Low-temperature baked water-based electrosilvering paint and preparation method thereof

A technology of low-temperature baking and electroplating silver, which is applied in the direction of coating, etc., can solve the problems of silver powder alignment in water-based electrosilvering and high tension in the system, and achieve bright color, good alignment, excellent adhesion and solvent resistance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

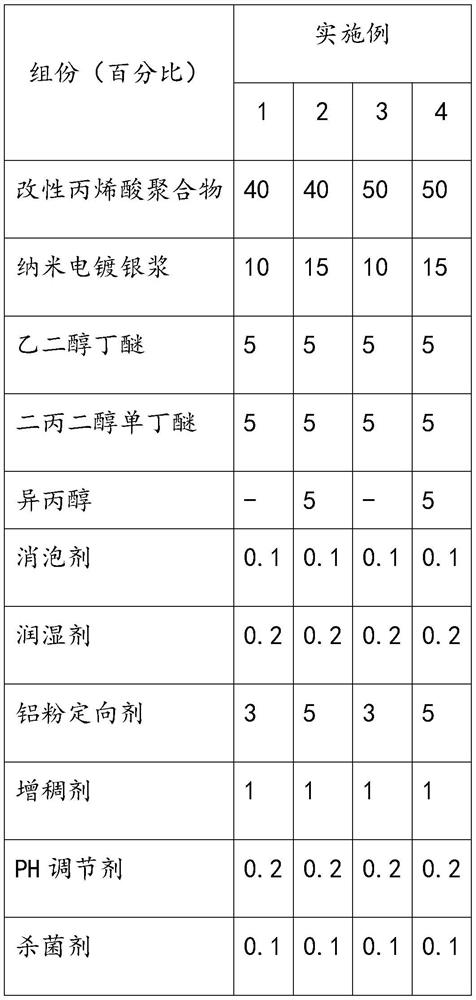

Embodiment 1

[0026] The components in Example 1 include the following mass ratio: 40% acrylic acid modified polymer, 10% nanometer silver plating paste, 5% ethylene glycol butyl ether, 5% dipropylene glycol monobutyl ether, 0.1% defoaming agent (composition is BYK-033), 0.2% wetting agent (composition is TEGO-810), 3% aluminum powder orientation agent (composition is KX-630), 0.2% PH regulator (composition is N, N-2 ethanolamine), 0.1% fungicide (including 1.0wt% 1,2-benzisothiazolin-3-one), 1% thickener.

Embodiment 2

[0028] Components in embodiment 2 include the following mass ratio: 40% acrylic acid modified polymer, 15% nanometer silver plating paste, 5% ethylene glycol butyl ether, 5% dipropylene glycol monobutyl ether, 5% isopropyl Alcohol, 0.1% defoamer (composition is BYK-033), 0.2% wetting agent (composition is TEGO-810), 5% aluminum powder orientation agent (composition is KX-630), 0.2% PH regulator (composition is N,N-2 methylethanolamine), 0.1% fungicide (including 1.0wt% 1,2-benzisothiazolin-3-one), 1% thickener.

Embodiment 3

[0030] Components in embodiment 3 include following mass ratio: 50% acrylic acid modified polymer, 10% nanometer electroplating silver paste, 5% ethylene glycol butyl ether (BCS), 5% dipropylene glycol monobutyl ether (DPNB ), 0.1% defoamer (BYK-033), 0.2% wetting agent (TEGO-810), 3% aluminum powder orientation agent (KX-630), 0.2% PH regulator (N, N-2 methyl ethanolamine ), 0.1% fungicide (1.0wt% 1,2-benzisothiazolin-3-one), 1% thickener.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com