Touch sensor wiring body, touch sensor wiring substrate, and touch sensor

A technology of touch sensor and wiring, which is applied in the direction of instrumentation, computing, and electrical digital data processing, etc. The effect of characteristic deterioration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

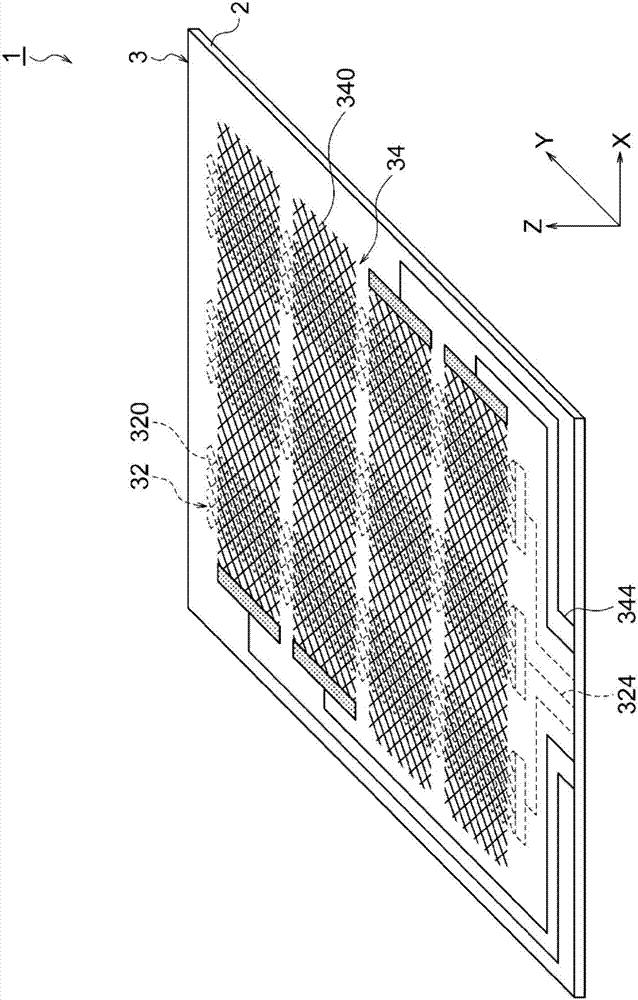

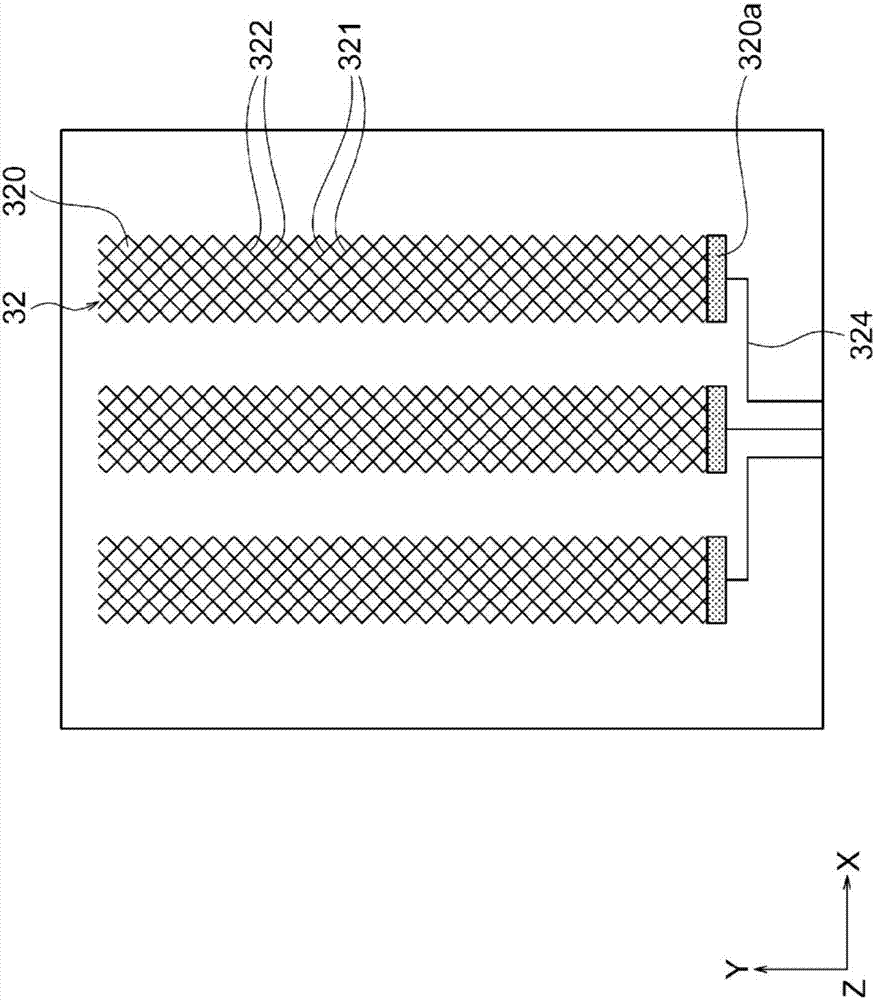

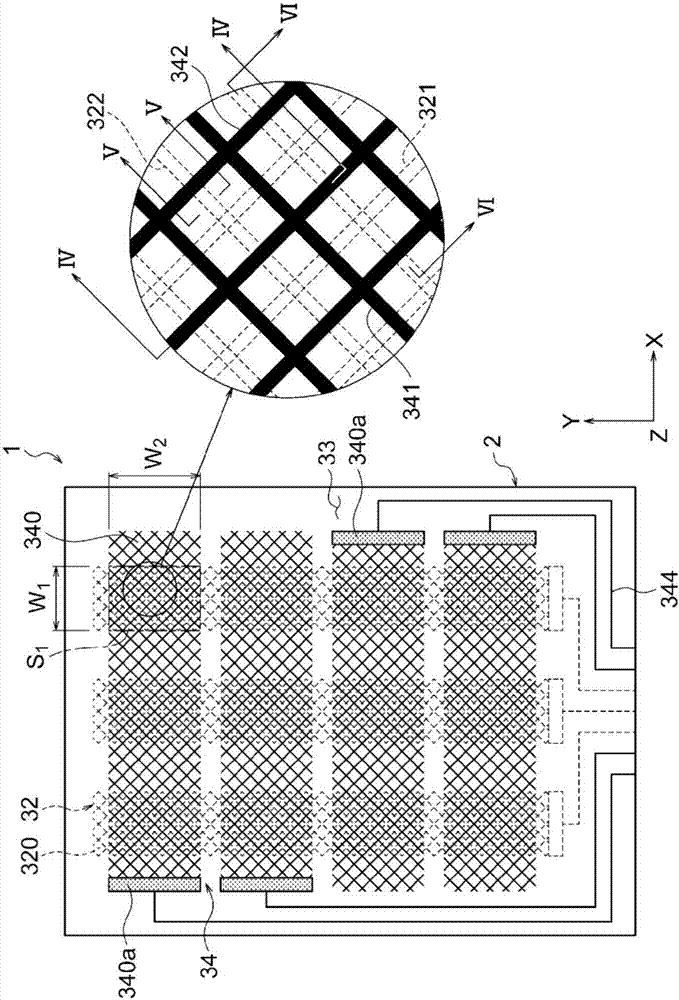

[0174] In Example 1, made Figure 1~4 The wiring board 1 for a touch sensor is shown. At this time, the thickness of the substrate 2 was formed to be 75 μm. The line width of the first conductor lines 321 and 322 constituting the first electrode pattern 320 of the first conductor layer 32 was 2 μm, and the line width of the lead 324 was 10 μm. The same applies to the second conductor layer 34 , and the line width of the second conductor lines 341 and 342 constituting the second electrode pattern 340 is 2 μm, and the line width of the lead 344 is 10 μm. The height (thickness) T of the first conductor line 321, 322 1 Formed to 3 μm. Similarly, the height (thickness) of the second conductor lines 341 and 342 is also formed to be 3 μm. As the substrate 2, a PET film was used, and as the conductive material 5, a thermosetting silver (Ag) paste was used. D as the first resin layer 31 1 The thickness is formed to be 15 μm, as the D of the second resin layer 33 2 The thickness ...

Embodiment 2

[0177] In Example 2, except that D of the second resin layer 33 2 The thickness was formed to be other than 25 μm, and a test sample was prepared in the same manner as in Example 1.

Embodiment 3

[0179] In Example 3, except that D of the first resin layer 31 1 The thickness was formed to be other than 50 μm, and a test sample was prepared in the same manner as in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com