Colored photosensitive resin composition

A technology of photosensitive resin and composition, which is applied in the direction of optics, optical filters, optical mechanical equipment, etc., can solve the problems of pattern shape deterioration, performance of colored photosensitive resin composition, unfavorable thick film, etc., and achieve good solubility , the effect of film thickness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0054] The preparation method of the pigment dispersion liquid is not particularly limited, and the pigment dispersion liquid of C.I. Pigment Green 58, C.I. Pigment Yellow 138, and C.I. 185 pigment dispersion and C.I. Pigment Yellow 138 pigment dispersion can also be prepared by (ii) mixing C.I. Pigment Green 58, C.I. Pigment Yellow 185 and C.I. Pigment dispersion of C.I. Pigment Yellow 185 and C.I. Pigment Yellow 138.

[0055] In addition, as the colorant (A), in addition to the above-mentioned C.I. Pigment Green 58, C.I. Pigment Yellow 185, and C.I. Pigment Yellow 138, known pigments and dyes can also be used. In the present invention, the total amount of C.I. Pigment Green 58, C.I. Pigment Yellow 185, and C.I. Pigment Yellow 138 in 100% by mass of the colorant (A) is preferably 50% by mass or more, more preferably 60% by mass or more, and furthermore It is preferably 70% by mass or more, particularly preferably 80% by mass or more, still more preferably 90% by mass or more...

Embodiment

[0303] Hereinafter, the present invention will be described more specifically with reference to the examples. The present invention is not limited by the following examples. It can be implemented with appropriate changes within the scope of the spirit described in the context. These are all included in the technology of the present invention. within range. In addition, below, unless otherwise specified, "part" means "mass part", and "%" means "mass %".

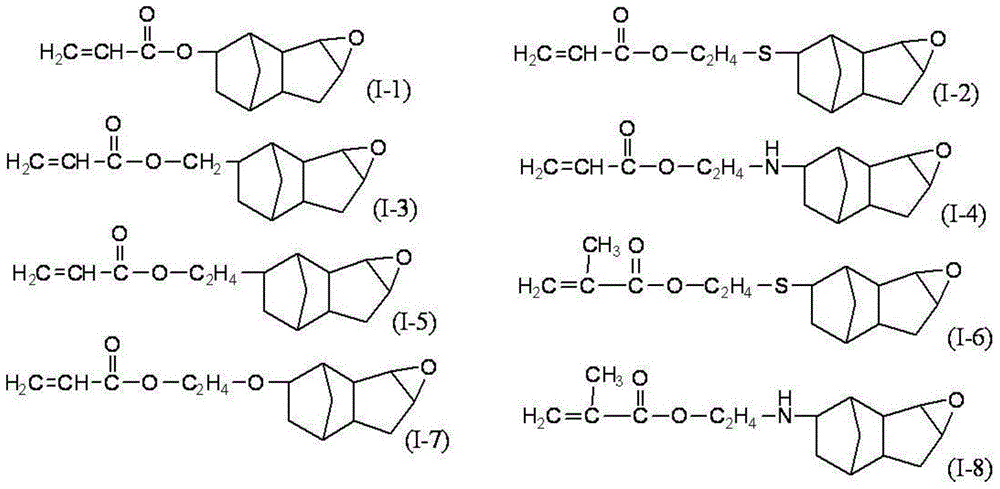

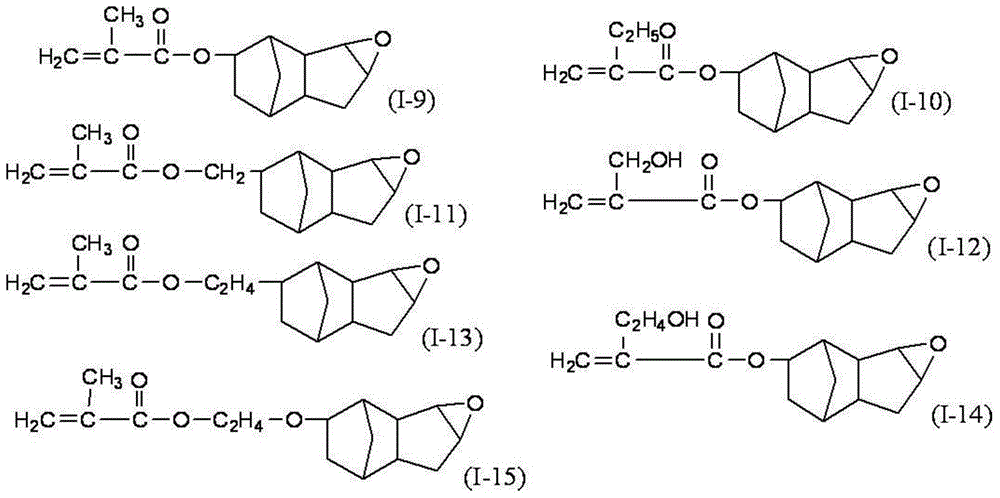

Synthetic example 1

[0305] Into a 1L flask equipped with a reflux cooler, a dropping funnel, and a stirrer, an appropriate amount of nitrogen gas was introduced to form a nitrogen atmosphere, and 280 parts by mass of propylene glycol monomethyl ether acetate was added, stirred and heated to 80°C. Next, 38 parts by mass of acrylic acid, 3,4-epoxytricyclic [5.2.1.0 2,6 ] A mixed solution of 289 parts by mass of a decan-8-yl and / or 9-yl ester mixture and 125 parts by mass of propylene glycol monomethyl ether acetate was dropped over 5 hours. On the other hand, a mixed solution obtained by dissolving 33 parts by mass of 2,2'-azobis(2,4-dimethylvaleronitrile) in 235 parts by mass of propylene glycol monomethyl ether acetate was dropped over 6 hours. After the dropwise addition, the same temperature was maintained for 4 hours, and then cooled to room temperature to obtain a copolymer having a type B viscosity (23° C.) of 125 mPa·s, a solid content of 37.0% by weight, and a solution acid value of 27 mg-...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| boiling point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com