Apparatus and method for spray coating

A technology of spraying device and supply device, which is applied in the direction of spraying device, liquid spraying device, and device for coating liquid on the surface. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

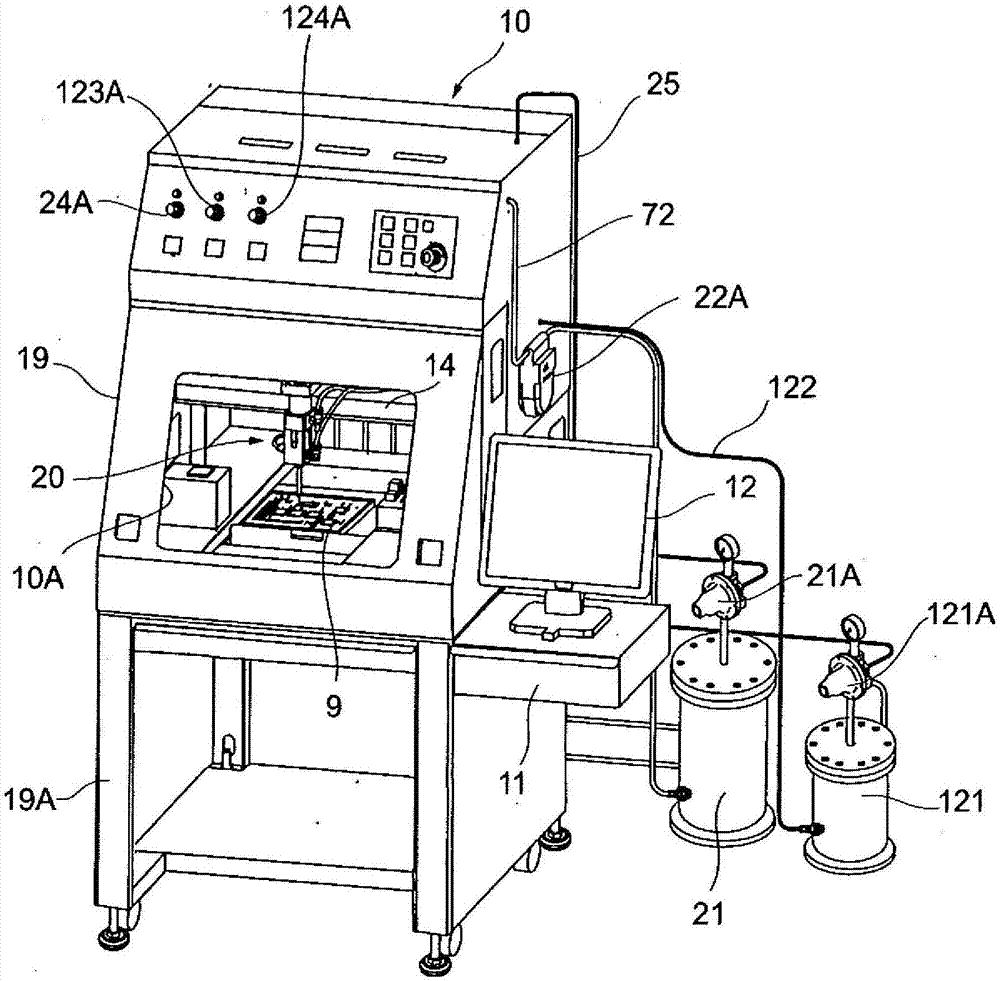

[0041] figure 1 It is a figure which shows the outline|summary of the whole structure of a spraying system.

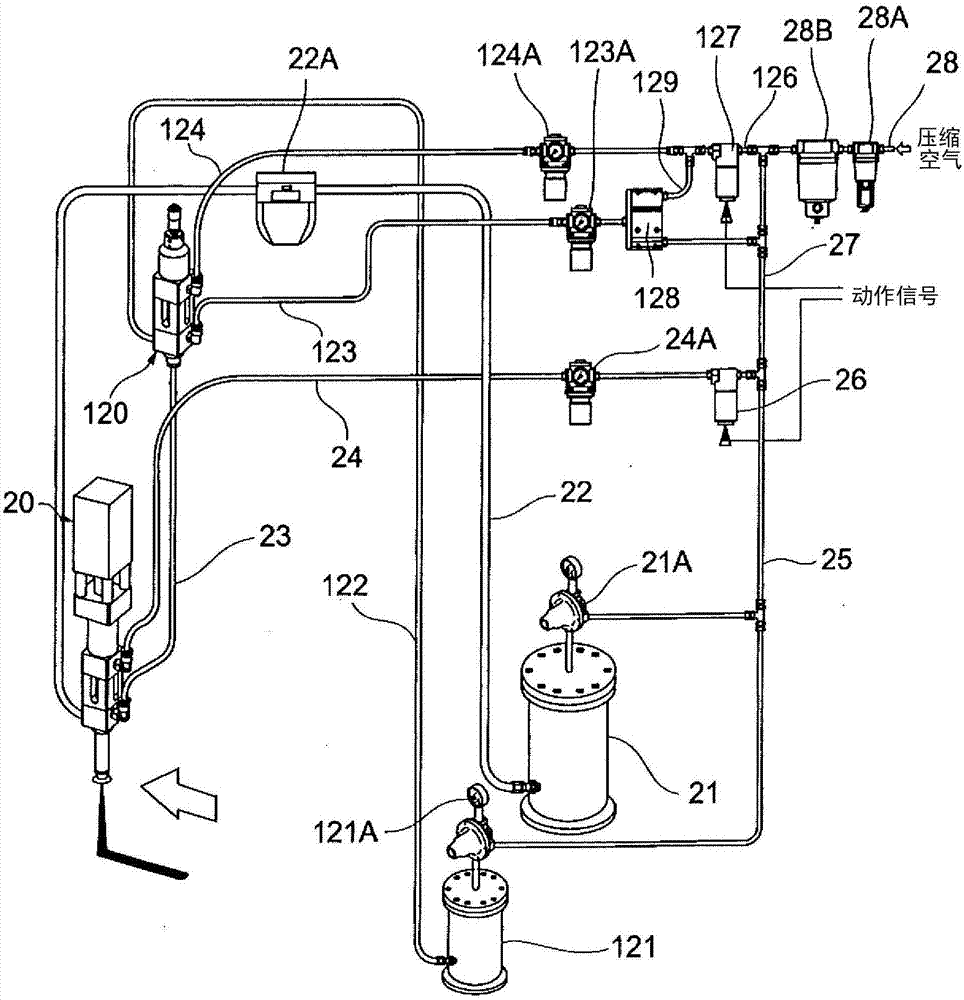

[0042] The casing 19 of the spraying system 10 is provided on a machine table 19A, and has a working port 10A at the front. The object 9 to be painted is placed in the casing 19 . A coating valve device 20 (spray gun (device)) is disposed above the object 9, and the coating valve device 20 is supported by the robot device 14 and is movable in three-dimensional directions of X, Y, and Z directions. A control panel, display lamps, compressed air pressure regulators 24A and 124 for operation, a compressed air pressure regulator 123A for atomization, etc. are arranged on the upper front surface of the casing 19 . A control device (computer, system) 11 and a CRT display device 12 are provided at a middle height position on the side surface of the casing 19 . A pressure feed tank (liquid coating material storage tank) 21 for a coating liquid and a pressure feed tank (solv...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com