Automatic paint sprayer

A sprayer and paint technology, applied in construction, building structure and other directions, can solve the problems of low effective utilization rate of artificial brushing paint, affecting surface quality and feel, uneven brushing thickness, etc., to improve working conditions, weight, etc. Lightweight, diluent-saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The invention discloses an automatic paint sprayer. The invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments:

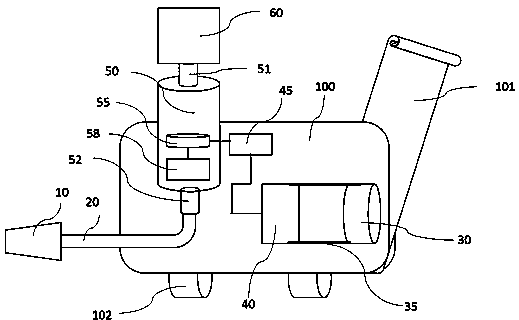

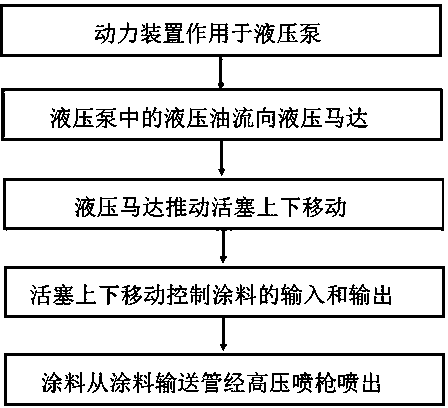

[0015] figure 1 It shows a schematic structural view of the automatic paint sprayer of the present invention, including a host housing 100, on which a handle 101 and two wheels 102 are connected to facilitate the flexible transfer of the automatic paint sprayer. The host housing also includes a paint delivery pipe 20 and a high-pressure spray gun 10 connected to the paint delivery pipe. A power unit 30 is arranged in the main unit housing 100. The power unit 30 of the present invention can be a gasoline engine or an electric motor. This embodiment selects an electric motor. The motor is connected to the power supply when the electric motor works, not shown in the figure. In specific work, the electric motor 30 is connected to a hydraulic pump 40 through a transmission belt 35 , and the hydraulic pu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com