Patents

Literature

69results about How to "Film thickness" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

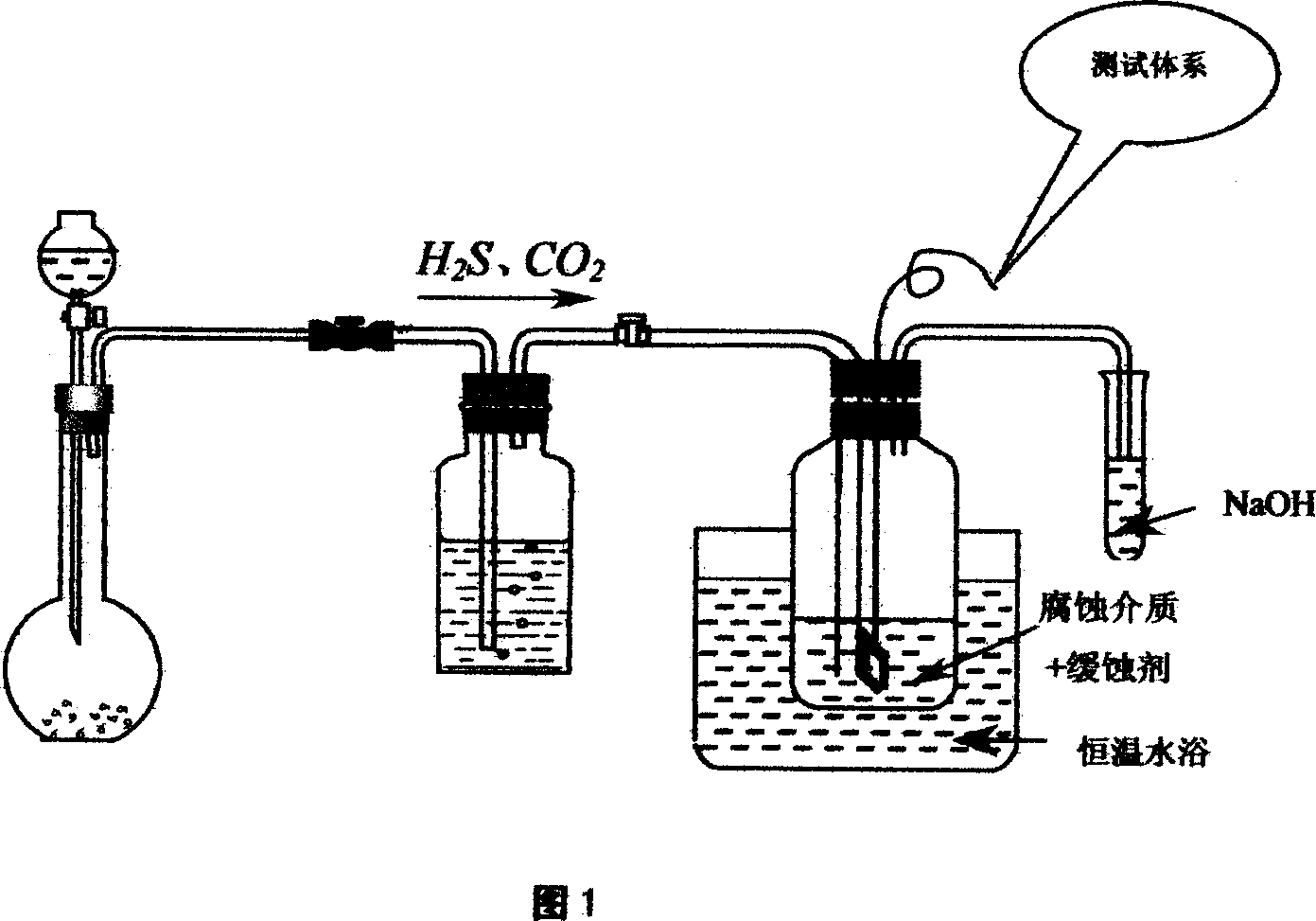

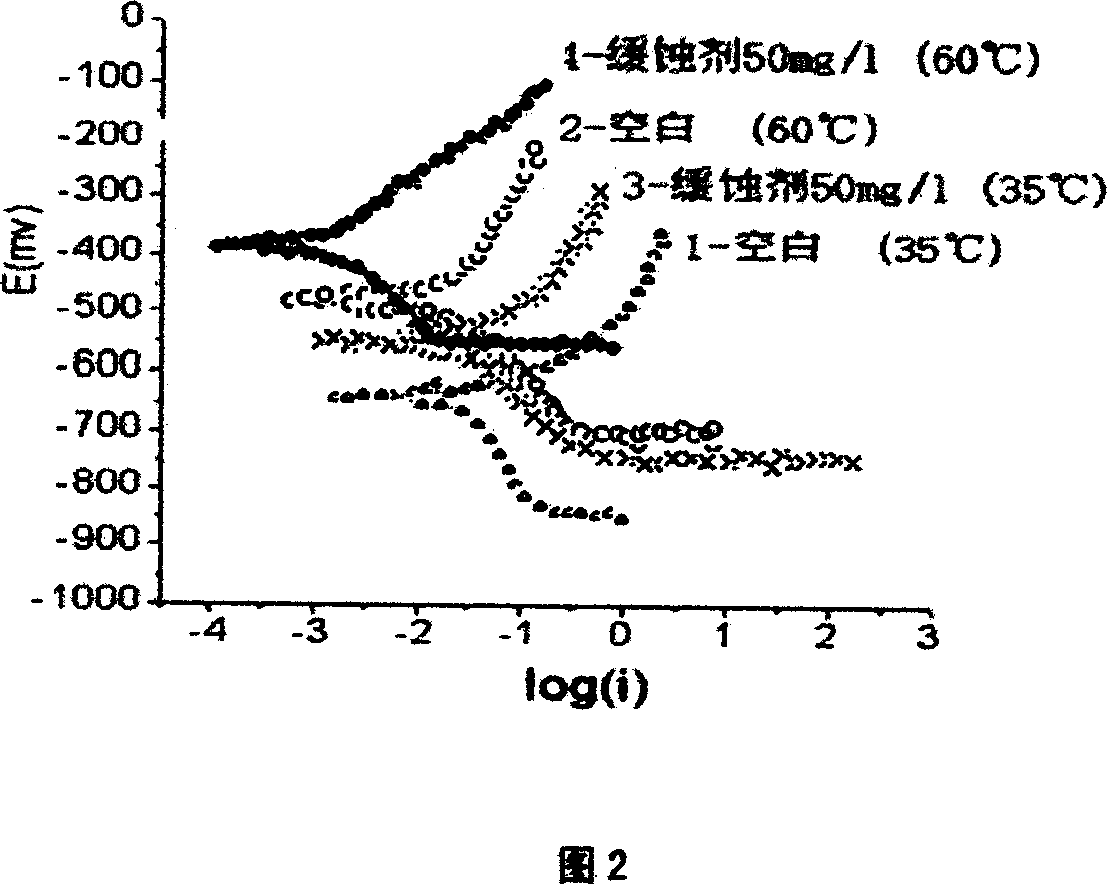

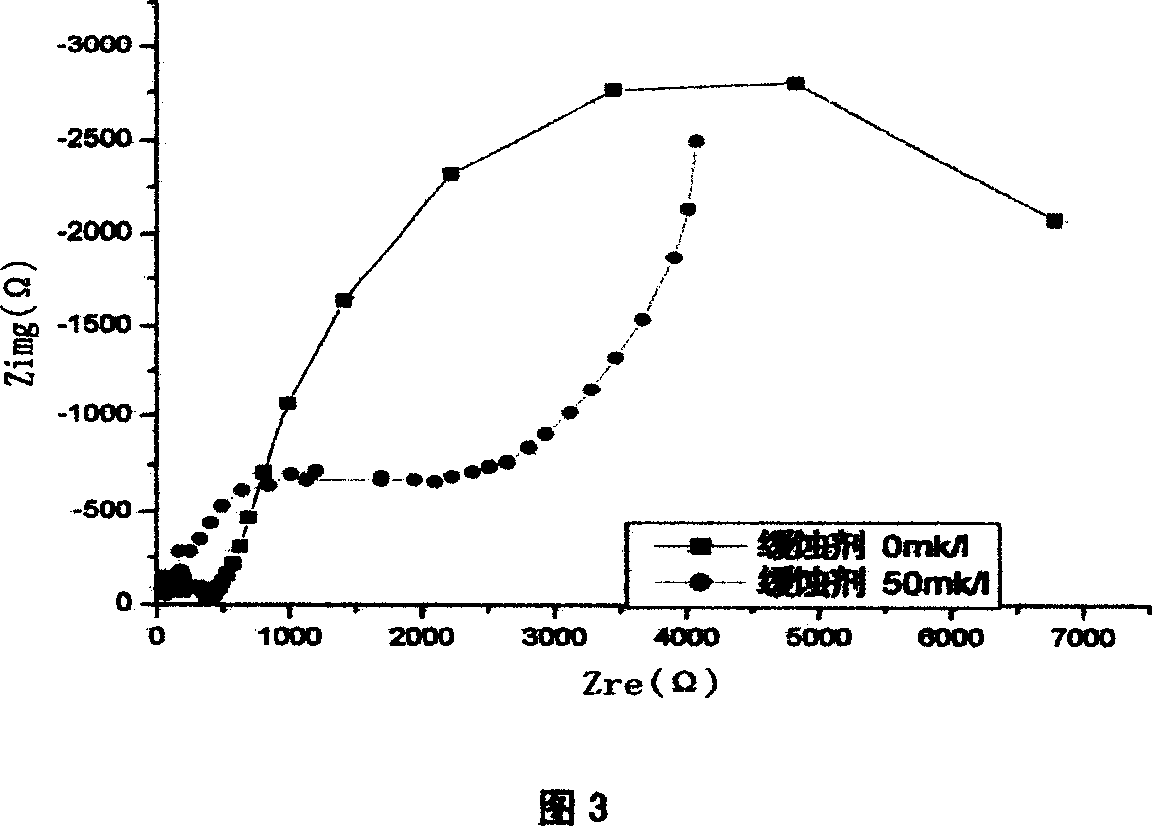

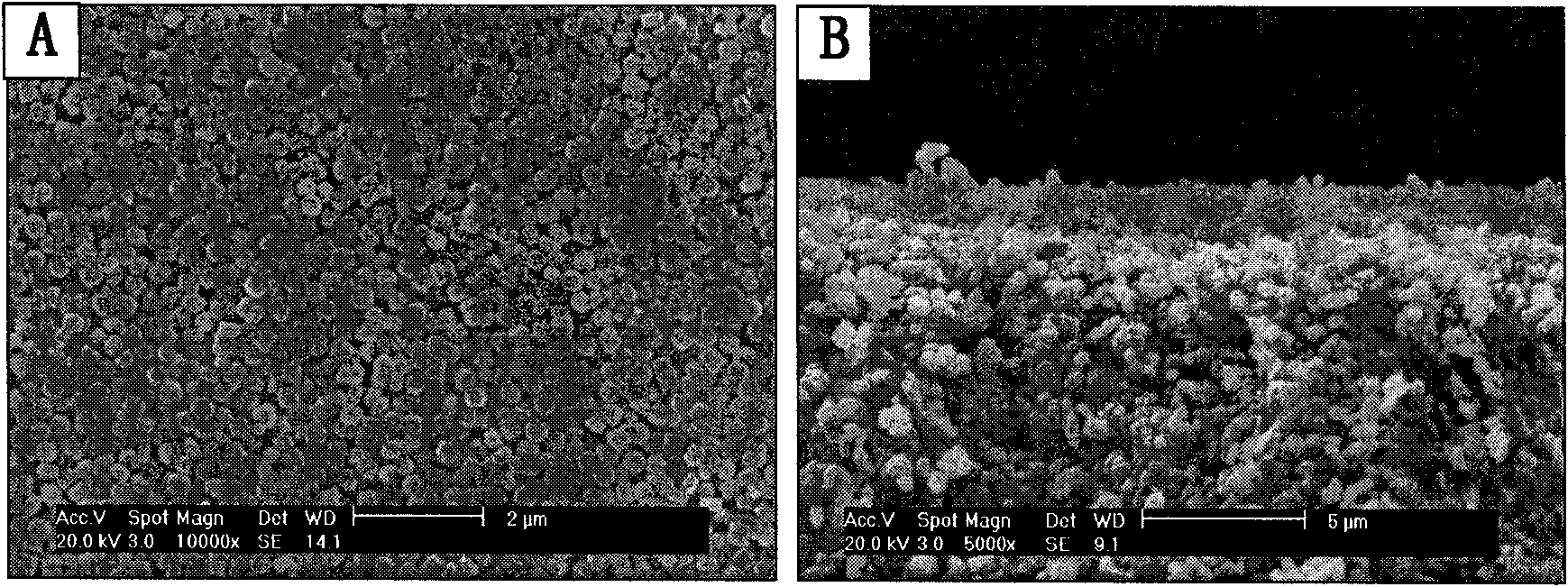

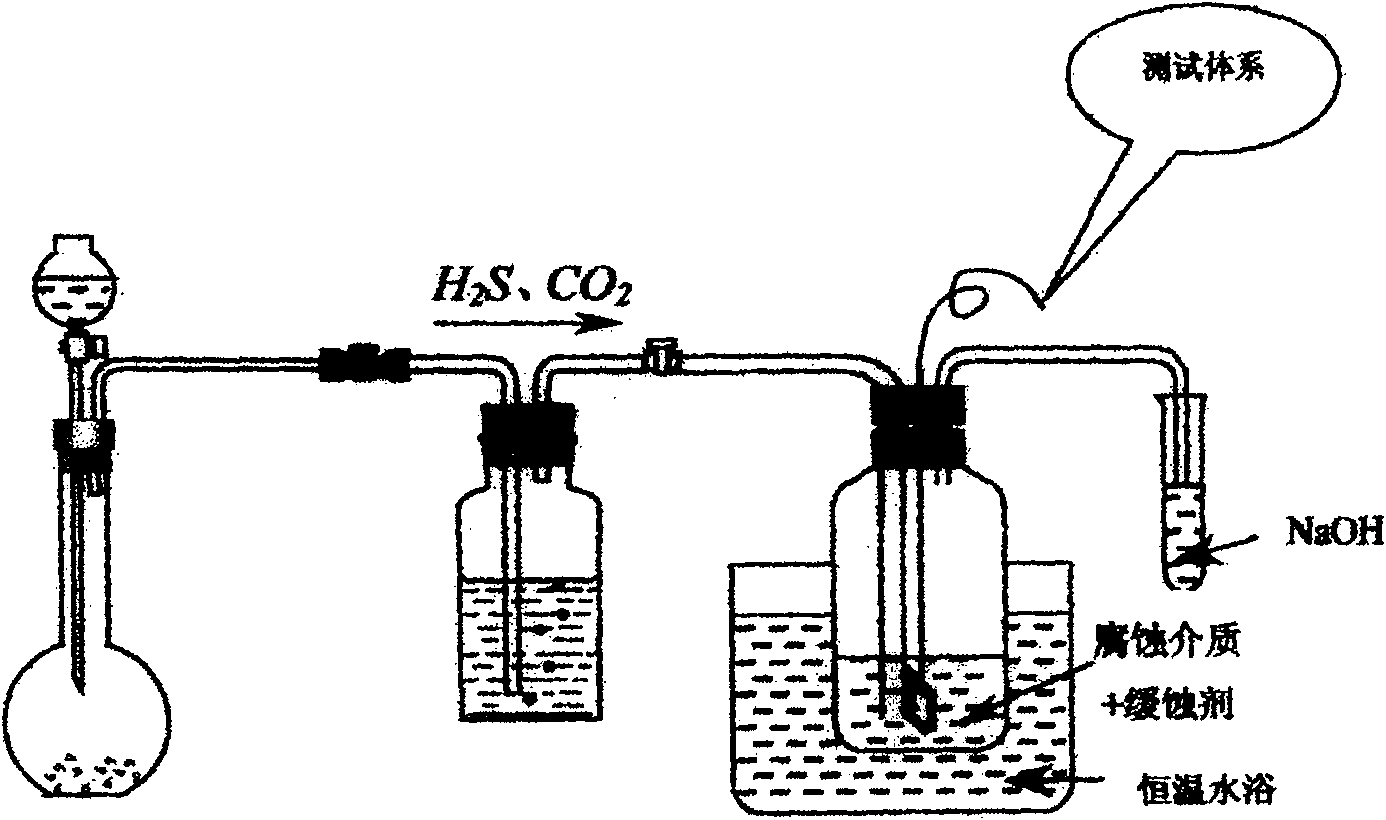

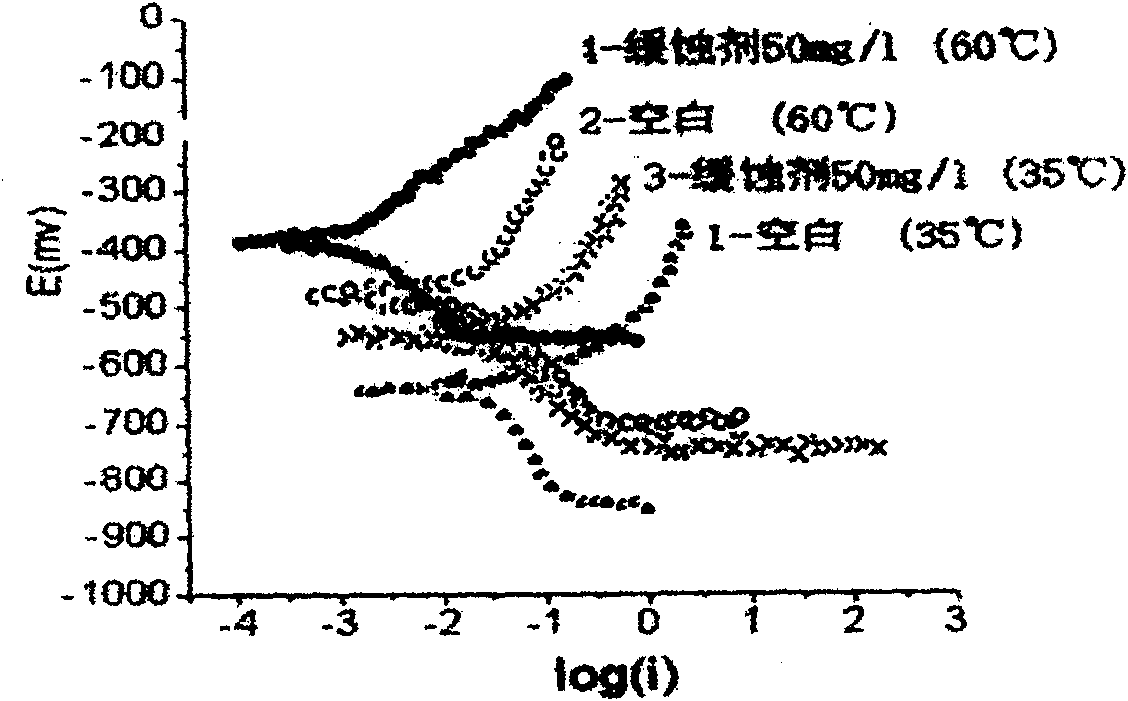

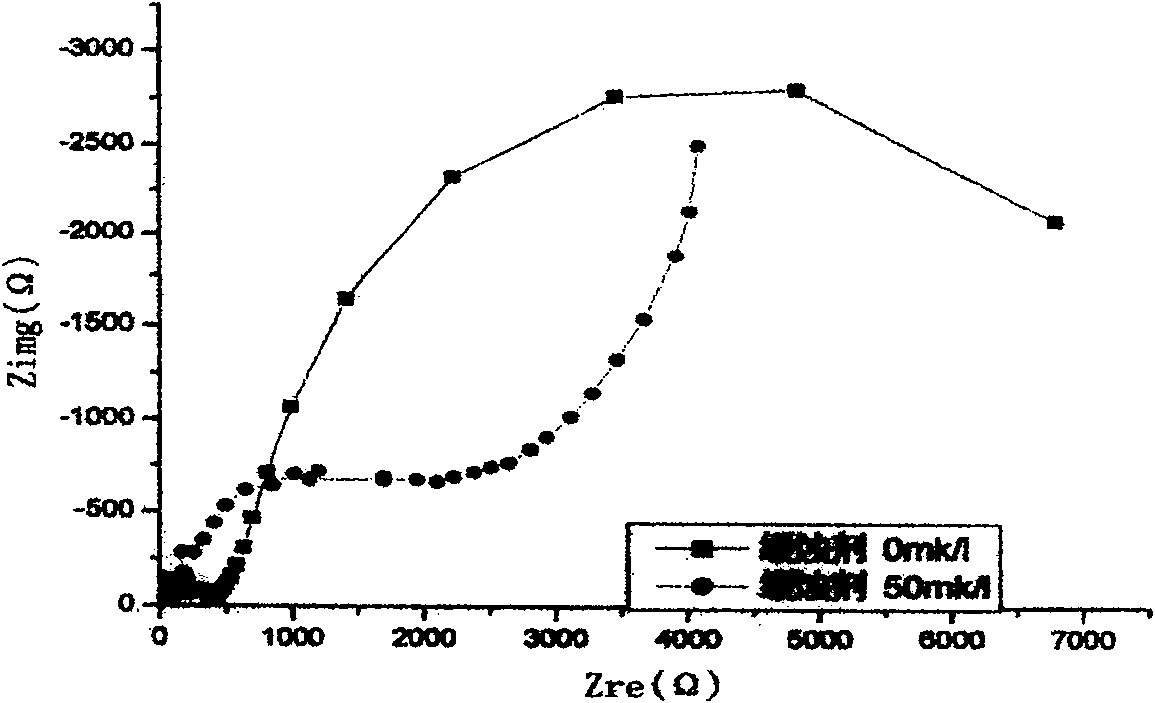

Corrosion inhibitor resistant to H2S and CO2

InactiveCN1966774ADoes not affect separation efficiencyGood corrosion inhibition effectBorehole/well accessoriesIsopropyl alcoholFatty alcohol

The invention relates the chemical engineering field, especially a H2 and CO2 inhibiter. H2 and CO2 are produced accompany to oil-gas field exploitation and transfusion process, and can corrode exploitation equipment. The inhibiter contains at least (by wt. %): isopropyl alcohol 10-30, fatty alcohol polyoxyethylene ether .1-0.5, and litol polyoxyethylene ether 0.1- 1.0. The inhibiter can be used in oil / water well with high temperature and pressure, and has the advantages of good corrosion resistance, low consumption, low cost and high efficiency.

Owner:CHINA NAT PETROLEUM CORP CHUANQING DRILLING ENG CO LTD

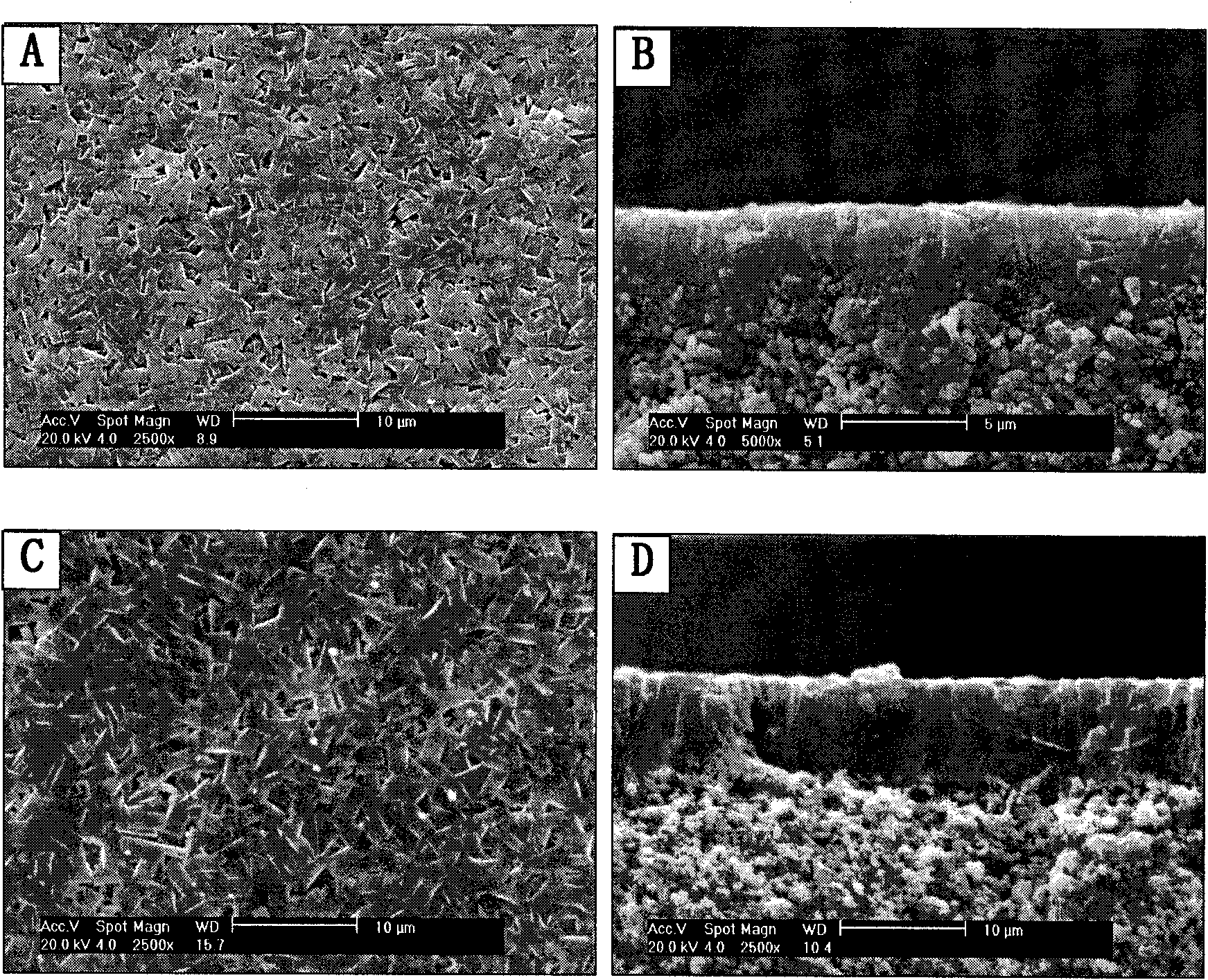

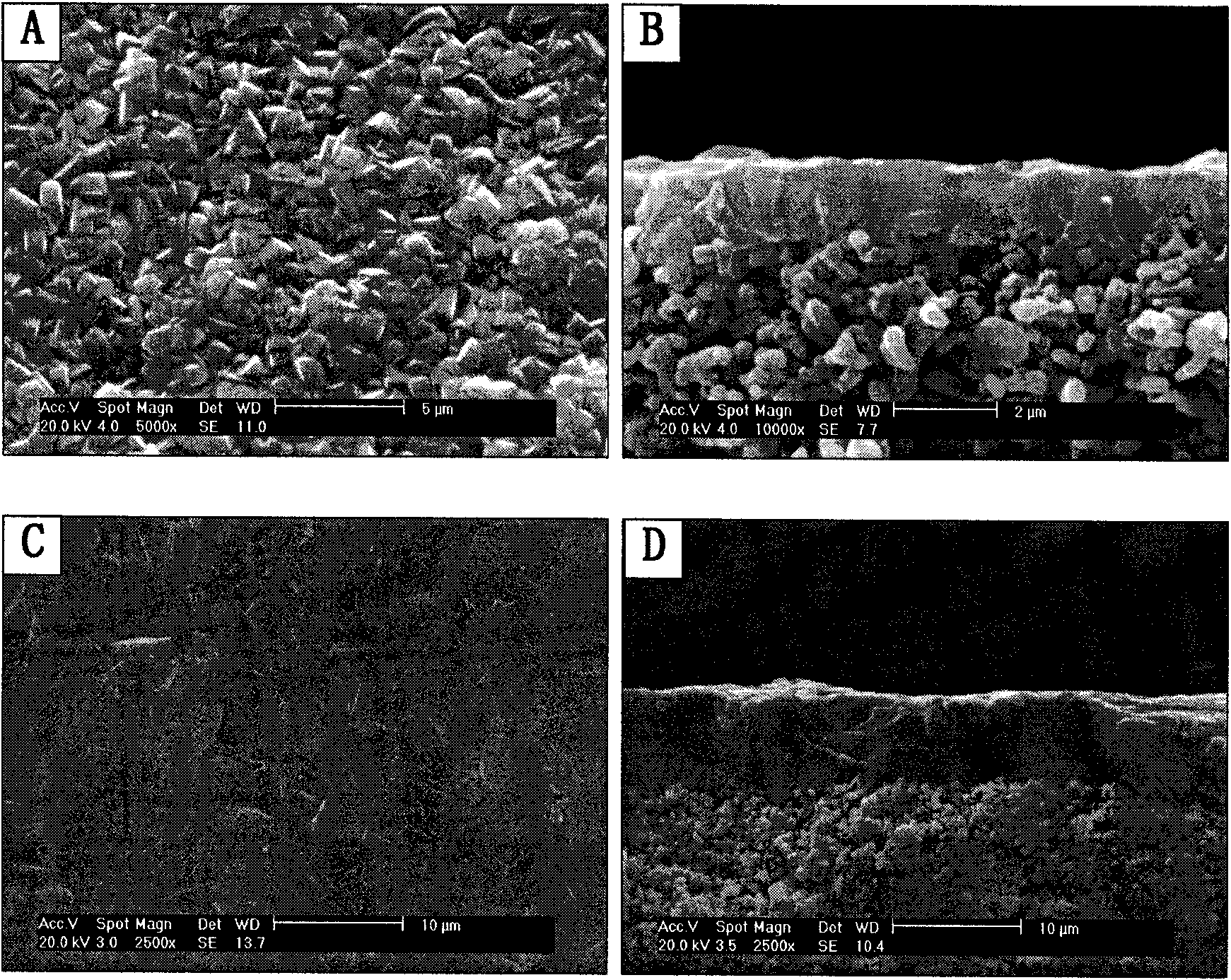

Preparation method for ZSM-5 molecular sieve membrane with high hydrophobicity

InactiveCN101941716APromotes in-plane directional growthIncrease water contentPentasil aluminosilicate zeoliteCarbon nanotubeHeteroatom

The invention relates to a preparation method for ZSM-5 molecular sieve membrane with high hydrophobicity, which comprises the following steps: (1) preparing a compact molecular sieve seed crystal layer; (2) putting a porous support with the molecular sieve seed crystal layer into a high pressure crystallized kettle, adding synthetic solutions, carrying out at least twice hydrothermal synthesis to promote full crosslinking growth between the molecular sieve seed crystals so as to finally form a complete molecular sieve membrane with orientation; and (3) adopting self catalysis property of heteroatom-containing ZSM-5 molecular sieve, adopting a hydrogenation deep catalytic cracking process to remove organic templates in the molecular sieve membrane under the lower temperature. The invention can effectively avoid the formation of intercrystalline defects of the molecular sieve membrane, also enables the cracked organic templates to form a single-walled carbon nano tube in the pore canal of the molecular sieve membrane, increases the hydrophobicity of the molecular sieve membrane, has mild process condition, simpler operation, lower cost and wide applicability, is not only suitable for planning production of the molecular sieve membrane, but also is benefit for the industrialization of the membrane separation technique with lower energy consumption of organic matter aqueous solution with low concentration.

Owner:GUANGZHOU INST OF ENERGY CONVERSION - CHINESE ACAD OF SCI

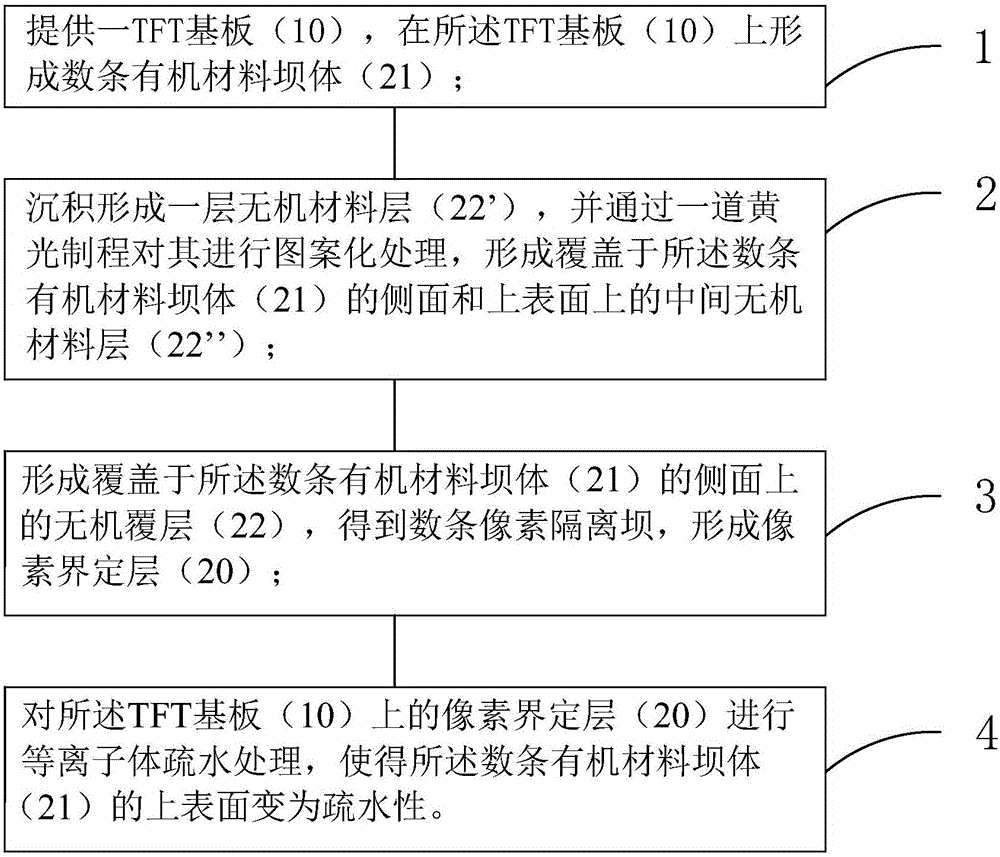

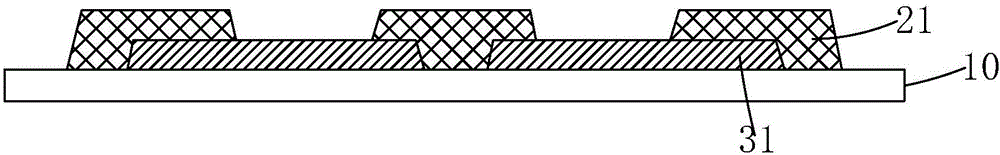

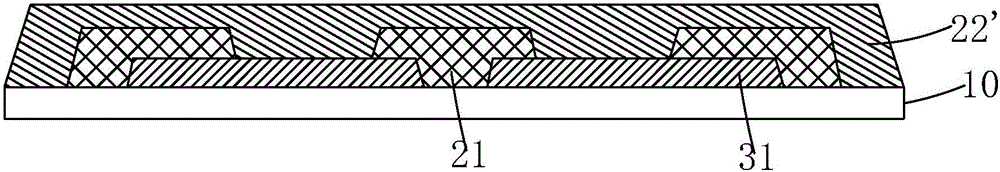

Manufacturing method for pixel defining layer and manufacturing method for OLED device

ActiveCN106129264AExtended service lifeImprove insulation performanceSolid-state devicesSemiconductor/solid-state device manufacturingInorganic materialsContact angle

The invention provides a manufacturing method for a pixel defining layer and a manufacturing method for an OLED device. According to the manufacturing method for the pixel defining layer, an inorganic covering layer is formed on side faces of organic material dam bodies to obtain multiple pixel isolation dams; then the multiple pixel isolation dams are subjected to plasma hydrophobic treatment to enable the upper surfaces of the organic material dam bodies to be hydrophobic in order to form the pixel defining layer; the upper surfaces of the pixel isolation dams are hydrophobic, so that ink can well enter pixel grooves without causing residue on the upper surfaces of the pixel isolation dams; the hydrophilic inorganic coating layer is arranged on the side faces of the pixel isolation dams, so that the ink can be well paved; a relatively large contact angle and a relatively thin film thickness are not caused by hydrophobicity of the side face; in addition, the side faces of the pixel isolation dams adopt the inorganic material; compared with the organic material, the inorganic material is more stable and higher in insulation; and meanwhile, the pixel defining layer is in contact with the OLED material, so that the OLED material can be more stable, and the service life of the OLED material can be prolonged.

Owner:SHENZHEN CHINA STAR OPTOELECTRONICS TECH CO LTD

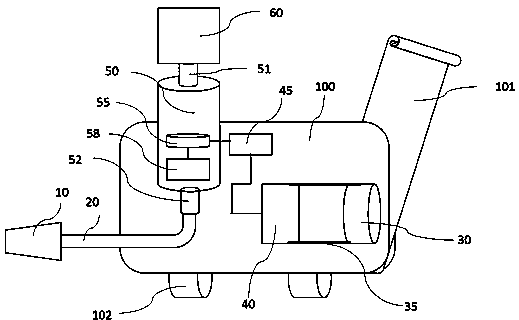

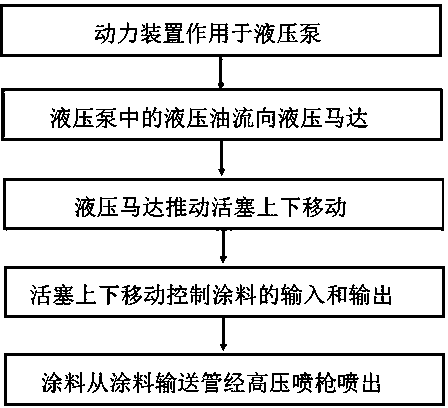

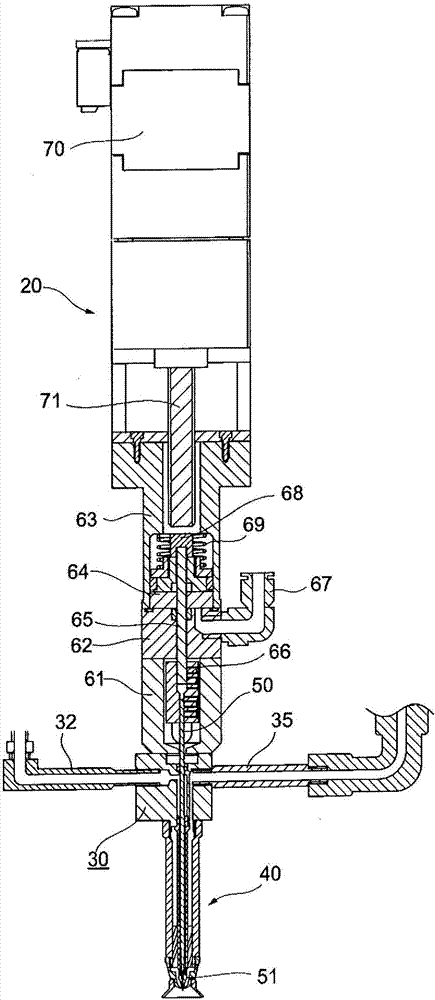

Automatic paint sprayer

The invention discloses an automatic paint sprayer. A power unit is arranged in a main machine housing. The power unit is used for controlling a hydraulic motor, the hydraulic motor is used for driving a piston in a paint storing device to move up and down, pressurization on paint in the paint storing device is achieved, and then the paint is conveyed into a high-pressure spray gun connected with a paint conveying pipe through the paint conveying pipe. By aiming the high-pressure spray gun at a target wall, the paint is sprayed on the wall. The automatic paint sprayer is not only suitable for spraying common paint coating materials but also particularly suitable for spraying high-viscosity paint coating materials, so that expensive thinner is saved. A paint film formed by the high-pressure spray gun in a sprayed mode is thick, high in hiding rare, high in quality, high in finish degree, and strong in adhesive force, and the paint film is uniformly formed on different walls in a sprayed mode without any brushmark. The automatic paint sprayer is small and exquisite, convenient to carry, small in compressor and light in weight. In addition, through the adoption of the automatic paint sprayer, working conditions are improved, the safety is improved, and wall painting is made to say goodbye to the age of manual work, low efficiency and simple tools.

Owner:昆山诺瑞信机械设备有限公司

Two-component PU (Polyurethane) paint

InactiveCN103320001AGood adhesionGood solvent resistancePolyurea/polyurethane coatingsPolymer scienceHardness

The invention relates to two-component PU (Polyurethane) paint. The two-component PU paint comprises the following components of: 18wt%-23wt% of polyurethane resin, 13wt%-16wt% of aliphatic isocyanate, 5wt%-8wt% of pigment, 3wt%-6wt% of packing, 1.5wt%-4.0wt % of additive and 45wt% to 60wt% of solvent. The two-component PU paint has excellent adhesiveness and solvent resistance and is applied to the coating of the surfaces of electronic products such as televisions, mobile phones, technological plastic products, refrigerators and washing machines. A paint film formed by coating the paint is smooth, bright, easy in application, thick and high in hardness, and has excellent interlayer adhesion, high solid content, good distinctness of image and abrasion performance. The paint with various colors and tones can be supplied according to the client requirements.

Owner:DANYANG JIAMEI CHEM

Photosensitive developed special line transfer glue for sapphire glass base material and preparation method thereof

InactiveCN108517196AImprove performanceGood synergyNon-macromolecular adhesive additivesPolyureas/polyurethane adhesivesPolyesterPhosphate

The invention discloses photosensitive developed special line transfer glue for a sapphire glass base material and a preparation method thereof. The photosensitive developed special line transfer glueis prepared from an acrylic ester active monomer, a photoinitiator, an acrylic acid phosphate assistant, a silane coupling agent, polyester acrylate, and urethane acrylate. The transfer glue does notcontain an organic solvent, and is environmentally friendly. A transfer technology is used as the foundation, and the advantages of a photosensitive developing technology are organically fused, the advantages are adopted and the defects are avoided. Especially, a product of the transfer glue not only can use the organic solvent for developing, but also can use pure water for developing, and is environmentally friendly, non-inflammable and non-explosible, and is a future tendency. The transfer glue has the excellent properties of solvent corrosion resistance, cold and thermal shock resistanceand the like after curing, and an adhesive force of a glue layer and the sapphire glass base material is excellent, especially, the adhesive force of the glue layer and the sapphire glass base material is greater than or equal to 4B after a water boiling test. The transfer glue is capable of solving problems of current UV glue that the adhesive force on the sapphire glass base material is poor, the water boiling is not resistant, and the solvent is not resistant.

Owner:SUZHOU BETELY POLYMER MATERIALS CO LTD +1

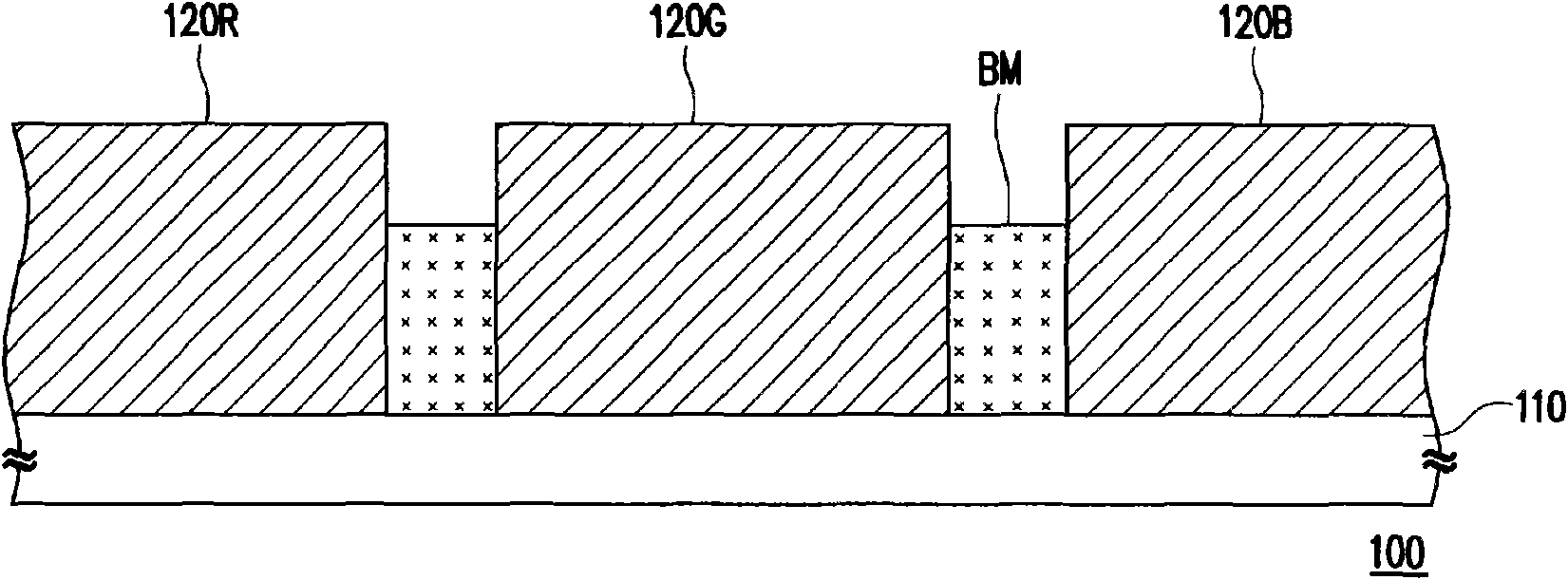

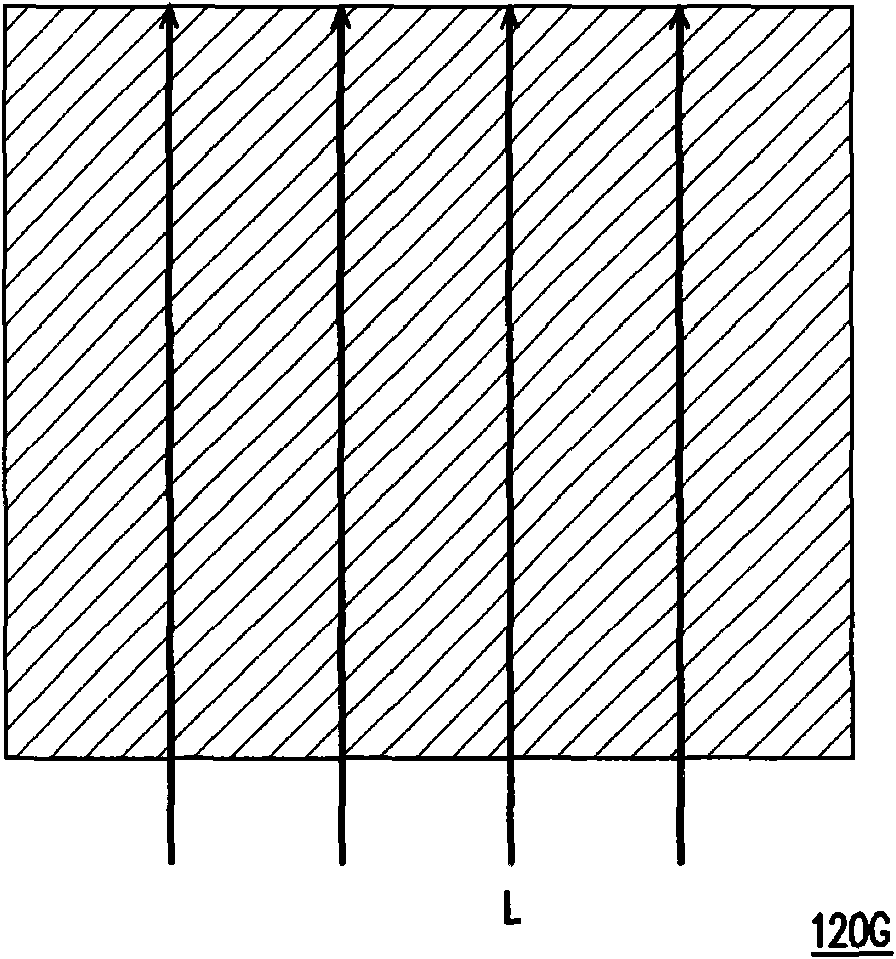

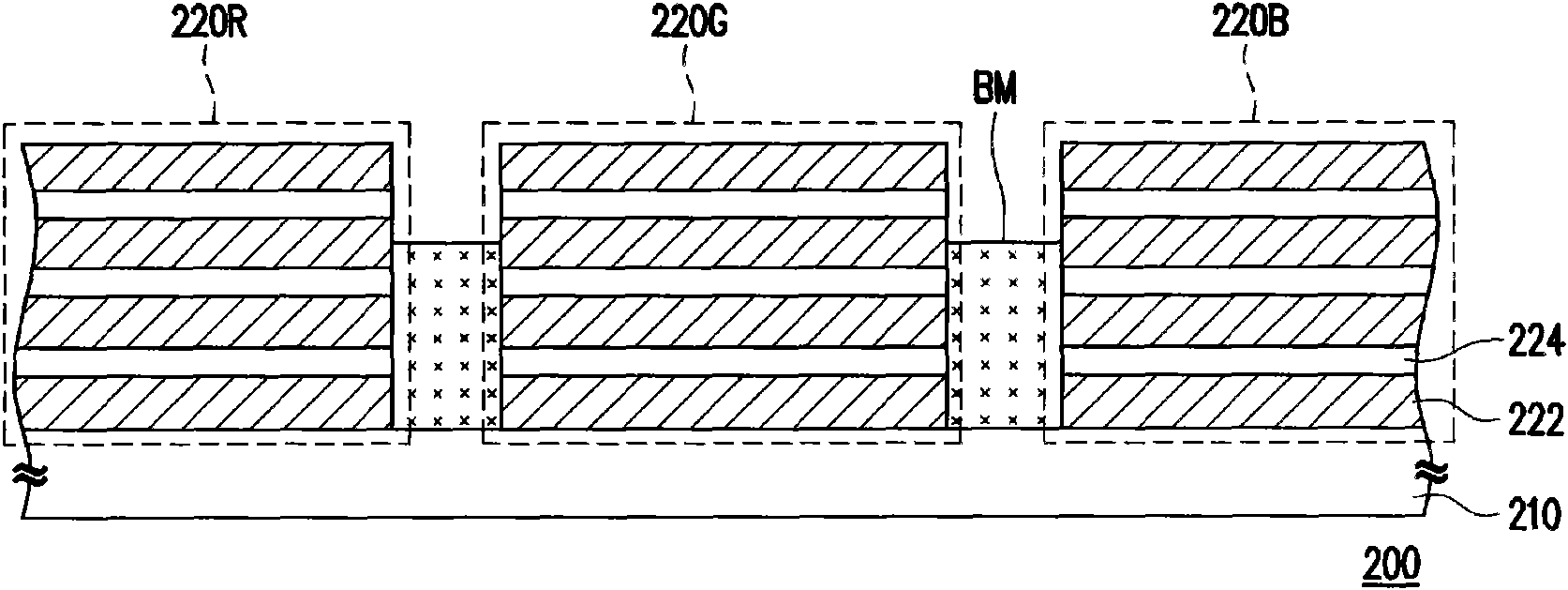

Color filter layer and manufacture method thereof

The invention discloses a color filter layer and a manufacture method thereof. The color filter layer comprises a substrate and a plurality of color filter stack patterns, wherein the color filter stack patterns are configured on the substrate. In addition, each of the color filter stack patterns comprises at least one pure color filter film and at least one modified color filter film which are stacked in a staggered way, and the refractive index of the modified color filter film is different from that of the pure color filter film.

Owner:华映视讯(吴江)有限公司 +1

Plastic surface varnish priming paint

The invention relates to a plastic surface varnish priming paint. The plastic surface varnish priming paint comprises: 18-25 wt% of thermoplastic acrylic resin, 8-15 wt% of a filling material, 3-8 wt% of a pigment, 1.0-2.0 wt% of an auxiliary agent and 50-70 wt% of a solvent. The plastic surface varnish priming paint of the invention has excellent adhesive force and is applicable to plastic articles such as ABS, PC and the like. The varnish priming paint has easy construction and high solid content; and the coating formed paint film is flat, shining, thick in formed film, high in hardness, good in distinctness of image, and high in wear resistance, and also products with various colors can be provided according to client demands.

Owner:DANYANG JIAMEI CHEM

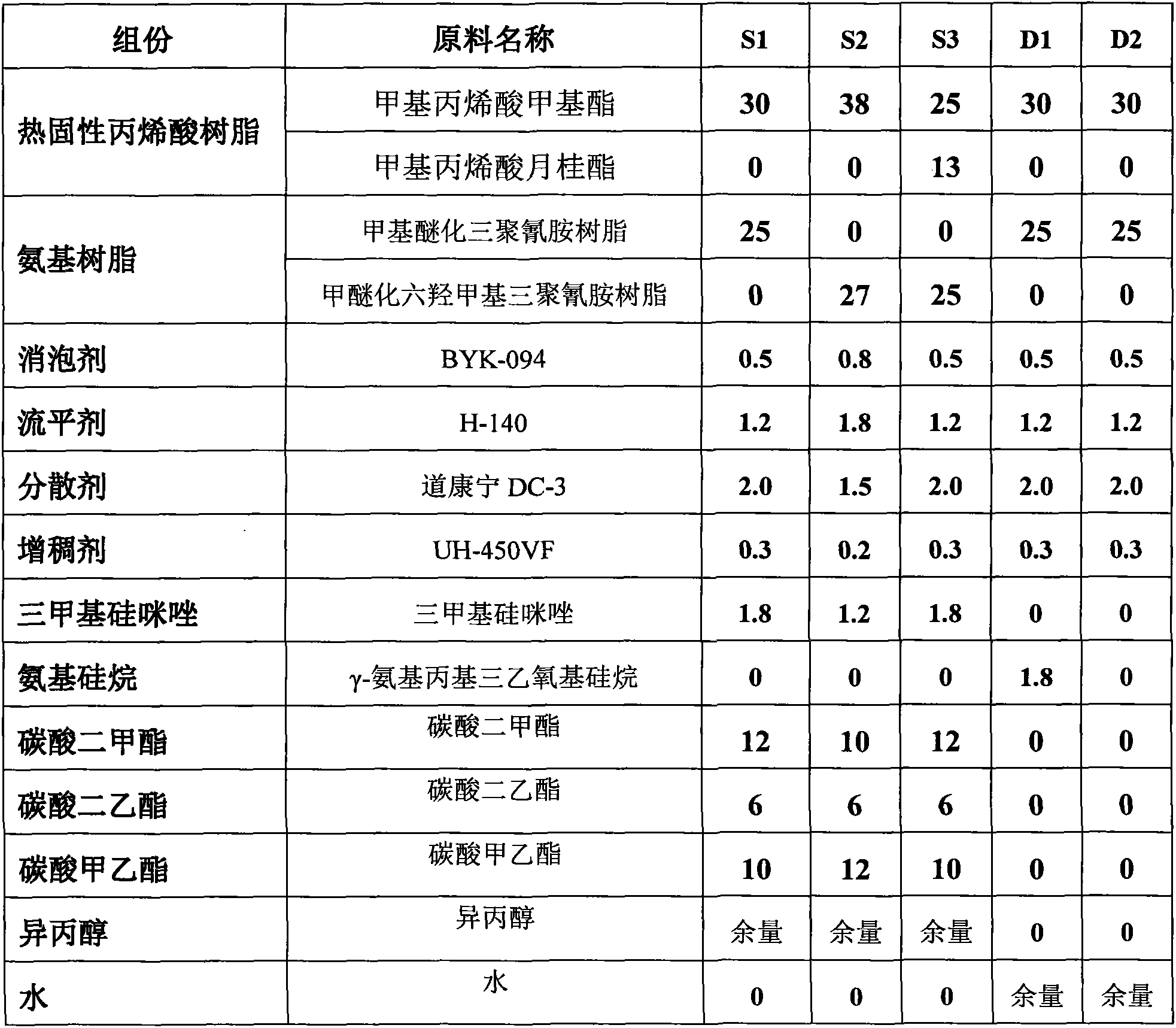

Special finishing paint for thermosetting acrylic hubs

The invention relates to a special finishing paint for thermosetting acrylic hubs. The finishing paint comprises the following components: 30-38wt% of thermosetting acrylic resin, 20-27wt% of amino resin, 3.5-5.0wt% of aids and 30-40wt% of solvent. The finishing paint has the beneficial effects that the finishing paint has excellent adhesiveness and solvent resistance and is suitable for the automobile hubs, bicycles, motorcycles, cars and the like; and the films formed by coating the paint are flat and thick and have high construction solids, good levelling property, high fullness, high lusters, high hardness and excellent weather resistance.

Owner:DANYANG JIAMEI CHEM

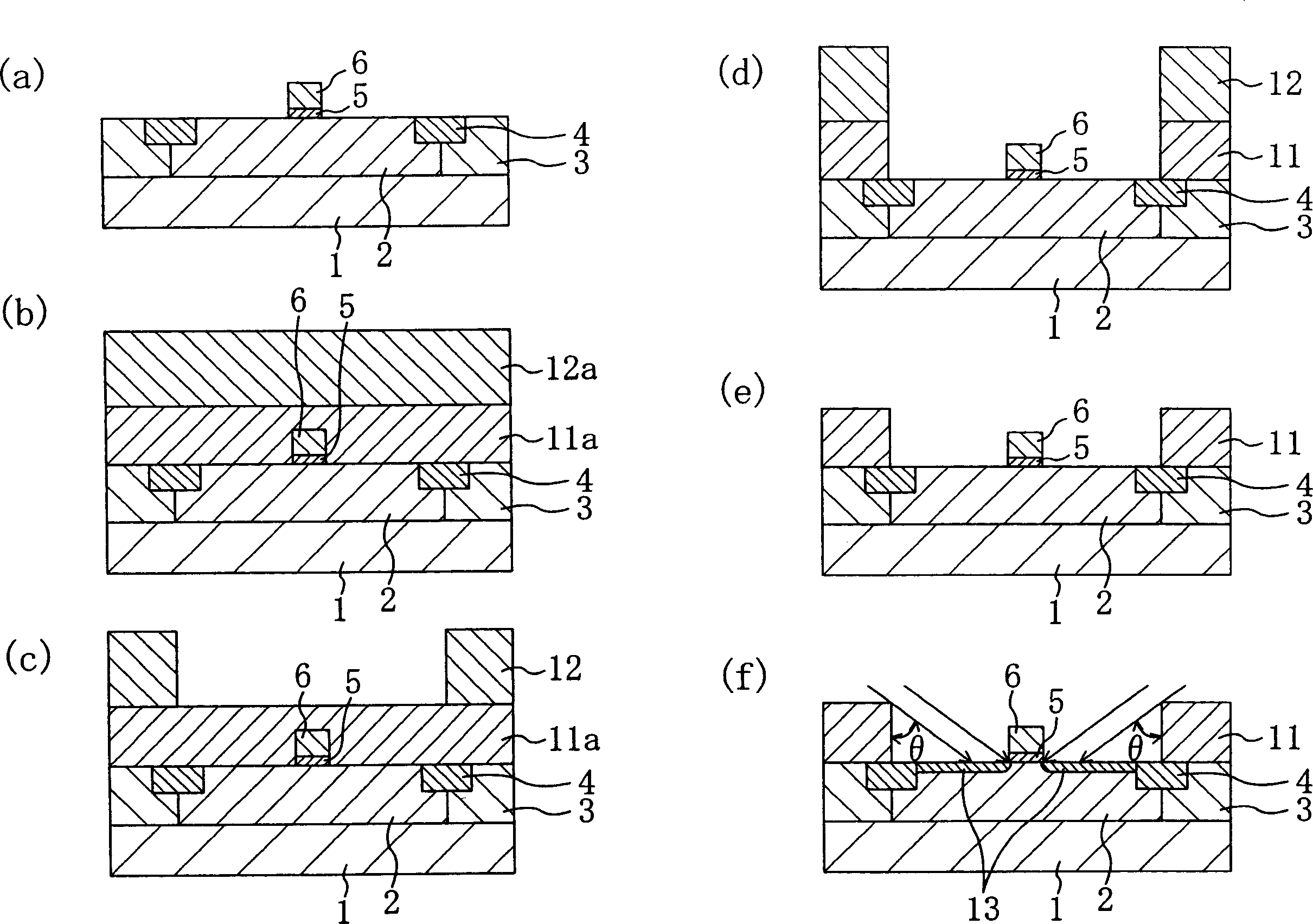

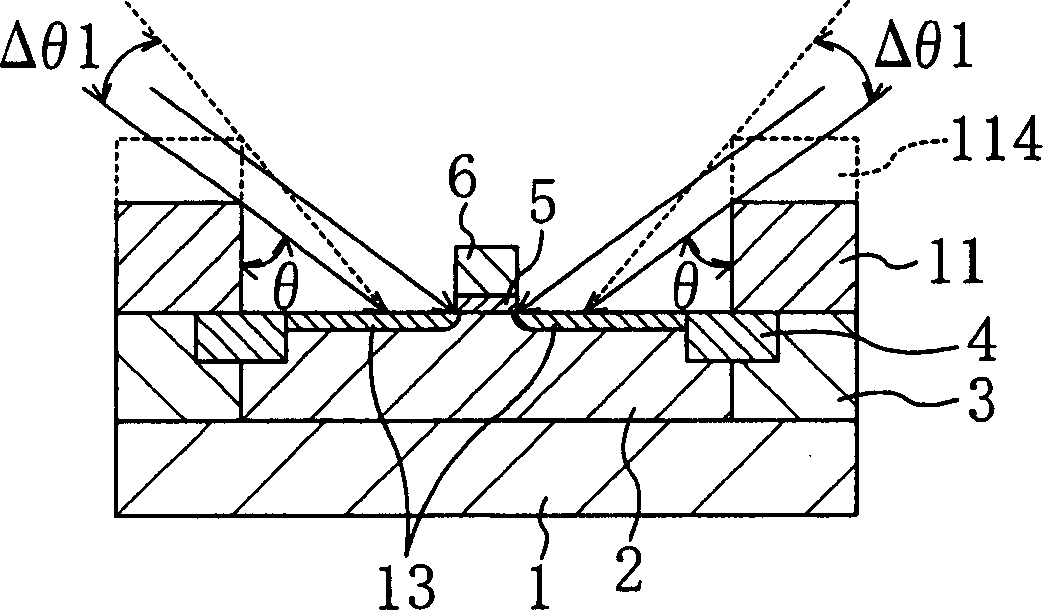

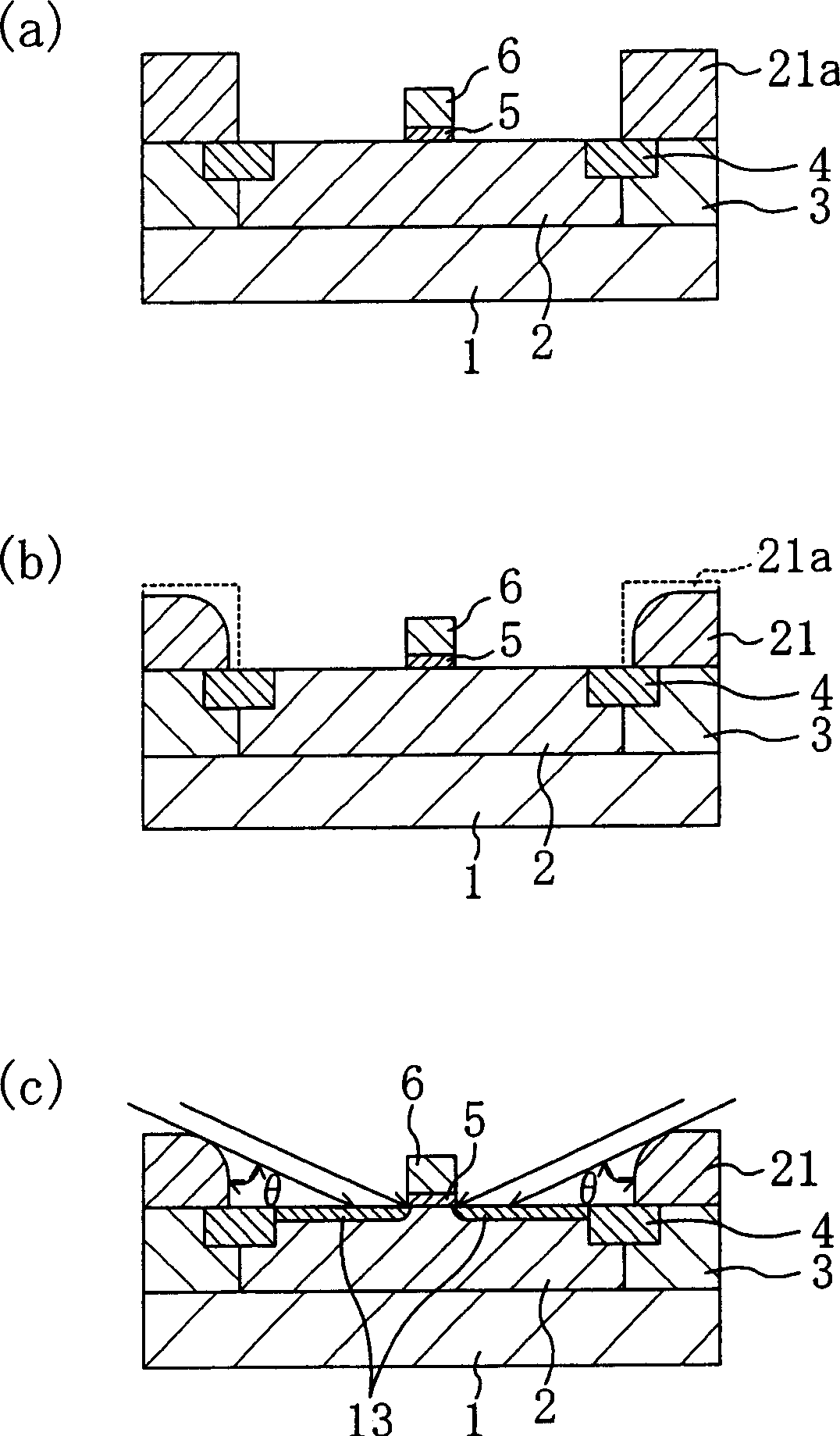

Manufacturing method of semiconductor device

InactiveCN1497679AImprove the blocking effectFilm thicknessTransistorSemiconductor/solid-state device manufacturingImpurityIon implantation

A hard mask 21a which has an opening for exposing a p-type region 2 defined in a silicon substrate 1 and is made of, for example, a BPSG film is formed. Then, the hard mask 21a is subjected to isotropic etching using argon gas, to have its edge rounded off, thereby forming an implantation hard mask21 having a tapered edge. Subsequently, large-angle-tilt ion implantation of an n-type impurity is performed using the implantation hard mask 21 as a mask, thereby forming an n<-> layer 13 having an LDD structure. Thereafter, the implantation hard mask 11 is removed. In this manner, it is possible to perform large-angle-tilt ion implantation using an implantation mask thinner than a conventional implantation mask.

Owner:PANASONIC CORP

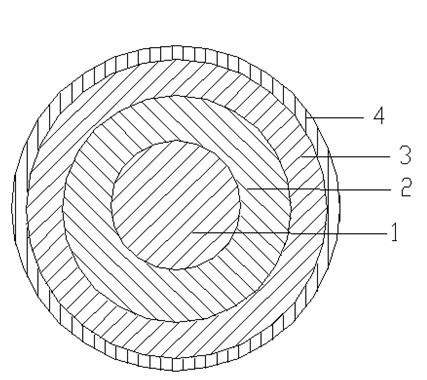

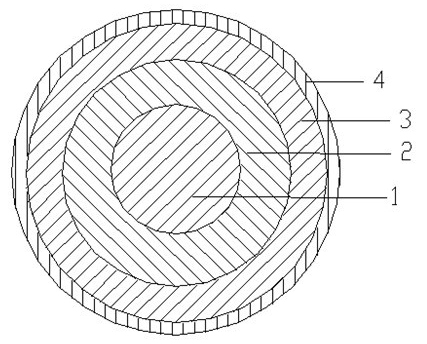

Enamelled wire for network transformer

InactiveCN101923917AFilm thicknessHigh withstand voltagePlastic/resin/waxes insulatorsTransformers/inductances coils/windings/connectionsElectrical conductorTransformer

The invention relates to an enamelled wire for a network transformer, which comprises a copper core conductor and a high temperature-resistant polyurethane coating layer as well as a neloy paint layer which are arranged out of the copper core conductor, wherein the volume of the high temperature-resistant polyurethane coating layer and the neloy paint layer is 40-60% of that of the enamelled wire for the network transformer; and the volume of the neloy paint layer is 1-3% of that of the enamelled wire. The manufacture method of the enamelled wire comprises the following steps of: firstly dragging copper material to be a naked copper wire; cleaning and annealing the naked copper wire; coating an insulated paint layer with a felt and baking, wherein the paint is coated at 15-20 ways, the paint is coated for once, and the baking is performed for once; and coating a layer of the neloy paint layer on the surface of the insulating paint layer and baking. The enamelled wire has the advantages of thick paint film, high voltage resistance, large elongation percentage, large tensile strength and the like, and can be applied to electric devices with high correlative machining requirement, small space requirement and the like such as the network transformer and the wave filter, etc.

Owner:诚信漆包线(惠州)有限公司

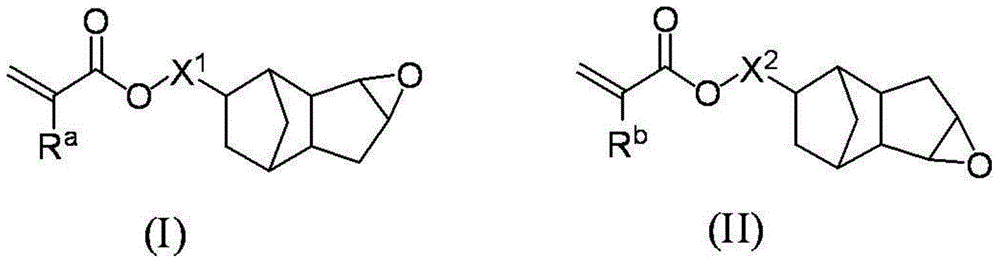

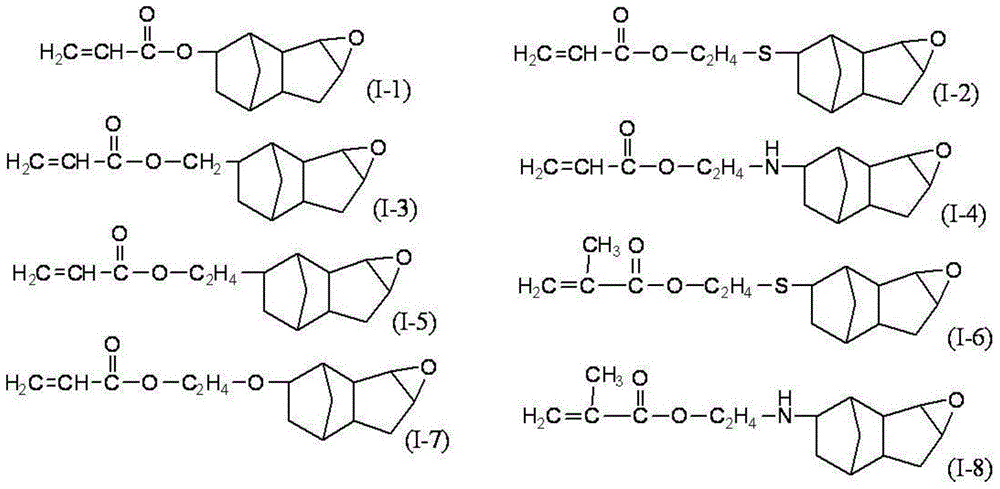

Colored photosensitive resin composition

ActiveCN105842985AImprove solubilityFilm thicknessOptical filtersPhotosensitive materials for photomechanical apparatusSolubilityPigment

The subject of the invention is to provide a colored photosensitive resin composition which has excellent solubleness in developing solution and can be used to prepare specific patterns, can provide highly precise colored filters with thin films. The invention relates to the colored photosensitive resin composition comprising a colorant(A), a resin(B), a polymerizable compound(C), a polymerization initiator(D). The colorant(A) contains at least one kind selected from the group consisting of C. I. pigment green 58, C.I. pigment yellow 185 and C.I. pigment yellow 138.

Owner:SUMITOMO CHEM CO LTD

Electrode active substance and method for producing same

InactiveCN103403932AGood film quality and cheapImprove featuresCell electrodesPhosphorus compoundsSuspended particlesSlurry

Owner:SUMITOMO OSAKA CEMENT CO LTD

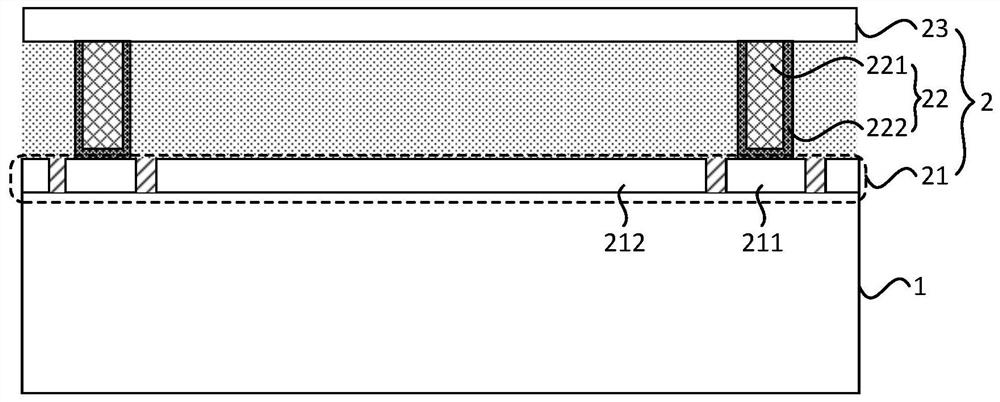

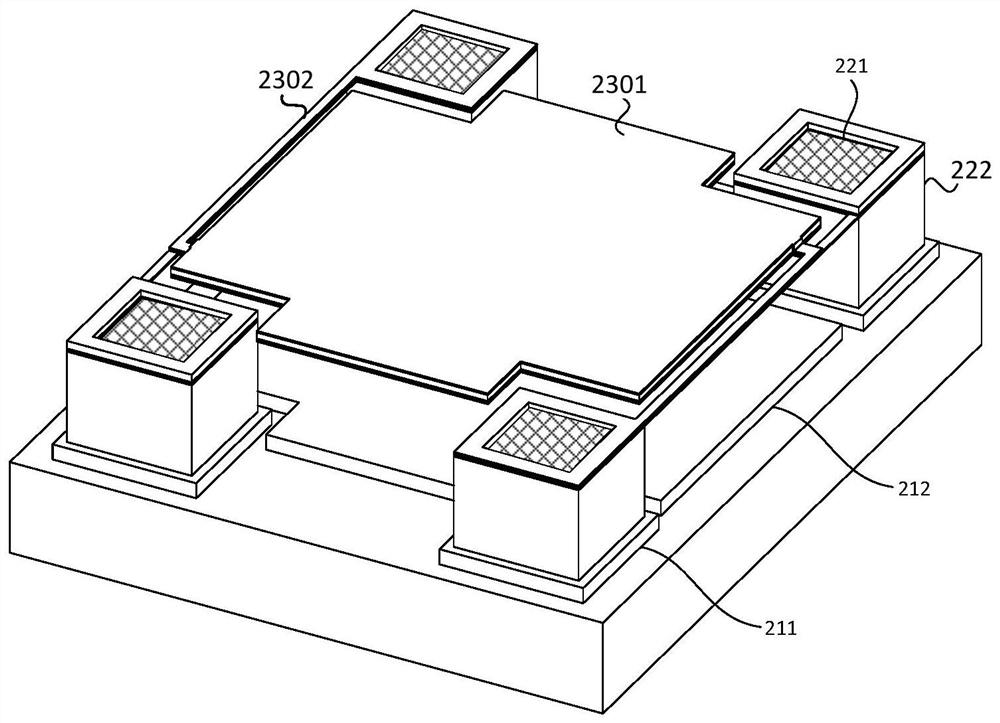

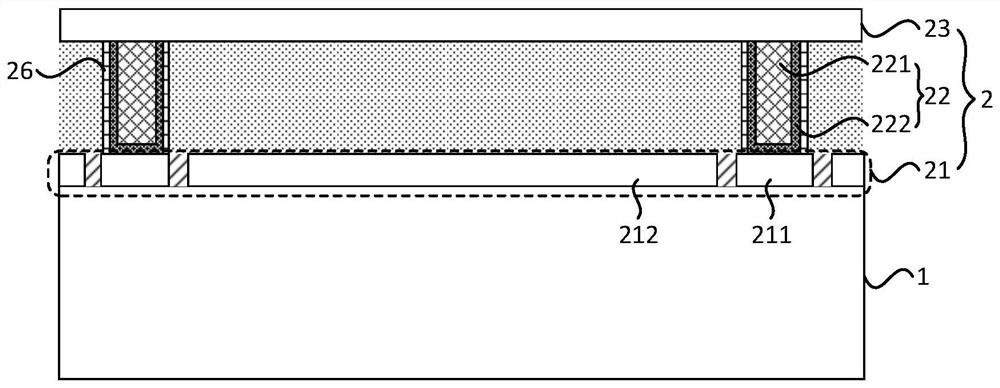

Light-emitting device and manufacturing method thereof

InactiveCN102726121AHigh exothermic propertiesFilm thicknessElectroluminescent light sourcesSolid-state devicesEngineeringOrganic electroluminescence

Owner:SUMITOMO CHEM CO LTD

Method for repairing automobile hub scratch

InactiveCN108944828AEasy to fixEasy to implementRevolution surface grinding machinesAnti-corrosive paintsPre treatmentVarnish

The invention provides a method for repairing an automobile hub scratch and relates to the technical field of automobiles. The method for repairing the automobile hub scratch includes the following steps of (1) hub scratch pre-treatment, (2) blending agent blade coating, (3) refinishing paint spraying, (4) varnish spraying and (5) polishing. By the adoption of the method for repairing the automobile hub scratch, the hub scratch position is repaired, the whole repairing process is simple and easy to achieve, an action effect is remarkable, repairing used time is short, work efficiency is improved, and the effect that time and labor are saved is achieved.

Owner:广西速道汽车维修服务有限公司

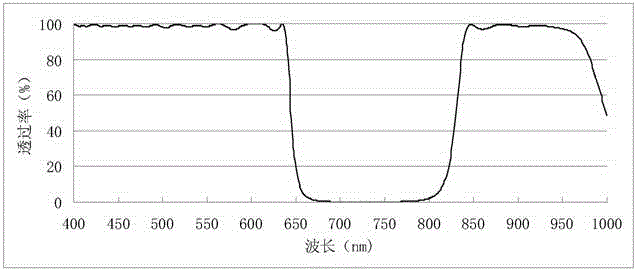

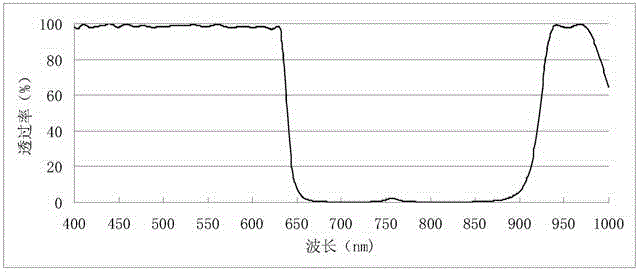

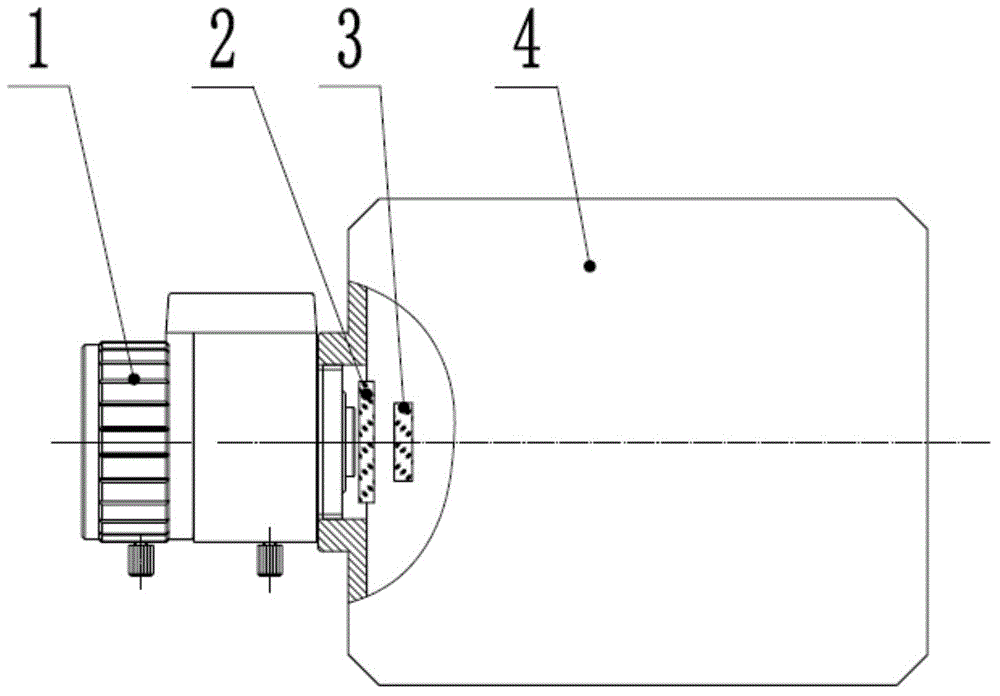

Camera shooting method and device of day and night lens without IR-Cut (infrared-cut) switcher

ActiveCN104660896AEasy to useSmall sizeTelevision system detailsOptical filtersTransmittanceImage sensor

The invention relates to a camera shooting method and device of a day and night lens without an IR-Cut (infrared-cut) switcher. An optical light-transmitting element in front of, in the middle of or behind the lens is plated with a filter coating, or the optical light-transmitting element provided with the film coating is additionally arranged in front of, in the middle of or behind the lens; the filter coating has the characteristics that transmittance of light with the wavelength of 400-640 nm or 840-970 nm is increased, the average transmittance of the light with the wavelength of 400-640 nm or 840-970 nm is higher than 98%, light with the wavelength of 670-800 nm is cut off and the average transmittance of the light with the wavelength of 670-800 nm is lower than 0.4%; moreover, a color correction unit with functions of separating and eliminating infrared component signals in image signals is additionally arranged in an image signal processor connected with an image sensor. The method and the device can radically solve a problem of slight red images shot by a camera at day time without the IR-Cut switcher, truly realize day and night use of the lens, and can guarantee that the lens is reliably used.

Owner:SANMING FOCTEK PHOTONICS INC

Anti-shielding conductive coating

InactiveCN103333574BGood adhesionStrong adhesionElectrically-conductive paintsAcrylic resinConductive coating

The invention relates to an anti-shielding conductive coating. The conductive coating comprises 20-25wt% of acrylic resin, 15-20wt% of conductive powder, 1.5-3.5wt% of aids and 57-63wt% of solvent. The anti-shielding conductive coating has excellent adhesiveness and is suitable for coating electromagnetic shielding coatings on the surfaces of mobile phones, notebook computers and audiovisual instruments. Films formed by coating the coating have good adhesive forces, are easy to construct and are thick. Anti-shielding conductive films can be formed after the anti-shielding conductive coating is coated.

Owner:DANYANG JIAMEI CHEM

Corrosion inhibitor resistant to H2S and CO2

InactiveCN100591803CReduce dosageImprove efficiencyBorehole/well accessoriesIsopropyl alcoholFatty alcohol

The invention relates the chemical engineering field, especially a H2 and CO2 inhibiter. H2 and CO2 are produced accompany to oil-gas field exploitation and transfusion process, and can corrode exploitation equipment. The inhibiter contains at least (by wt. %): isopropyl alcohol 10-30, fatty alcohol polyoxyethylene ether .1-0.5, and litol polyoxyethylene ether 0.1- 1.0. The inhibiter can be used in oil / water well with high temperature and pressure, and has the advantages of good corrosion resistance, low consumption, low cost and high efficiency.

Owner:CHINA NAT PETROLEUM CORP CHUANQING DRILLING ENG CO LTD

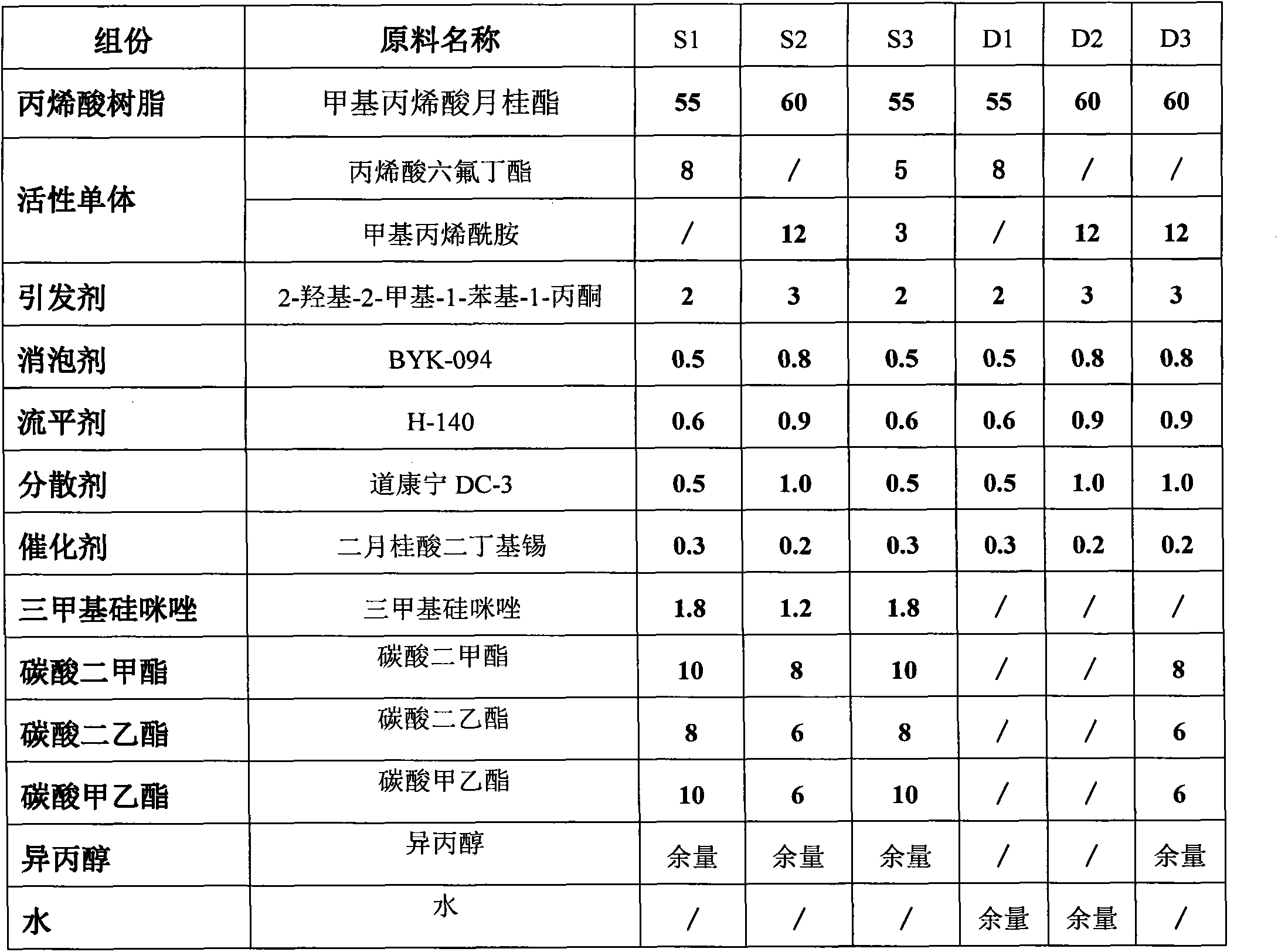

Photocuring finishing paint

The invention relates to a photocuring finishing paint comprising the following components: 55-65wt% of acrylic resin, 5-10wt% of active monomers, 2-5wt% of initiator, 2.5-4.0wt% of assistant and 20-35wt% of solvent. The photocuring finishing paint provided by the invention has excellent adhesiveness and solvent resistance and is suitable for being used as the finishing paint for IT products such as a television, a motorcycle, an automobile lamp, a mobile phone, a notebook computer and the like. A paint film formed by coating is flat and bright, thick in formed film, high in hardness, good in distinctness of image, high in fullness and excellent in wear resistance and petrol resistance.

Owner:DANYANG JIAMEI CHEM

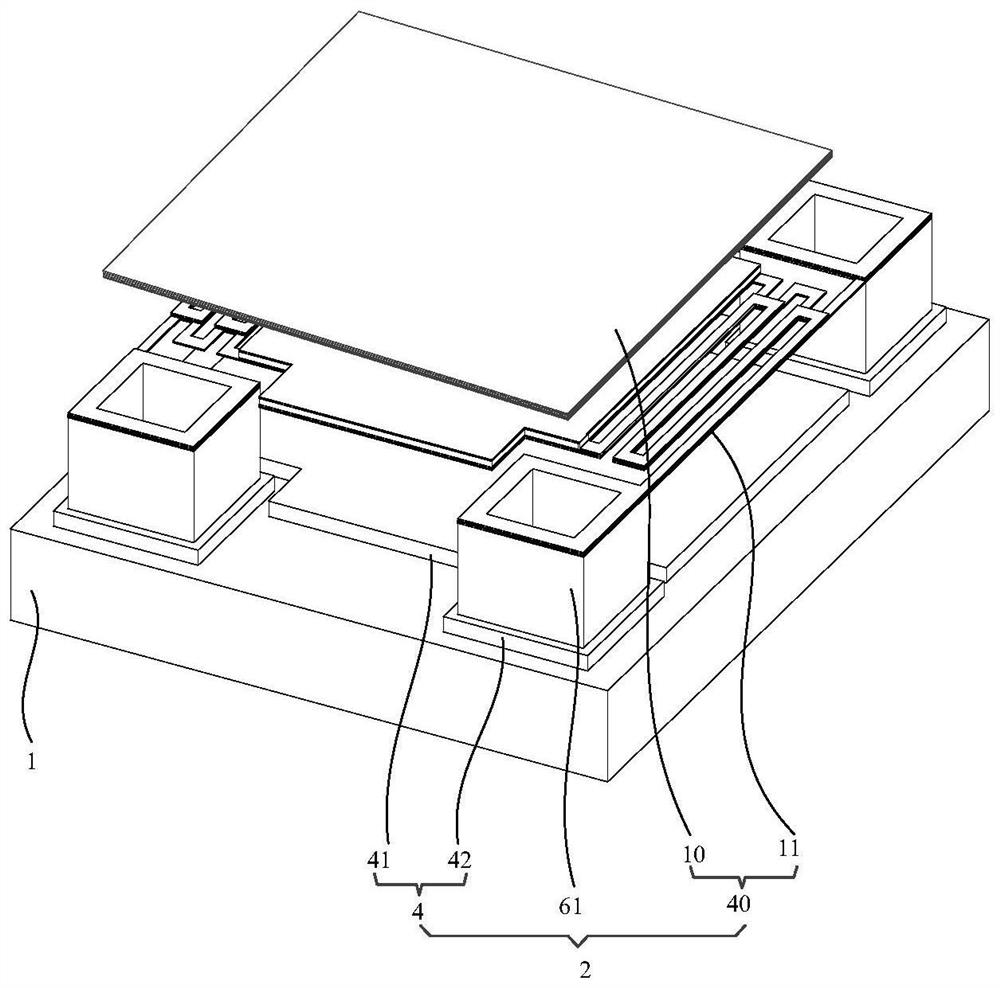

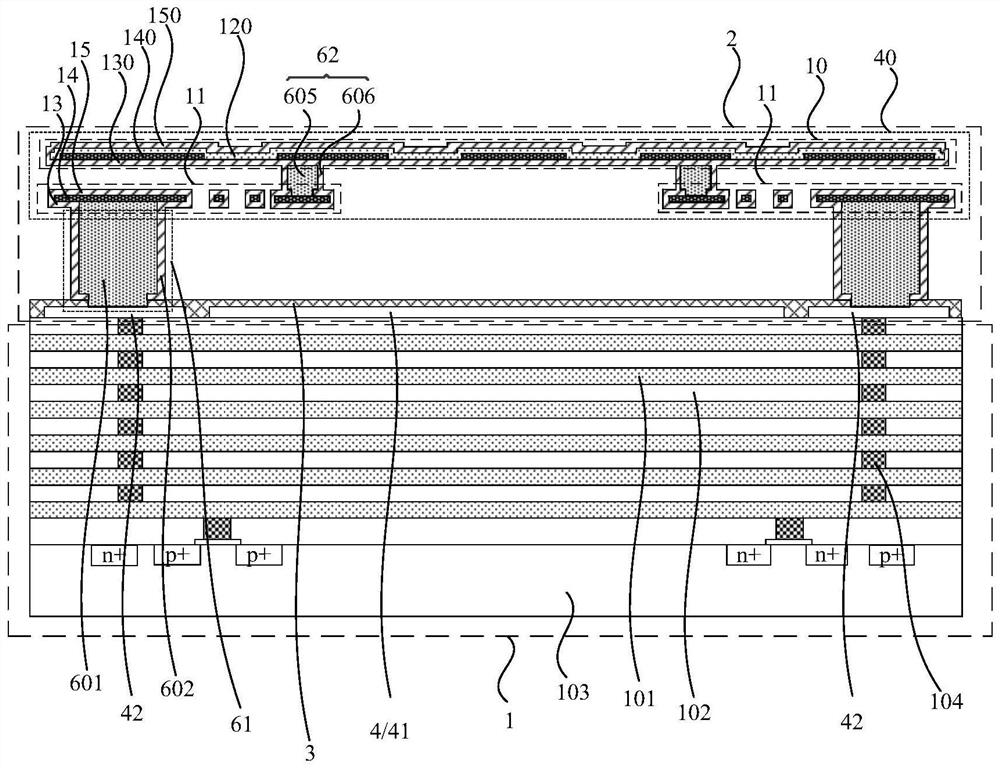

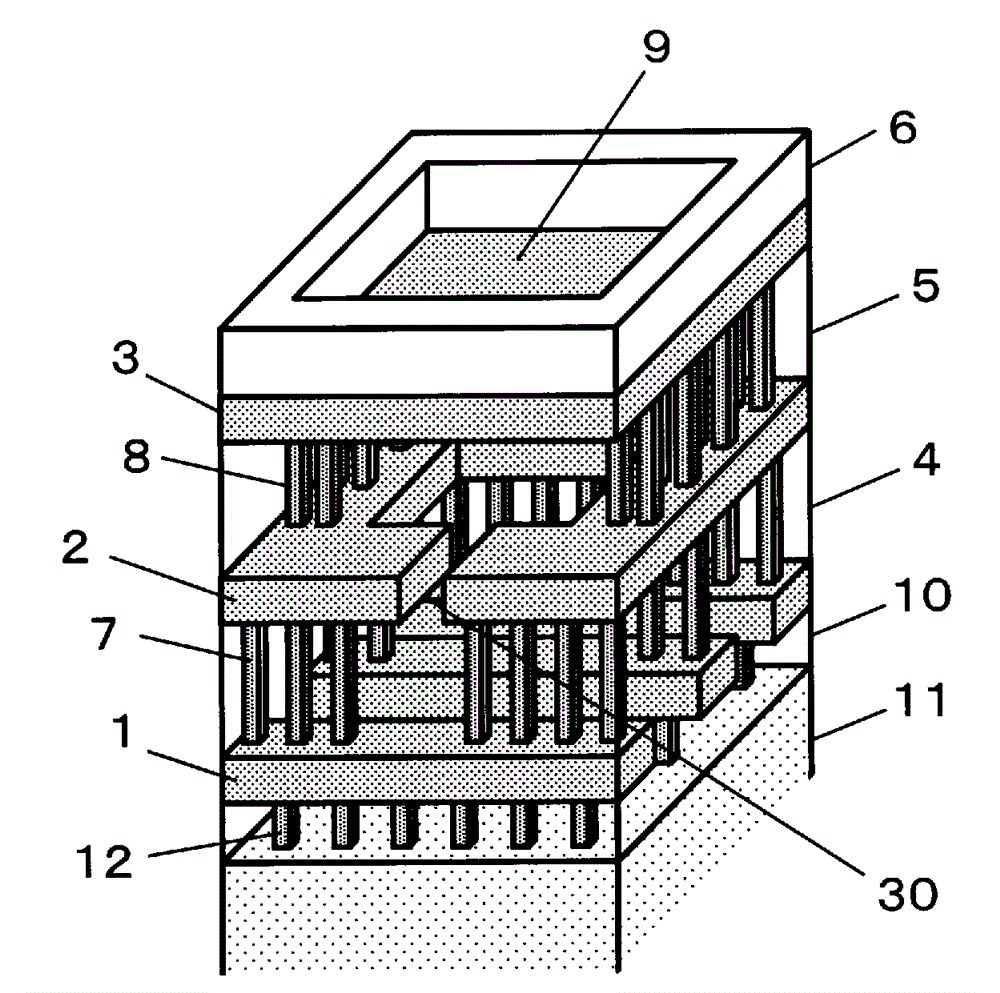

Infrared focal plane detector

ActiveCN113447148AIncrease duty cycleLow thermal conductivityFinal product manufacturePyrometry using electric radation detectorsFocal plane detectorOptical polarization

The invention relates to an infrared focal plane detector, a CMOS measurement circuit system and a CMOS infrared sensing structure in the infrared focal plane detector are both prepared by using a CMOS process, in the infrared focal plane detector, a first columnar structure is located between a reflecting layer and a beam structure, a second columnar structure is located between an absorption plate and the beam structure, the first columnar structure and the second columnar structure are solid columnar structures, and the infrared focal plane detector further comprises a metamaterial structure and / or a polarization structure. Through the technical scheme of the invention, the problems of low performance, low pixel scale, low yield and poor consistency of a traditional MEMS process infrared focal plane detector are solved, the structural stability of the infrared focal plane detector is improved, the area of the absorption plate is increased, the infrared detection sensitivity of the infrared focal plane detector is improved, the absorption rate of the infrared focal plane detector to incident infrared electromagnetic waves is improved, the performance of the infrared focal plane detector is optimized, and the difficulty of optical design of the infrared focal plane detector is reduced.

Owner:BEIJING NORTH GAOYE TECH CO LTD

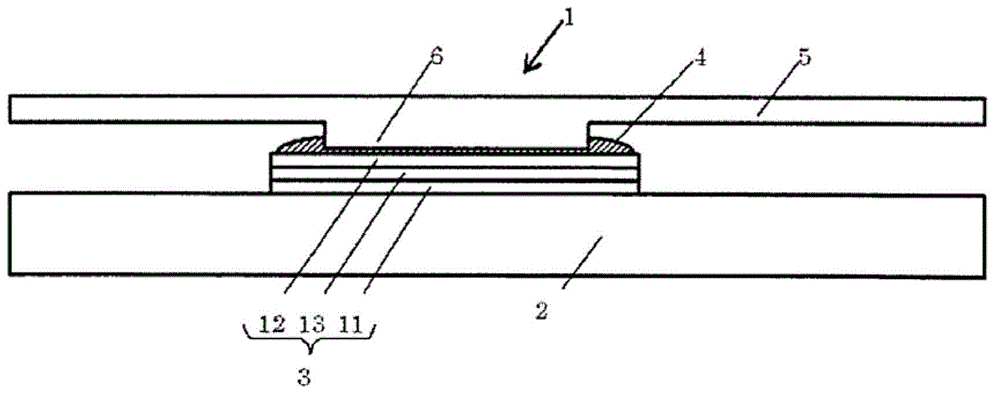

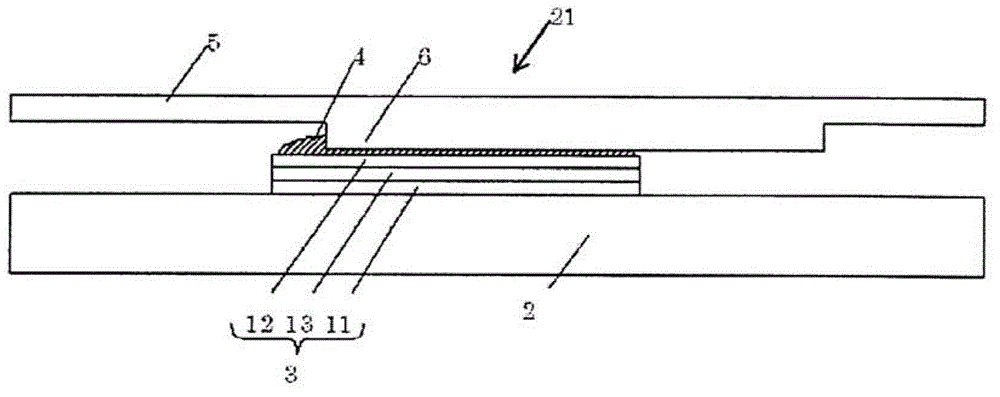

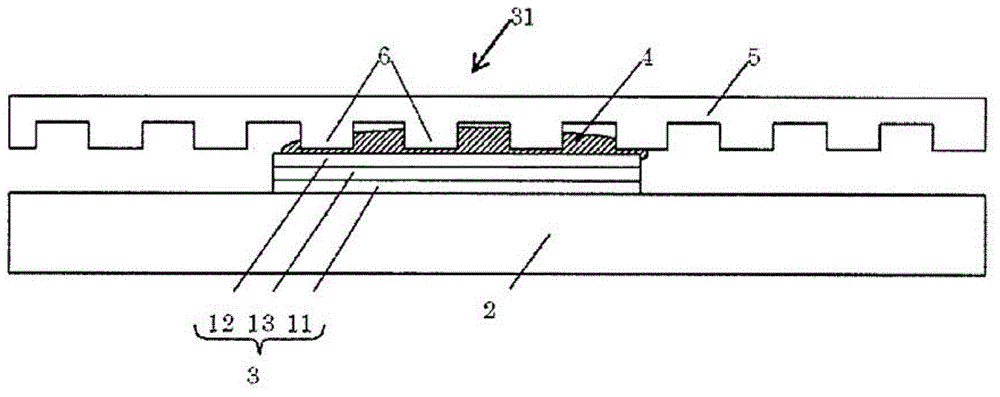

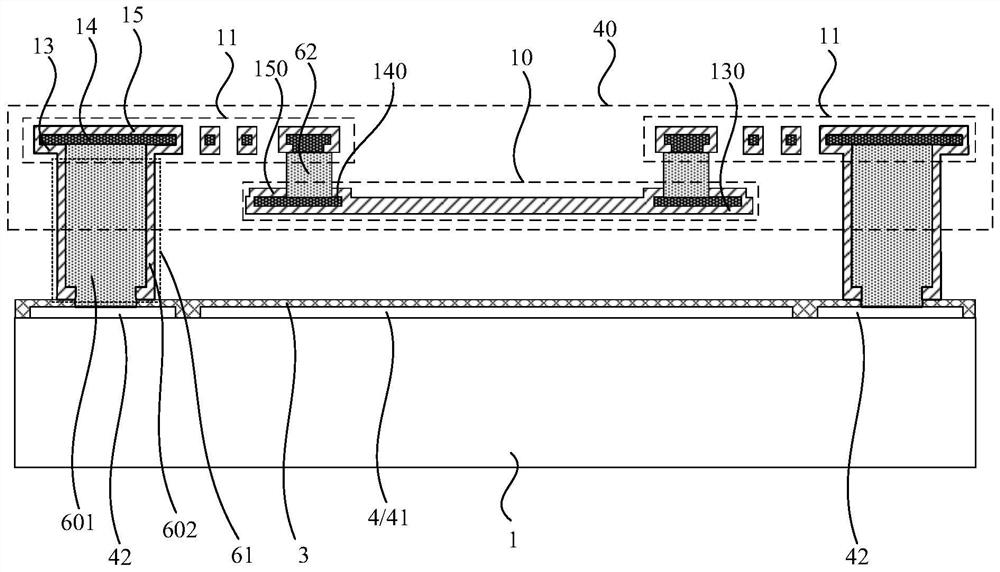

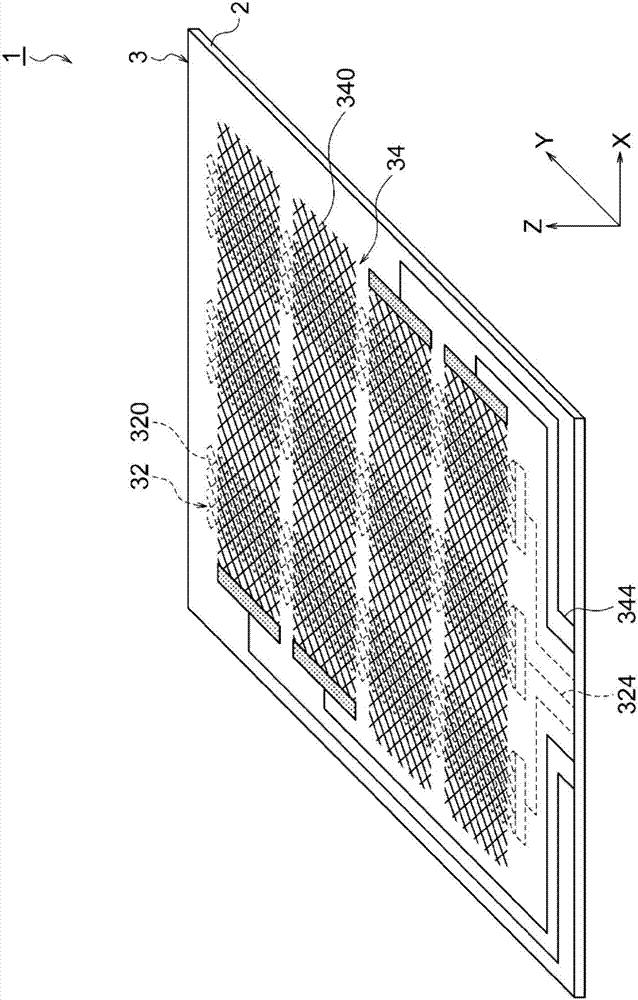

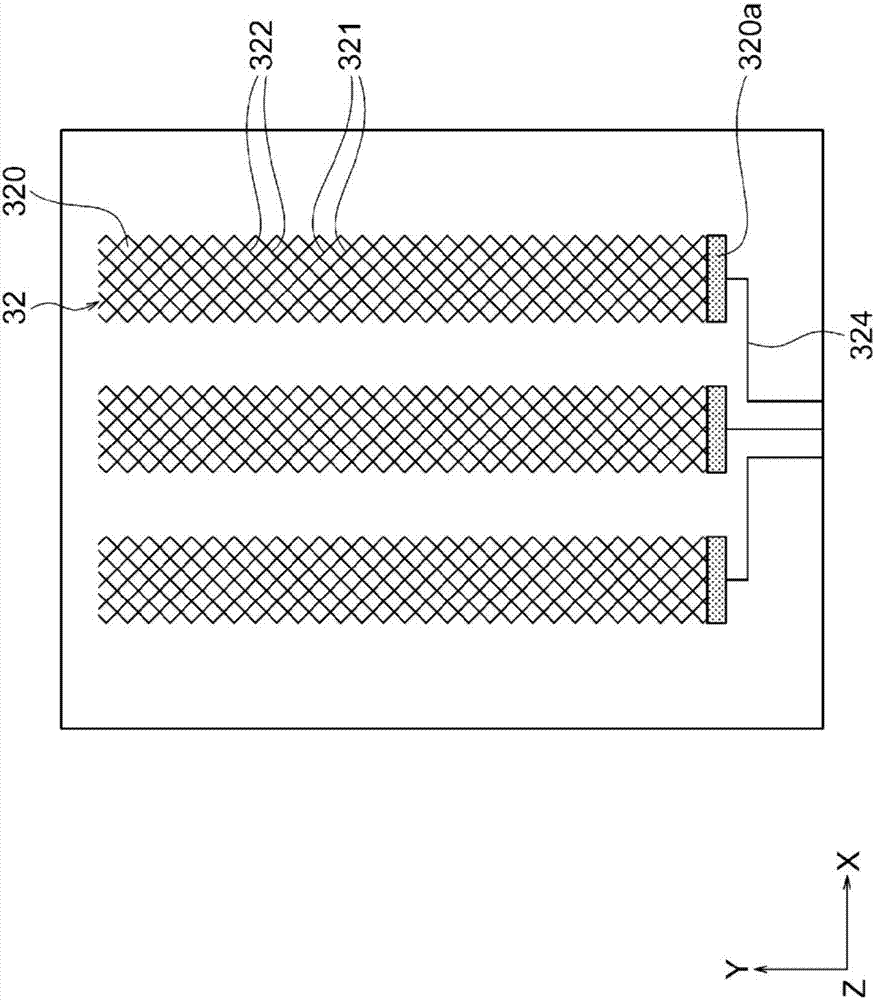

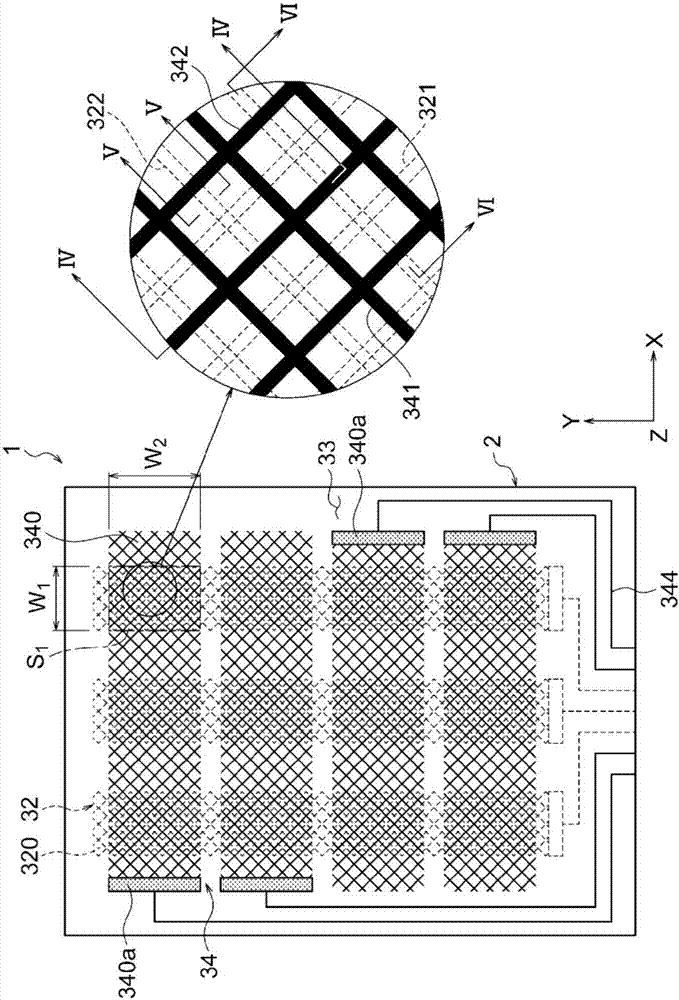

Touch sensor wiring body, touch sensor wiring substrate, and touch sensor

InactiveCN107407997AFilm thicknessPrevent deterioration of electrical characteristicsInput/output processes for data processingElectrical conductorEngineering

A touch sensor wiring body (3) equipped with a first resin layer (31), a first conductor layer (32) having a first conductor line (322) and provided on the first resin layer (31), a second resin layer (33) for covering the first conductor layer (32), and a second conductor layer (34) having a second conductor line (342) and provided on the first conductor layer (32) with the second resin layer (33) interposed therebetween, wherein the first and second conductor layers (32, 34) are electrically insulated by the second resin layer (33), and satisfy formula (1). D1<D2 (1) Herein, D1 represents the thickness of the first resin layer (31) in a first region corresponding to the first conductor line (322) in a first prescribed cross-section that transects the touch sensor wiring body (3) along the second conductor line (342), while D2 represents the thickness of the second resin layer (33) in the first region of the first prescribed cross-section.

Owner:THE FUJIKURA CABLE WORKS LTD

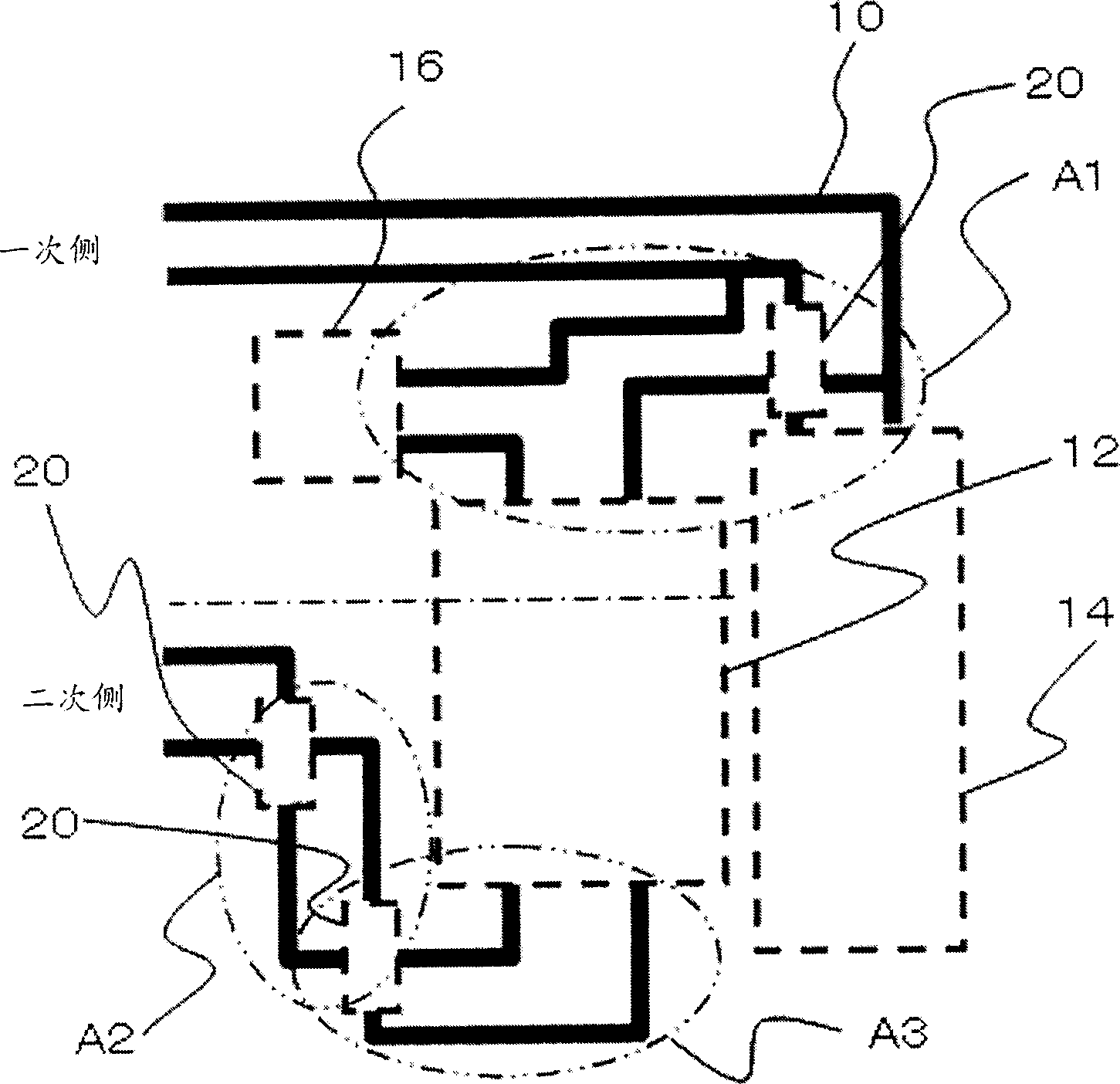

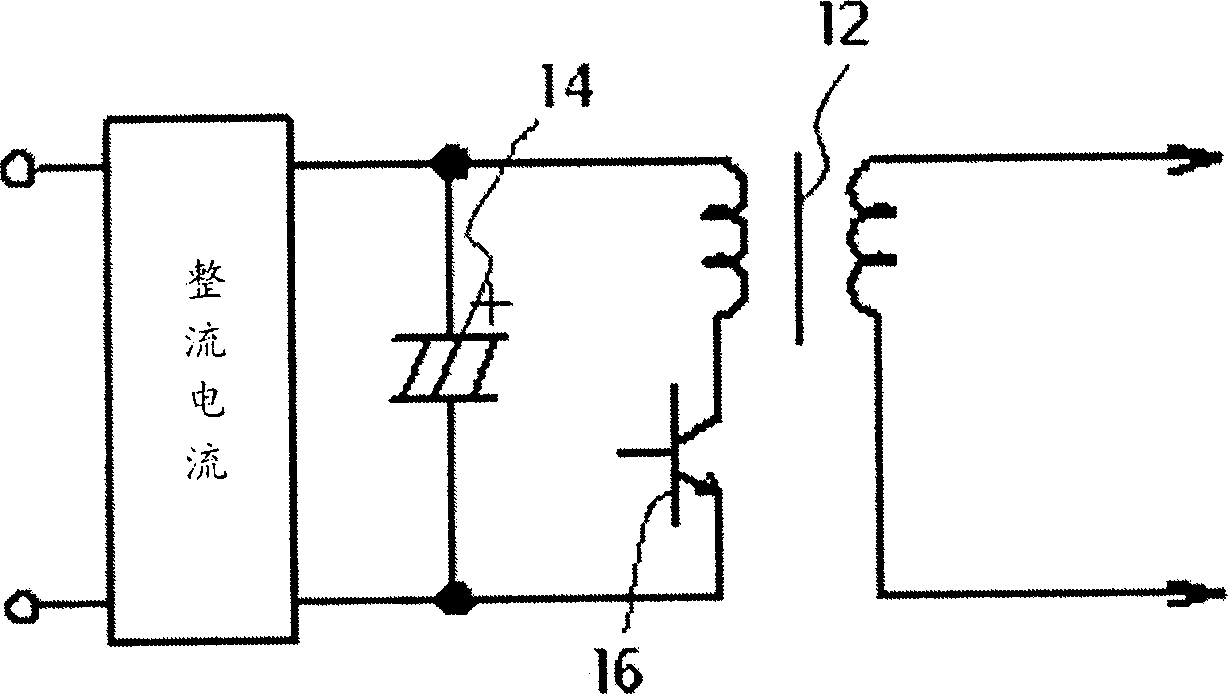

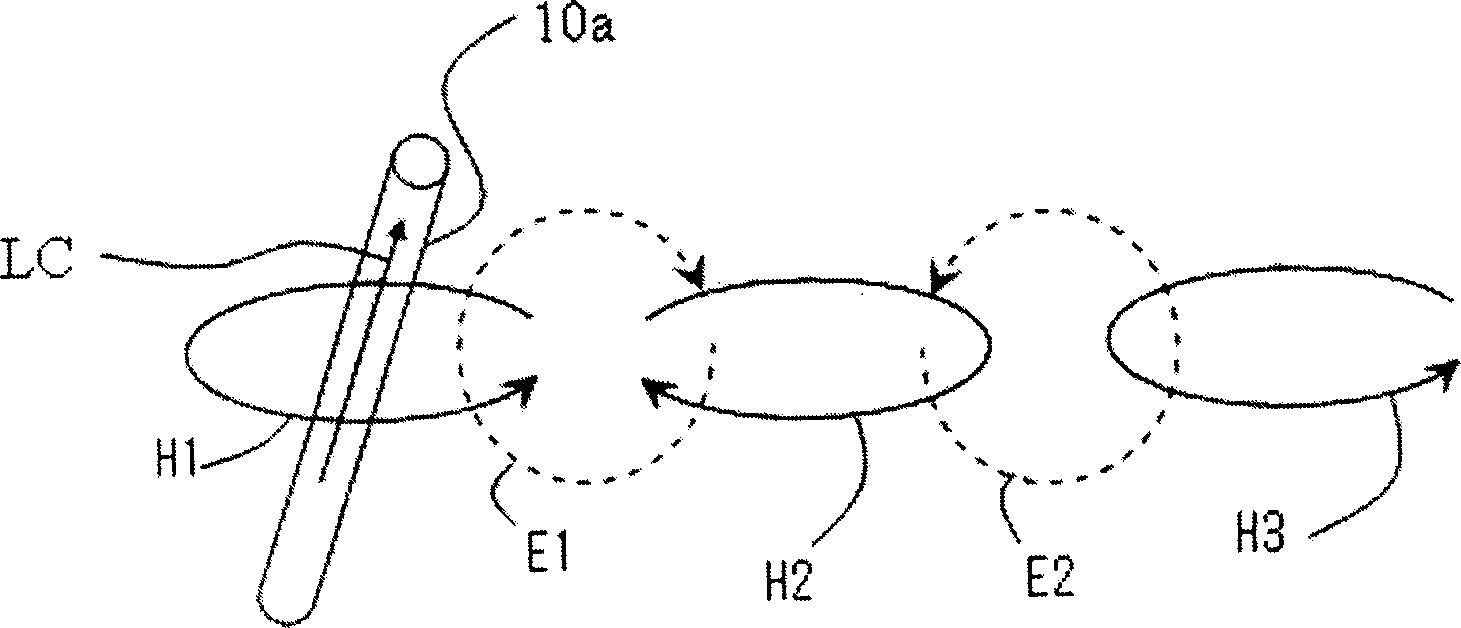

Wiring board, electronic device, and power supply unit

InactiveCN1893763AHigh frequency current attenuationDoes not block current componentsMetallic pattern materialsEngineeringLead frame

The present invention relates to a wiring board, electronic device, and power supply unit. A wiring board (lead frame) 10 has a configuration in which a high-frequency current suppression member 18 formed of a conductive soft magnetic film 18a having high magnetic permeability is provided in a near field (magnetic field dominant area) in a lead frame part (wiring part) 10a which can be a radiation noise source, preferably, in the periphery of the lead frame part 10a.

Owner:ORMON CORP

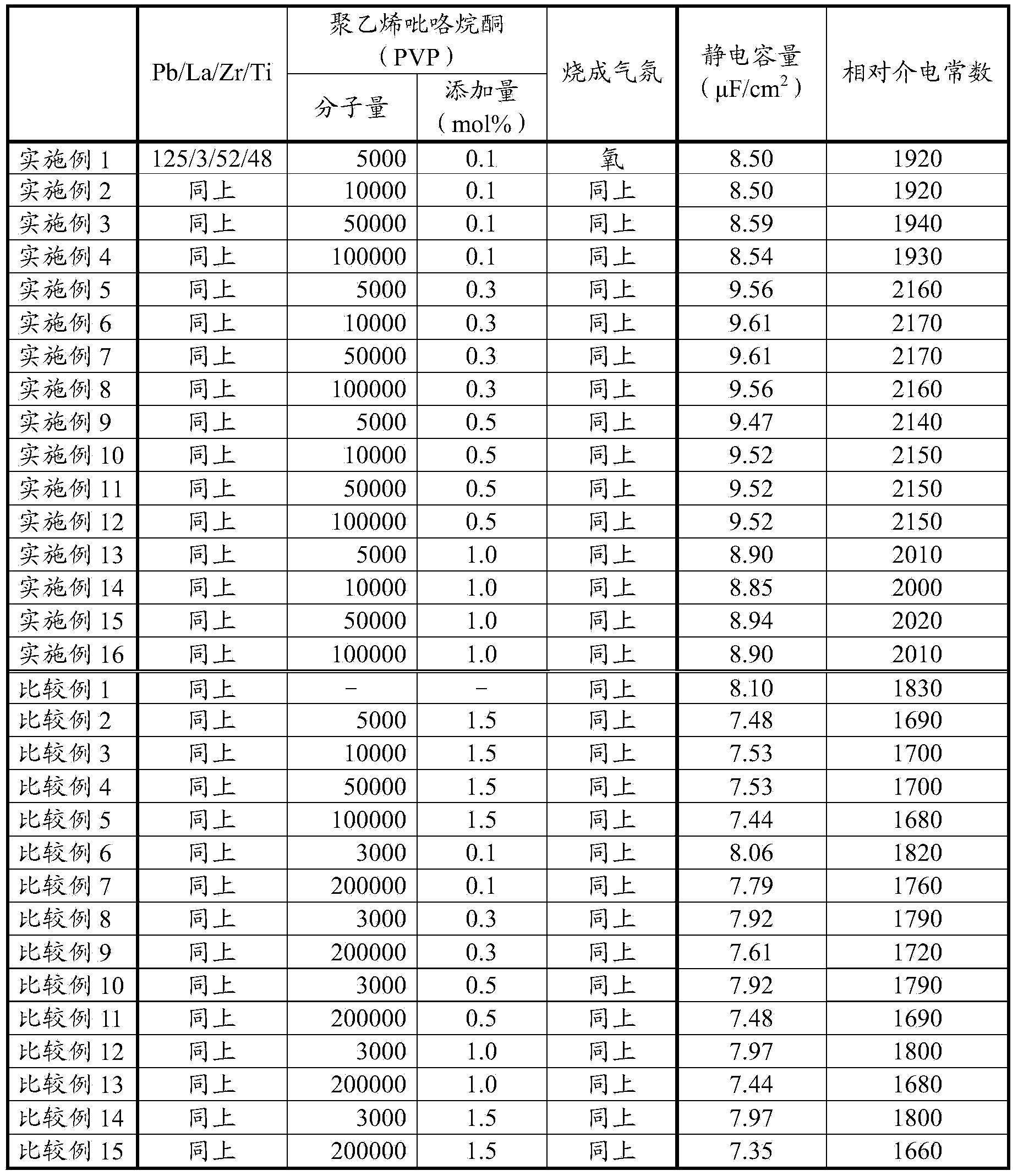

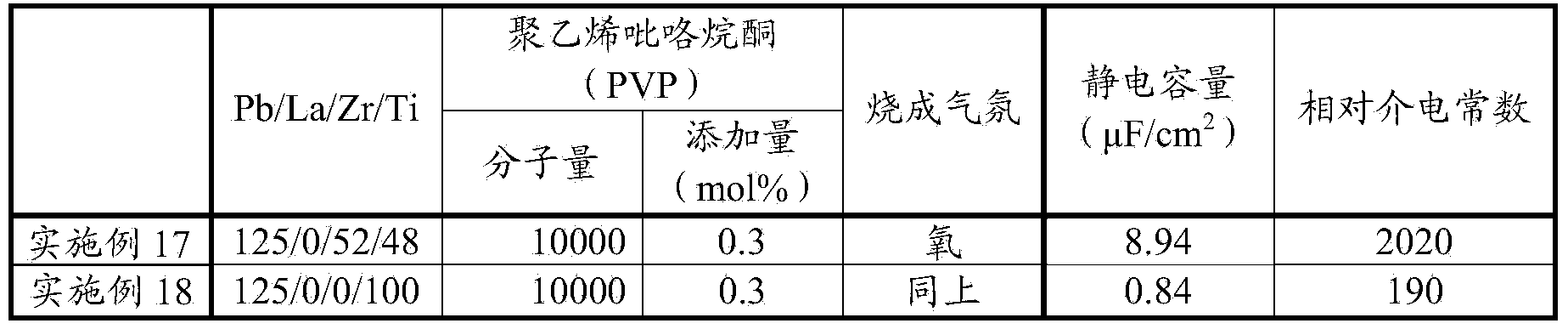

Composition for forming ferroelectric thin film, ferroelectric thin film and forming method thereof, and composite electronic assembly

ActiveCN103664169AIncrease capacityHigh densitySemiconductor/solid-state device manufacturingLiquid/solution decomposition chemical coatingLead zirconate titanateFerroelectric thin films

Cracking does not occur in a ferroelectric thin film even when Ce is not doped in a composition for forming ferroelectric thin films and a composition for forming relatively thick ferroelectric thin films contains lead acetate instead of lead nitrate. A ferroelectric thin film made of a titanate lead-based perovskite film or a titanate zirconate lead-based complex perovskite film is formed using the composition for forming ferroelectric thin films. The composition includes lead acetate, a stabilizing agent made of lactic acid and polyvinyl pyrrolidone. In addition, a monomer-equivalent molar ratio of polyvinyl pyrrolidone to a perovskite A site atom included in the composition is more than 0 to less than 0.015. Furthermore, a weight average molecular weight of the polyvinyl pyrrolidone is 5000 to 100000.

Owner:MITSUBISHI MATERIALS CORP

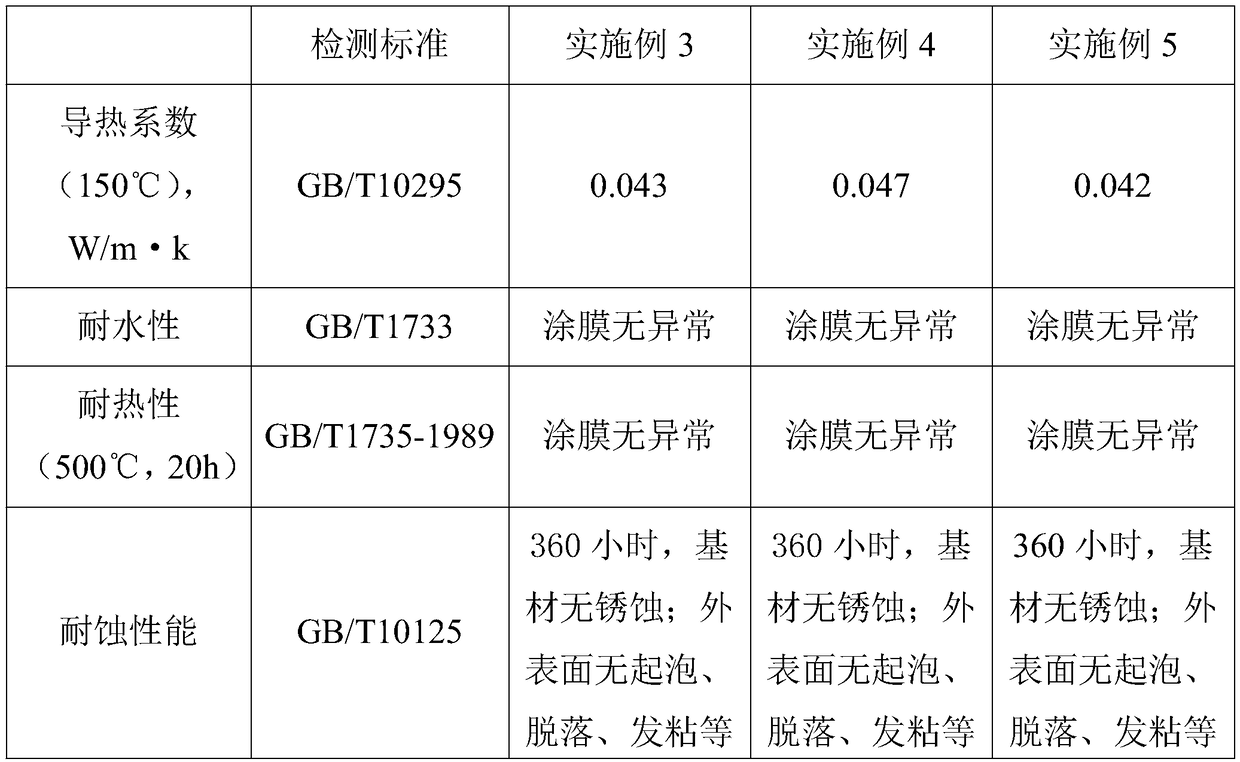

Nano anti-corrosion thermal insulation coating and preparation method thereof

InactiveCN109233555AMean free path reductionStrong scattering abilityAnti-corrosive paintsEpoxy resin coatingsFiberEpoxy

The invention discloses a nano anti-corrosion thermal insulation coating and a preparation method thereof; the nano anti-corrosion thermal insulation coating comprises the following components in parts by weight: 30 to 50 parts of epoxy resin, 6 to 12 parts of toughened resin, 5 to 10 parts of nano zirconia, 8 to 16 parts of silica aerogel, 5 to 10 parts of modified alumina silicate fibers, 0.5 to1.5 parts of benzomazole esters, 12 to 18 parts of nano perlite, 1 to 3 parts of a wetting dispersant, 1 to 3 parts of a thickener, 0.2 to 1 part of a defoaming agent, 2 to 5 parts of a curing agentand 20 to 30 parts of water; and the modified alumina silicate fibers are mainly prepared from alumina silicate fibers and chitosan by modification. The coating not only is good in thermal insulationeffect, but also is low in thermal conductivity and good in anti-corrosion effect.

Owner:安徽诺辰新型材料有限公司

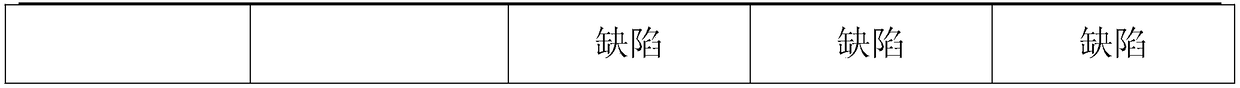

Artificial skin with high activity

ActiveCN105381503APromote regenerationGrowth inhibitionPeptidesTissue regenerationHigh activityPolymer

The invention discloses an artificial skin and a manufacturing method thereof. The artificial skin has the characteristics of good surface tension, plump and elastic texture, and bacterium inhibiting performance, and the tissue of the artificial skin is a polymer of nano chitosan and polypeptide. The artificial skin has the advantages of good biomedical characteristics, high medical value, short technical procedure, simple operation, less equipment, and reduced cost. The artificial skin has a good application prospect and application value.

Owner:青岛西凯生物技术有限公司

Infrared detector pixel and infrared detector based on CMOS process

PendingCN113720482AIncrease duty cycleLow thermal conductivityPyrometry using electric radation detectorsPhysical chemistryMetallic materials

The invention relates to an infrared detector pixel and an infrared detector based on a CMOS process, the pixel comprises a CMOS measurement circuit system and a CMOS infrared sensing structure located on the CMOS measurement circuit system, and the CMOS measurement circuit system and the CMOS infrared sensing structure are prepared by adopting the CMOS process; the CMOS infrared sensing structure comprises a reflecting layer, an infrared conversion structure and a plurality of columnar structures which are located on the CMOS measurement circuit system, the columnar structures are located between the reflecting layer and the infrared conversion structure, the reflecting layer comprises a reflecting plate and a supporting base, and the infrared conversion structure is electrically connected with the CMOS measurement circuit system through the columnar structures and the supporting base; the columnar structures adopt a non-metal solid column, the side wall of the non-metal solid column is made of a metal material, and a space surrounded by the side wall is filled with a non-metal material. According to the technical scheme, the problems that a traditional MEMS process infrared detector is low in performance, low in pixel scale, low in yield and the like are solved; meanwhile, the columnar structures adopt the non-metal solid column so that the structural stability can be improved, and the detection performance can be improved.

Owner:BEIJING NORTH GAOYE TECH CO LTD

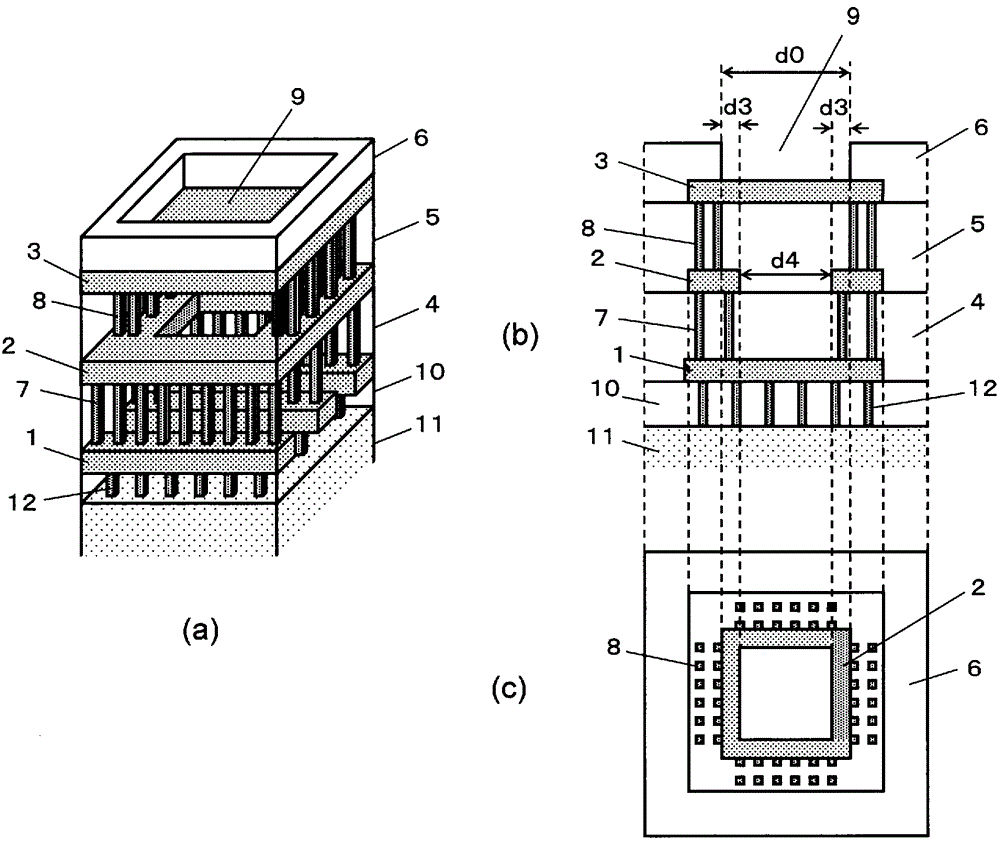

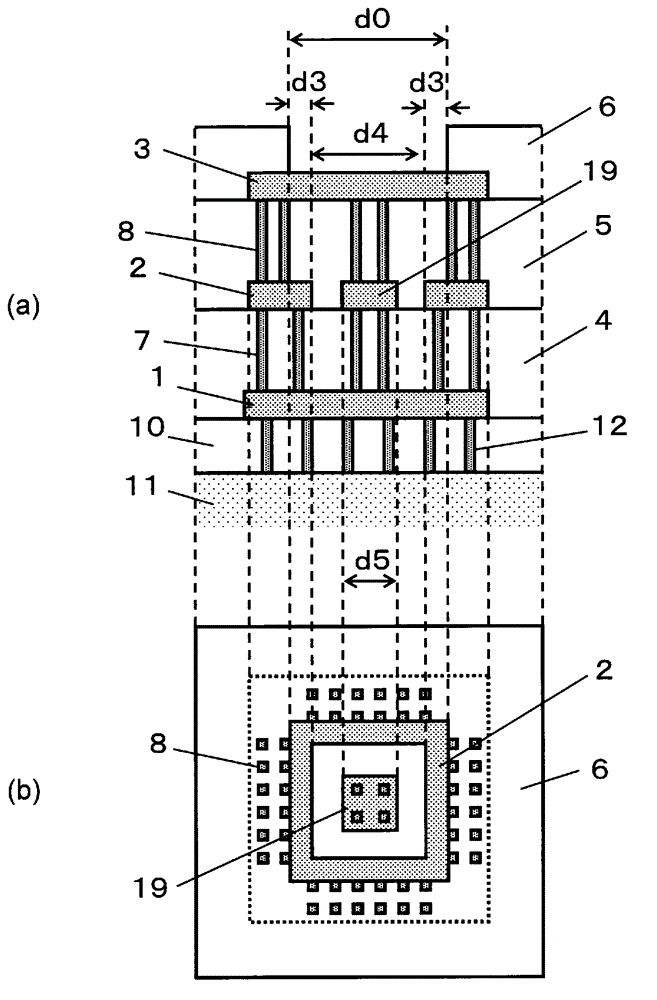

Semiconductor device

ActiveCN104350586AIncrease the areaReduce parasitic resistanceSemiconductor/solid-state device detailsSolid-state devicesChip sizeEngineering

In order to prevent chip size from being increased, while suppressing cracks below a pad opening, a protection film (6) has a pad opening (9) that exposes a part of a topmost layer metal film (3). The pad opening (9) is square, and the width of the opening is d0. A second metal film (2) has an opening below the pad opening (9). The opening is square, and the width of the opening is d4. The distance between the opening end of the protection film (6) and the opening end of the second metal film (2) is d3. The second metal film (2) has a rectangular ring shape, and protrudes to the inner side of the pad opening (9) by the distance d3.

Owner:SII SEMICONDUCTOR CORP

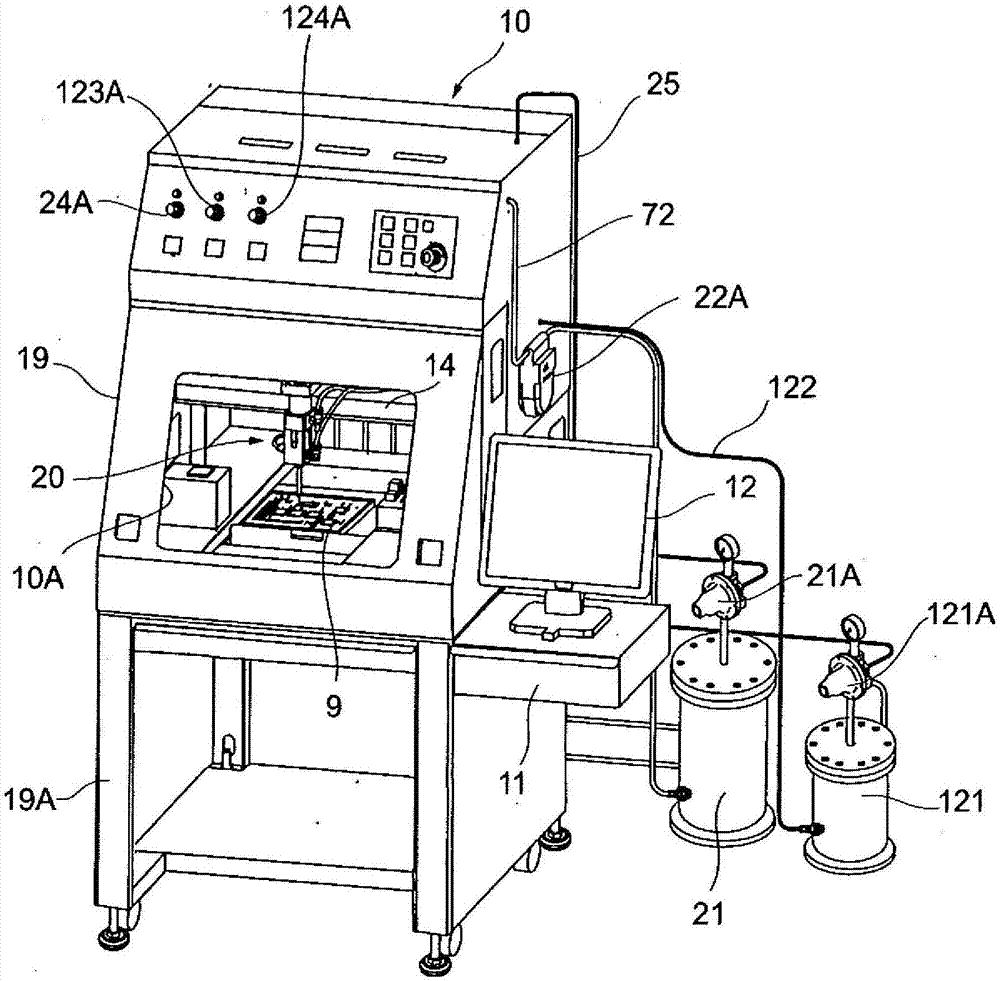

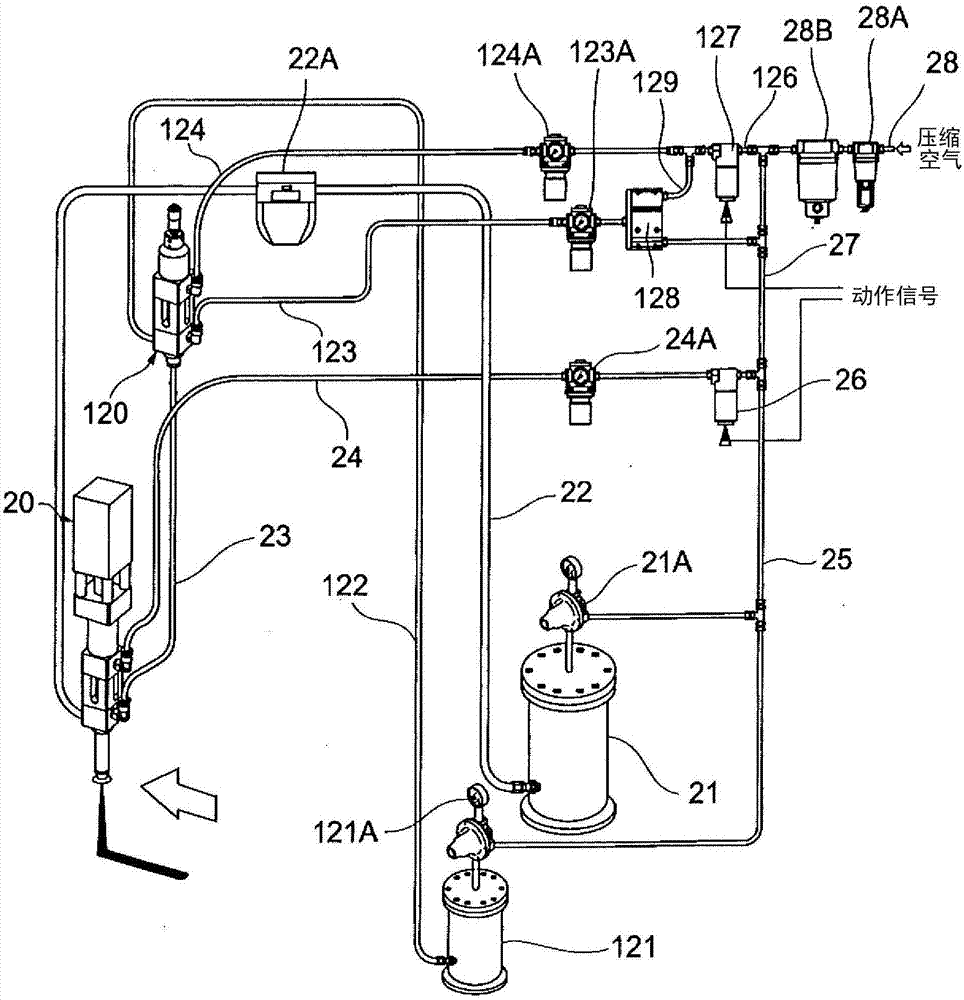

Apparatus and method for spray coating

ActiveCN107096661AAvoid drippingFilm thicknessLiquid surface applicatorsLiquid spraying apparatusSolventMaterial supply

The present invention relates to a spray coating apparatus and method by which a so-called drawing phenomenon does not occur even if a liquid coating material having high viscosity, such as stock solution, is used. The spray coating apparatus includes a spray gun (coating valve device) (20) having a discharge port for discharging the liquid coating material and an compressed air outlet for pelletizing the liquid coating material discharged from the discharge port; a liquid coating material supply device (21) for supplying a liquid coating material to the spray gun; and a compressed air supply device (120, 220) mixed with solvent mist and generating compressed air mixed with the solvent mist supplied to the compressed air outlet of the spray gun.

Owner:SHIMADA APPLI

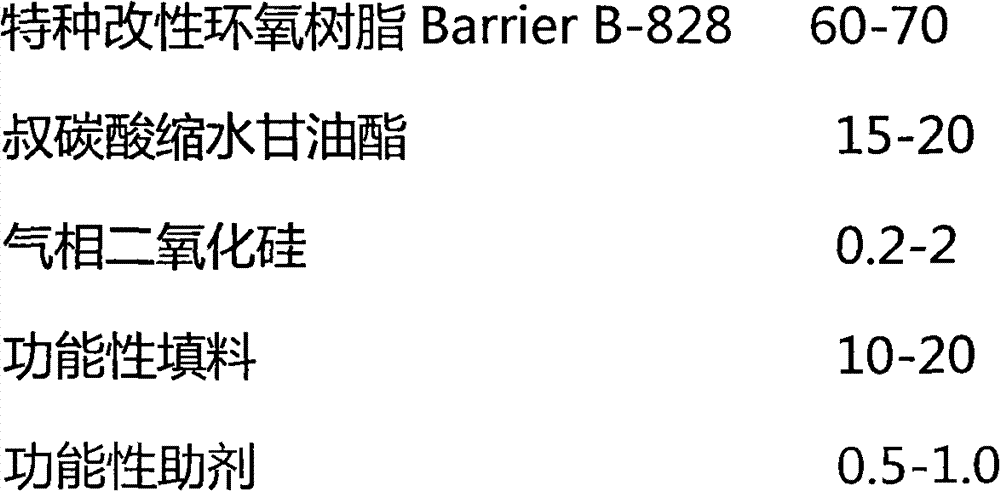

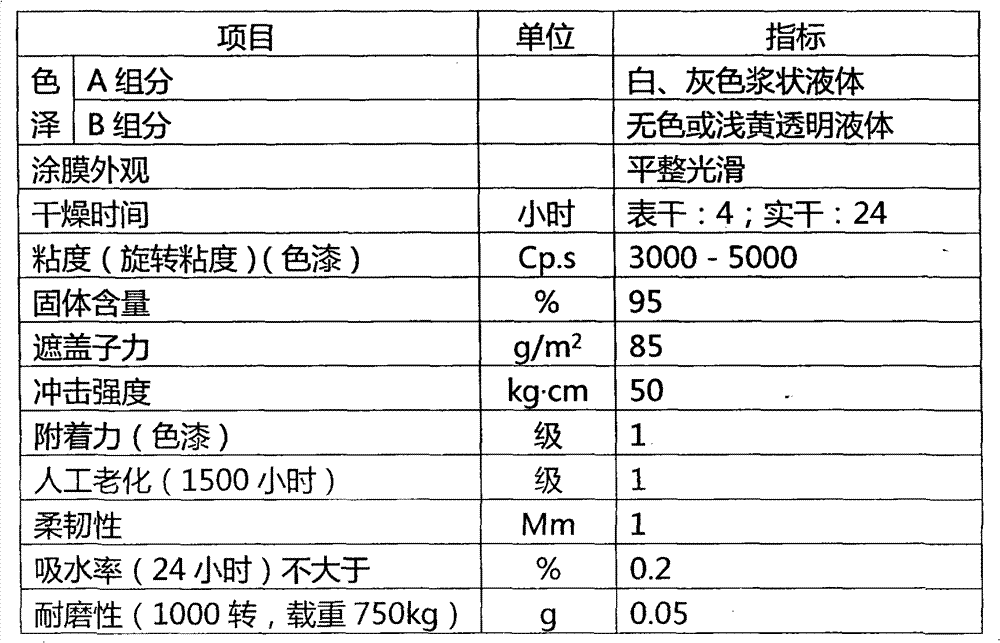

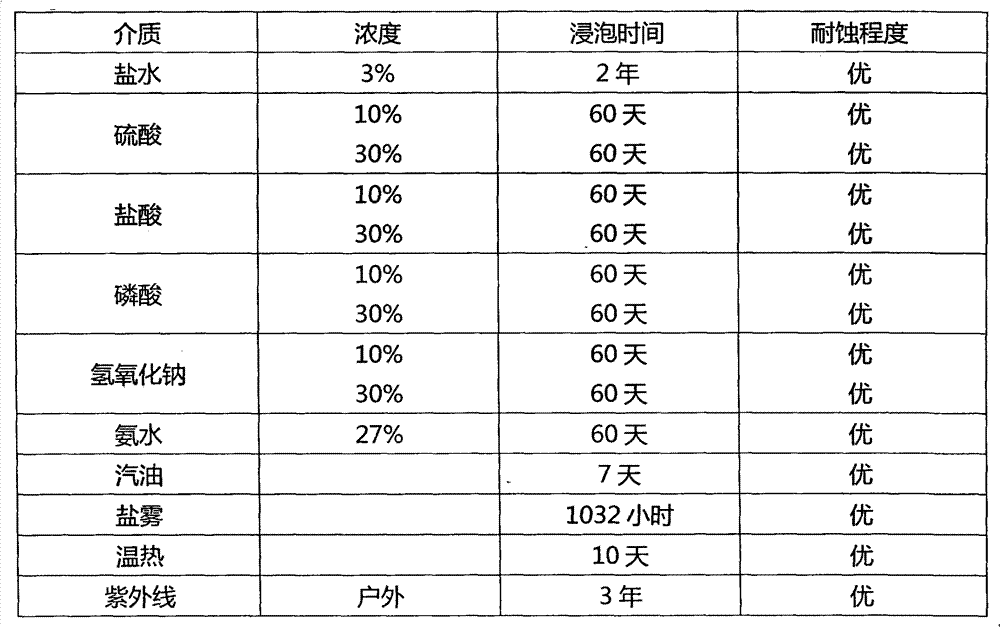

GZ-12 novel environmentally-friendly high-performance solvent-free epoxy coating and its preparation method

InactiveCN102952450AHigh environmental protection requirements cost-effectiveGood value for moneyAnti-corrosive paintsEpoxy resin coatingsEpoxyNon toxicity

The invention relates to a GZ-12 novel environmentally-friendly high-performance solvent-free epoxy coating and its preparation method, especially relates to a novel environmentally-friendly solvent-free epoxy coating and its preparation method, and belongs to the technical fields of a coating and its raw materials. The GZ-12 novel environmentally-friendly high-performance solvent-free epoxy coating is composed of a part A and a part B, wherein the part A comprises 60-70 parts by weight of a specific modified epoxy resin Barrier B-828, 15-20 parts by weight of Cardura E10P, 0.2-2 parts by weight of aerosil, 10-20 parts by weight of a functional filler, and 0.5-1.0 part of a functional assistant; the part B comprises 20-25 parts by weight of an alicyclic amine resin; and the weight ratio of the part A to the part B is 4-5:1. The GZ-12 novel environmentally-friendly high-performance solvent-free epoxy coating has the advantages of excellent resistances to the corrosion of acids, alkalis, salts, organic solvents and strong-oxidizability mediums, strong adhesion, good abrasion resistance, good flexibility, strong permeability, fast drying, simple construction, thick formed film, less application amount, non-toxicity, no benzene and the like, and is an ideal novel solvent-free epoxy anticorrosion coating which accords with environmental protection requirements and has a high cost performance.

Owner:许国良

Imitation electroplating silver paint

Owner:DANYANG JIAMEI CHEM

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com