invention of the ML1900 brand of smelting the following components is annealed after hot rolling and polished into silver bright steel of Φ16.8mm.

[0059] C0.48, Si1.89, Mn0.95, P≤0.010, S≤0.005, Cr0.80, Ni0.45, Cu0.28, V0.045, Ti0.089, and the rest are Fe and impurity elements.

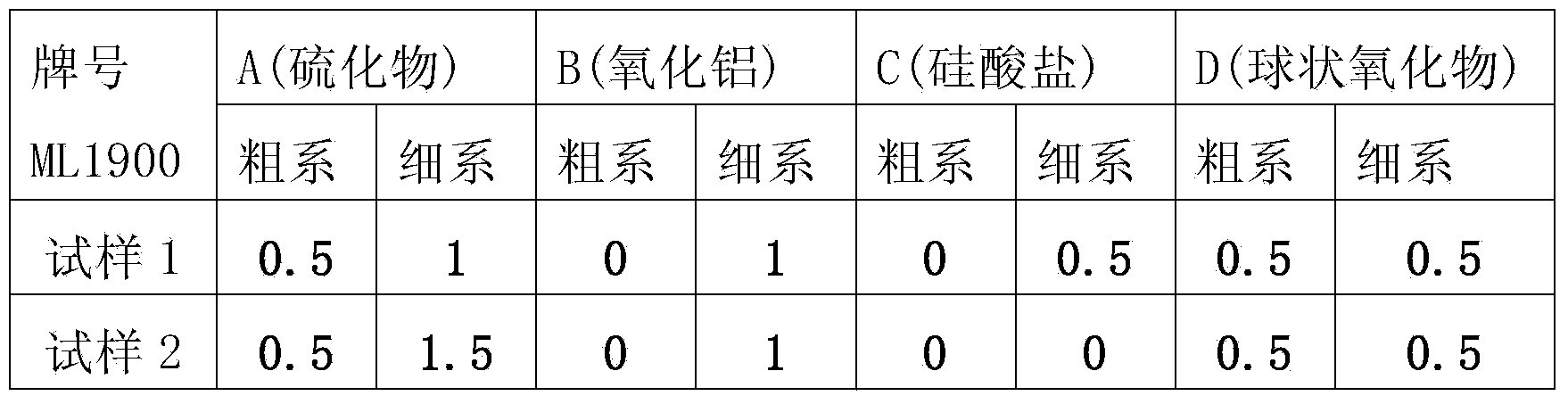

[0060] The test results of non-metallic inclusions in steel are as follows:

[0061]

[0062] The mechanical properties of the steel after heat treatment are as follows:

[0063]

[0064] Note: The heat treatment process of the sample: quenching temperature 890 ° C for 30 min oil quenching, tempering at 330 ° C for 150 min water cooling.

[0065] The grain size of the annealed steel after hot rolling is 8.0-7.0. Grain size after heat treatment ≥ 8.0.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com