Automatic burr and foil dust brushing removing machine for aluminum foil

A technology of punching foil ash and aluminum foil hair, which is applied in the field of aluminum scrap and aluminum dust cleaning equipment, can solve the problems of lack of aluminum scrap and aluminum dust devices, etc., and achieve the effect of improving product quality, less air pollution, and good cleaning effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The structure of the present invention will be further described below in conjunction with the accompanying drawings and preferred specific embodiments of the present invention.

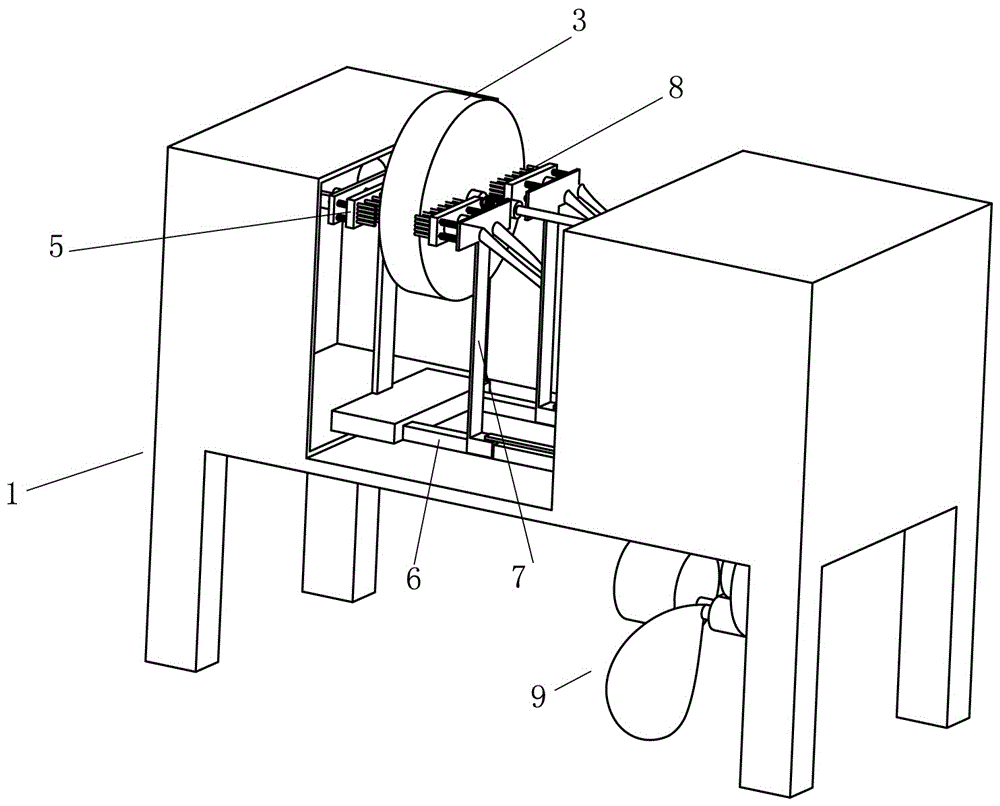

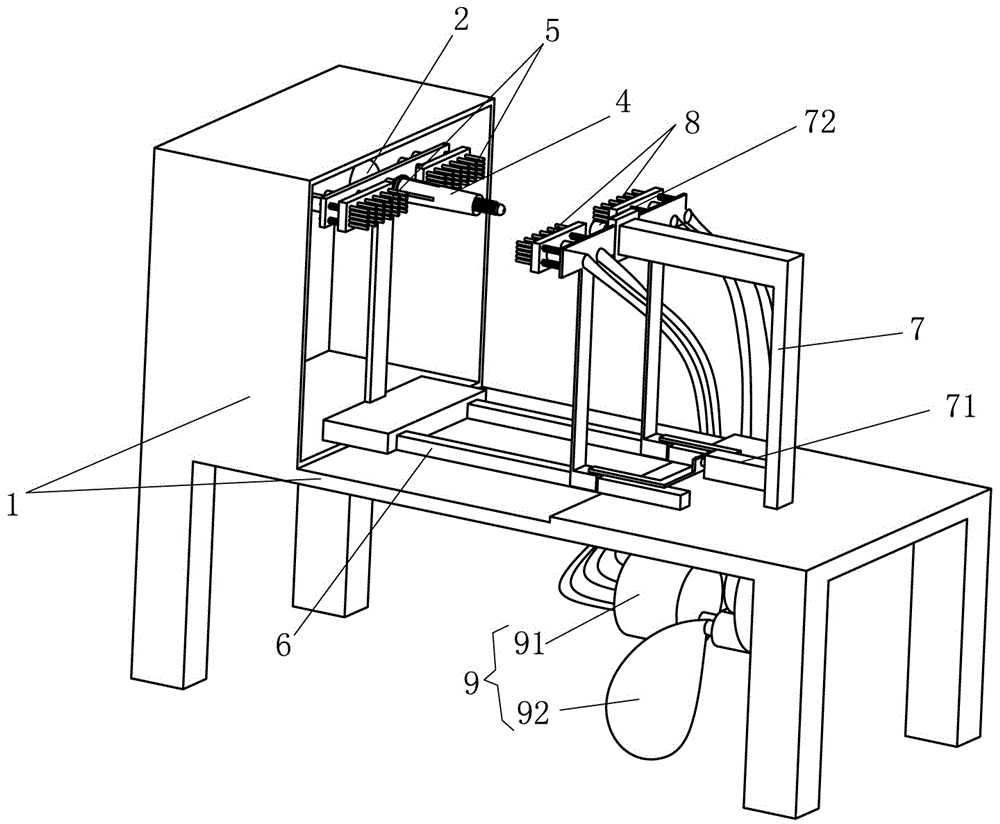

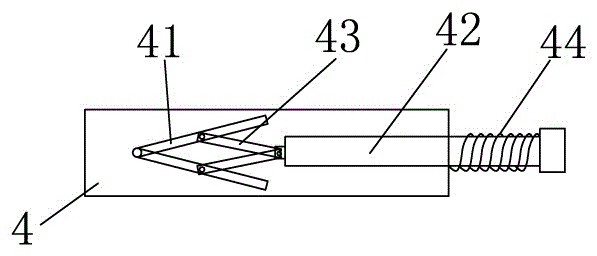

[0015] refer to Figure 1 to Figure 3 As shown in , the aluminum foil burr and foil dust automatic brushing machine of the present invention includes a frame 1, and the frame 1 is provided with an aluminum foil rotary drive motor 2, and the shaft of the aluminum foil rotary drive motor 2 is connected for the entire roll of aluminum foil 3 to be socketed. The hollow support shaft 4 is provided with the first brush 5 corresponding to the left end face of the aluminum foil sleeved on the hollow support shaft 4 on the frame 1, and the brush bracket 7 is slidably connected to the frame 1 through the slide rail 6 , the brush bracket 7 is provided with a second brush 8 corresponding to the right end face of the aluminum foil 3 sleeved on the hollow support shaft 4, and a driving second brush 8 is als...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com