Comprehensive processing and utilizing process of quadratic aluminum dust

A comprehensive treatment and secondary aluminum technology, applied in the direction of solid waste removal, transportation and packaging, separation of dispersed particles, etc., to achieve high-efficiency separation and recycling, realize safe production, and avoid potential safety hazards

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

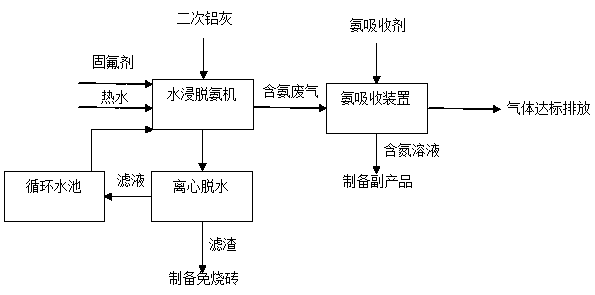

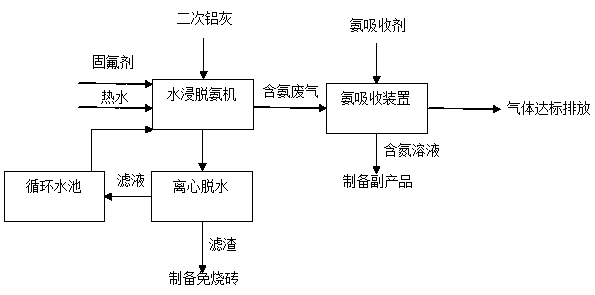

[0025] Please refer to figure 1 , a comprehensive treatment and utilization process of secondary aluminum ash of the present embodiment, the specific steps are as follows:

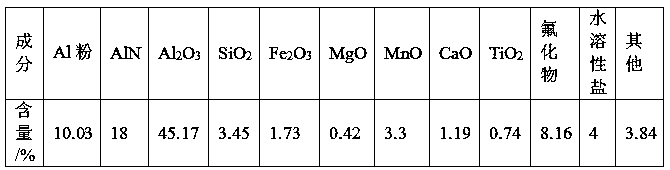

[0026] Deamination process: Add secondary aluminum ash (see Table 1 for specific composition) from an electrolytic aluminum enterprise into the water immersion deamination machine, and then pump 86°C hot water into the water immersion deamination machine with a sealed design, heat The amount of water and the amount of secondary aluminum ash are mixed according to the liquid-solid ratio of 3:1, and NaOH catalyst is added. The amount of catalyst is 4% of the amount of the secondary aluminum ash. The leaching time is 5h. After stirring, the ammonia-containing Exhaust gas, ammonia-containing waste gas escapes into the water immersion deamination machine, and then is collected to the ammonia absorption device through a closed pipeline. The ammonia gas removal rate reaches more than 90%; spray dilute sulfuric ac...

Embodiment 2

[0032] The main components of the secondary aluminum ash in Example 2 are 20% of aluminum nitride, 6% of aluminum powder, 57% of alumina, 5% of fluoride, and 12% of others.

[0033] Please refer to figure 1 , a comprehensive treatment and utilization process of secondary aluminum ash of the present embodiment, the specific steps are as follows:

[0034] Deamination process: Add the above-mentioned secondary aluminum ash to the water immersion deamination machine, and then pump 86°C hot water into the water immersion deamination machine with a sealed design. The amount of hot water and the amount of secondary aluminum ash are based on the liquid-solid ratio For 2:1 mixing, another NaOH catalyst is added, the amount of catalyst is 5% of the amount of the secondary aluminum ash, the leaching time is 5h, after stirring, the ammonia-containing waste gas escapes after the reaction, and the ammonia-containing waste gas escapes to water leaching for deamination In the machine, it is ...

Embodiment 3

[0038] The main components of the secondary aluminum ash in Example 3 are 30% of aluminum nitride, 12% of aluminum powder, 37% of alumina, 3% of fluoride, and 18% of others.

[0039] Please refer to figure 1 , a comprehensive treatment and utilization process of secondary aluminum ash of the present embodiment, the specific steps are as follows:

[0040] Deamination process: Add the above-mentioned secondary aluminum ash to the water immersion deamination machine, and then pump 86°C hot water into the water immersion deamination machine with a sealed design. The amount of hot water and the amount of secondary aluminum ash are based on the liquid-solid ratio For 4:1 mixing, another NaOH catalyst is added, the amount of catalyst is 5% of the amount of the secondary aluminum ash, the leaching time is 3h, after stirring, the ammonia-containing waste gas escapes after the reaction, and the ammonia-containing waste gas escapes to water leaching for deamination In the machine, it is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com