Novel high-energy igniter charge and its coating technology

A kind of ignition powder, high-energy technology, applied in the direction of explosives, alkali metal compositions, etc., can solve the problems of unstable combustion speed, large amount of ignition powder, large occupied area, etc., and achieves easy operation, large ignition surface, and improved safety. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

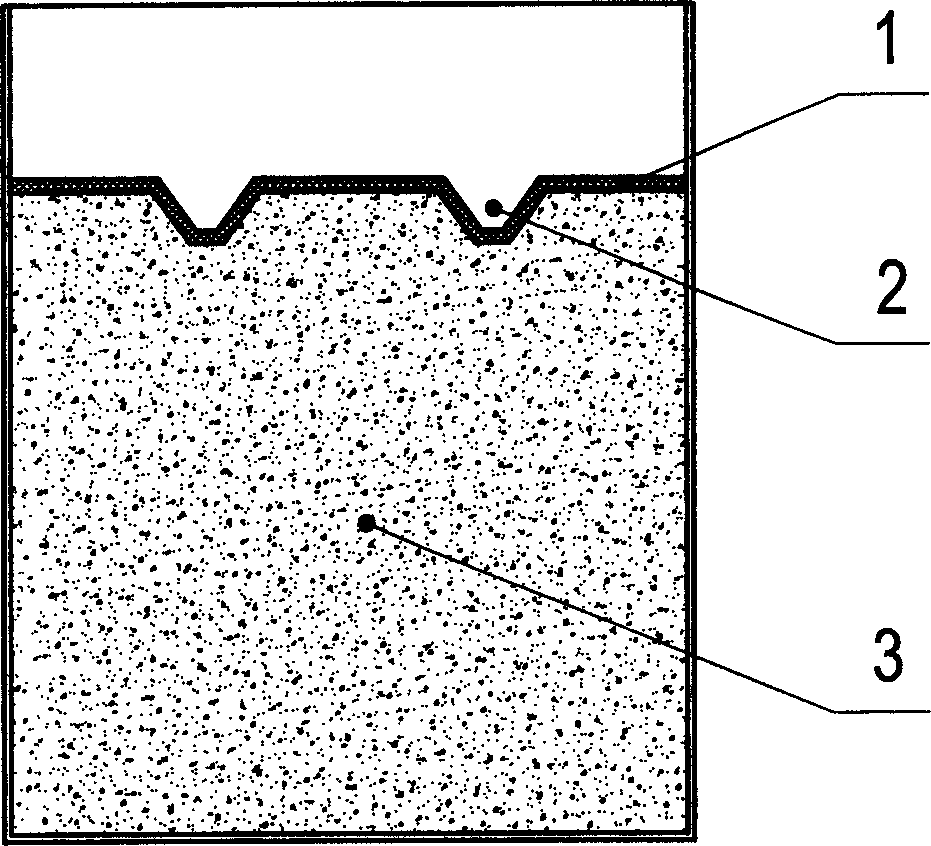

[0021] With reference to accompanying drawing, specific embodiment of the present invention is: under normal temperature and pressure, selects under the 100 mesh sieves of particle size, and purity is ten groups (55%, 58%, 60% in the potassium perchlorate weight ratio 55-75% of 98%) . Ten groups (45%, 42%, 40%, 38%, 36%, 35%, 33%, 30%, 38%, 25%) correspond to each other in 45%, and the sum of the weight ratios of each group is 100%. At room temperature and normal pressure, mix the above-mentioned ten groups of potassium perchlorate and fine spherical aluminum powder to form ten groups of solid materials, and set aside; then take the active energy binder solution weight ratio (addition) 2%, the active energy The proportion of components contained in the adhesive solution is: 30-40 grams of nitrocellulose is divided into ten groups (30 grams, 31 grams, 32 grams, 33 grams, 34 grams, 35 grams, 36 grams, 37 grams, 38 grams, 39 grams , 40 grams), respectively mixed with 1 liter of ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com