35MnB steel and preparation method thereof

A technology for molten steel and target control, which is applied in the field of crawler chain rail links, 35MnB steel and its preparation, can solve the problems of poor controllability, increased nitrogen fixation cost and difficulty, and increased energy consumption cost of 35MnB steel.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

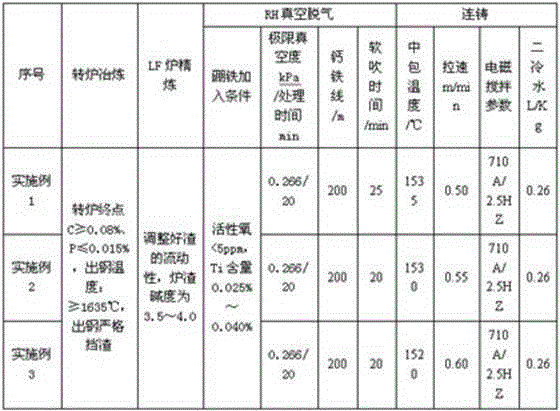

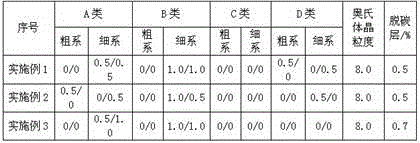

[0020] Within the scope of the chemical composition of the present invention, determine the chemical composition (wt%) of Examples 1, 2, and 3 as shown in Table 1, and the smelting and continuous casting steps and control parameters of Examples 1, 2, and 3 are shown in Table 2 , The main heating and rolling control parameters of Examples 1, 2, and 3 are shown in Table 3, and the microstructure and properties of the prepared 35MnB steel are shown in Table 4, Table 5, and Table 6.

[0021]

[0022] finished product ingredients C Si mn P S Cr Cu B Al Ti O / ppm N / ppm Example 1 0.35 0.25 1.31 0.013 0.001 0.22 0.03 0.0030 0.018 0.036 11 32 Example 2 0.35 0.25 1.29 0.01 0.002 0.22 0.04 0.0020 0.019 0.034 6 27 Example 3 0.34 0.26 1.32 0.011 0.001 0.23 0.04 0.0018 0.020 0.036 7 27

[0023] Table 2 Smelting and continuous casting system

[0024]

[0025] serial number Temperature of soaking...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com