Color filter layer and manufacture method thereof

A color filter layer and color filter technology, applied in the field of color filter layer, can solve problems such as insufficient light color purity and decline in display quality of thin-film transistor liquid crystal displays, achieve high color saturation, reduce material consumption, and save manufacturing processes cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

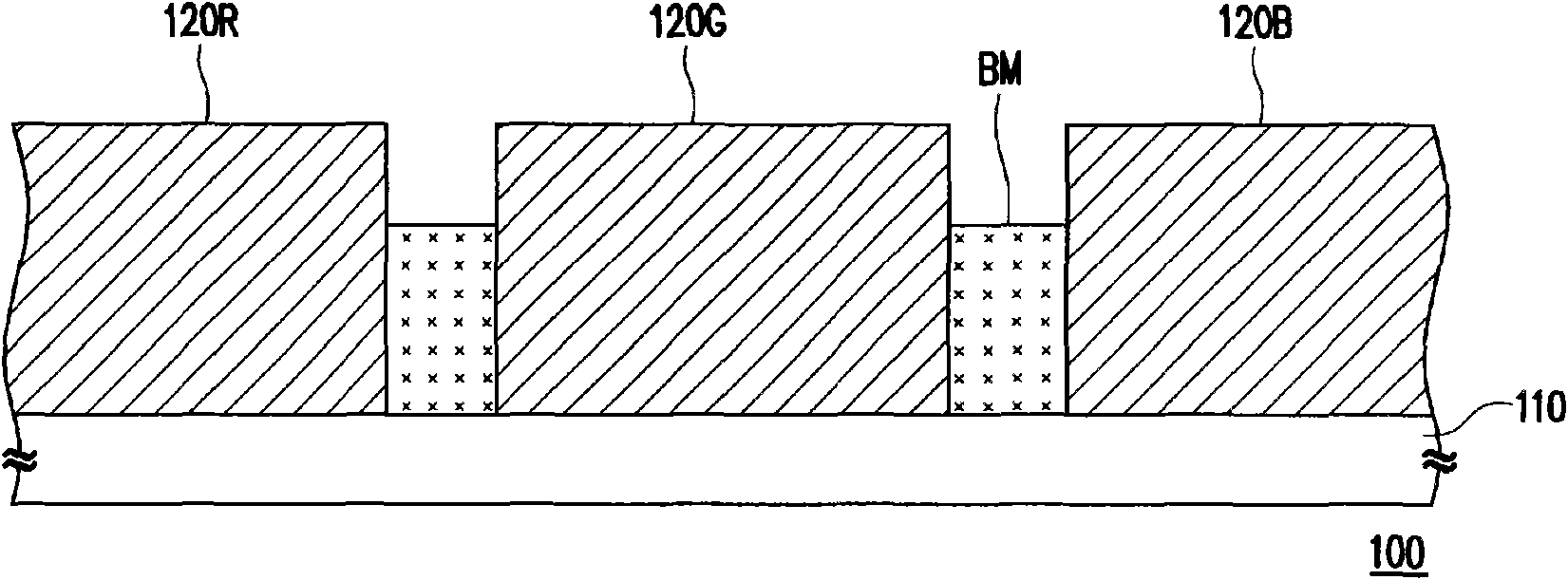

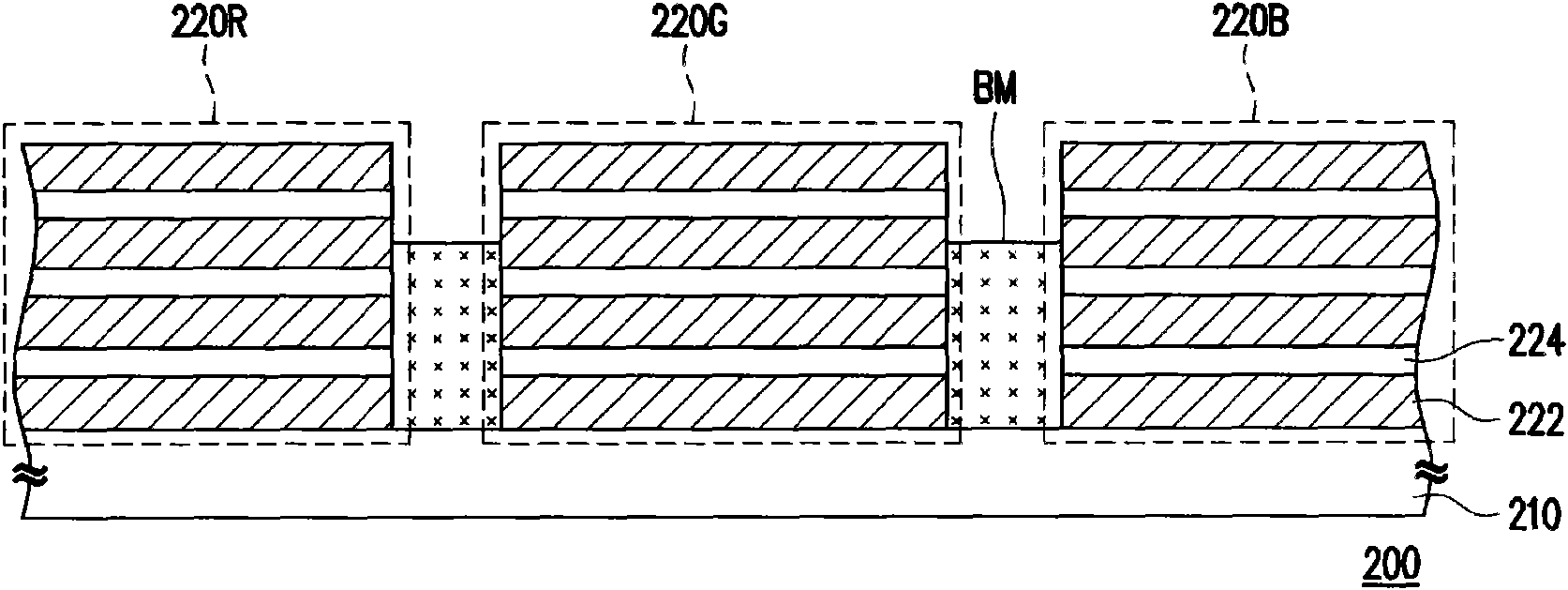

[0037] figure 2 It is a partial cross-sectional schematic diagram of a color filter layer according to the first embodiment of the present invention. Please refer to figure 2 , the color filter layer 200 of this embodiment includes a substrate 210 and a plurality of color filter stack patterns 220R, 220G, 220B, ..., wherein the color filter stack patterns 220R, 220G, 220B, ... are arranged on the substrate 210 on. In practice, the color filter stack patterns 220R, 220G, 220B, . . . may have different colors, such as red, green, blue, . In addition, the color filter layer 200 can be further provided with a black matrix pattern BM, so as to avoid color mixing of the color filter stack patterns 220R, 220G, 220B, . . . of different colors.

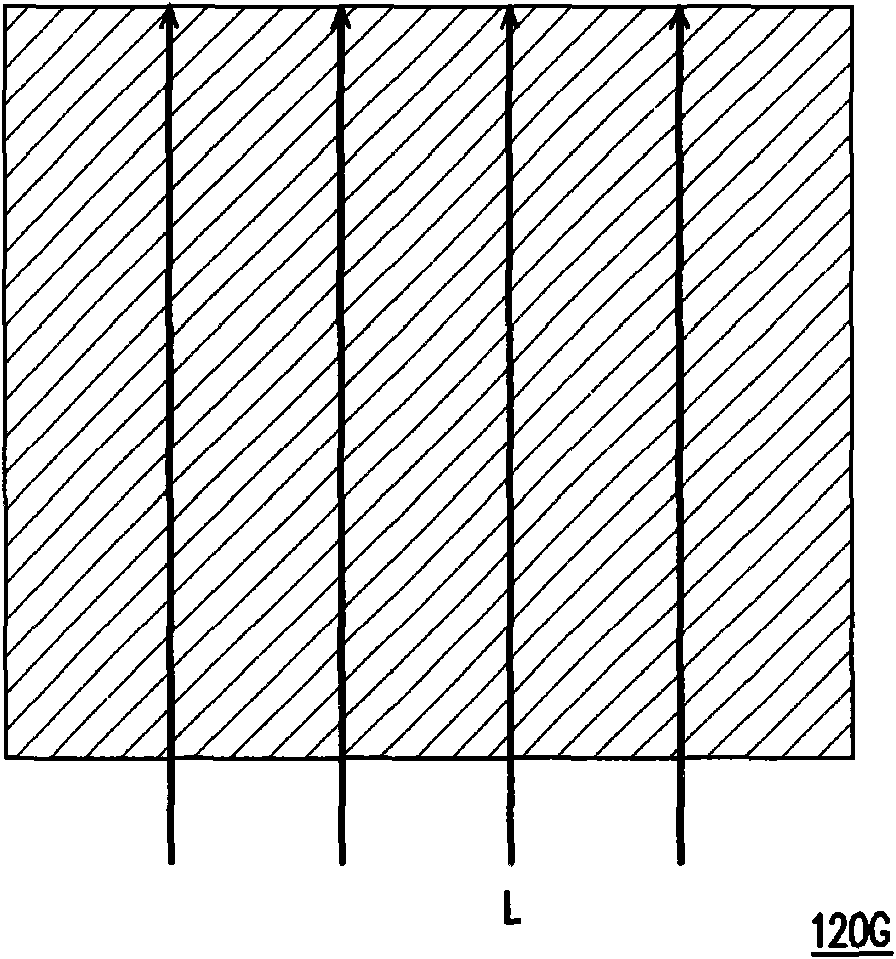

[0038] In this embodiment, each color filter stack pattern 220R, 220G, 220B, . . . includes two kinds of color filter films, and the two kinds of color filter films are stacked alternately. Specifically, as figure 2 as well as image ...

no. 2 example

[0055] Figure 8 It is a partial cross-sectional schematic diagram of a color filter layer according to the second embodiment of the present invention. The color filter layer 800 of this embodiment is similar to the color filter layer 200 of the first embodiment, but the main difference between them is that the modified color filter film in the color filter layer 800 of this embodiment is more It further includes a plurality of nano-glass balls. In addition, if the present embodiment and the first embodiment have the same or similar symbols, they represent the same or similar components, which will not be repeated here.

[0056] Please refer to Figure 8 The color filter layer 800 of this embodiment includes a substrate 210 and a plurality of color filter stack patterns 820R, 820G, 820B, . . . disposed on the substrate 210 . In practice, the color filter stack patterns 820R, 820G, 820B, . . . can have different colors, such as red, green, blue, . In addition, the color fil...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| refractive index | aaaaa | aaaaa |

| refractive index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com