Manufacturing method for pixel defining layer and manufacturing method for OLED device

A pixel-defining layer and manufacturing method technology, applied in semiconductor/solid-state device manufacturing, electric solid-state devices, semiconductor devices, etc., can solve the problems that limit the large-scale commercialization of OLED displays and high manufacturing costs, and achieve good insulation and service life. Long, stable effect of OLED material

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] In order to further illustrate the technical means adopted by the present invention and its effects, the following describes in detail in conjunction with preferred embodiments of the present invention and accompanying drawings.

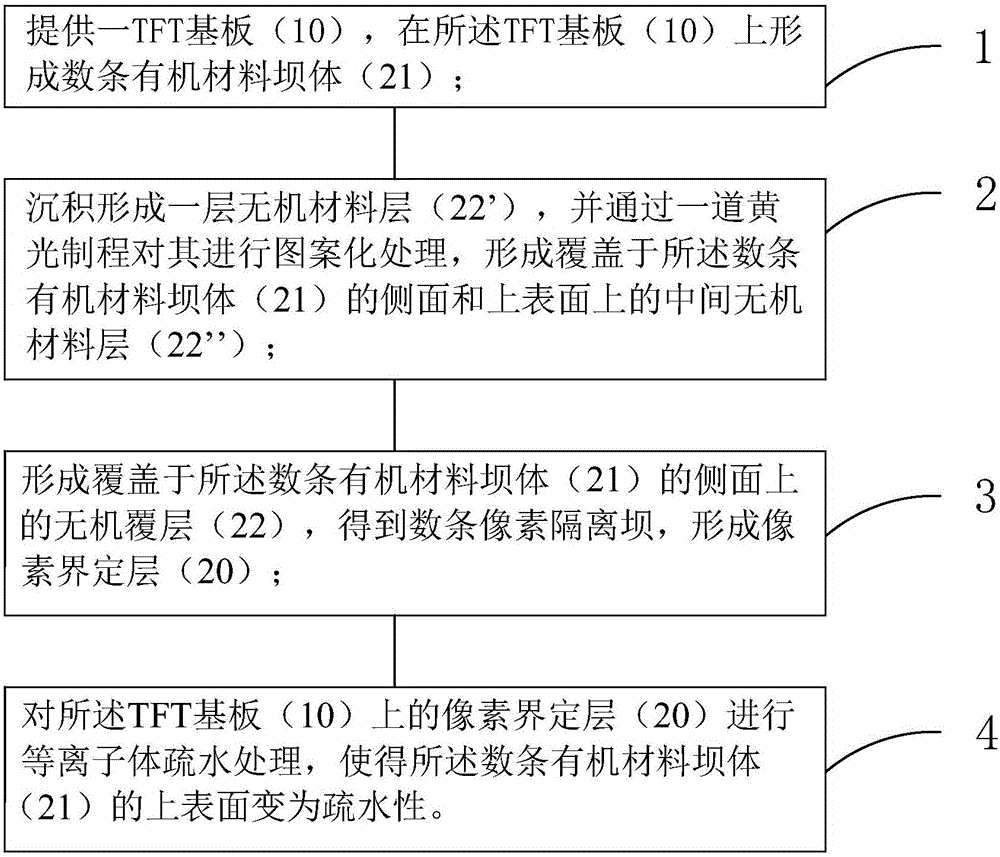

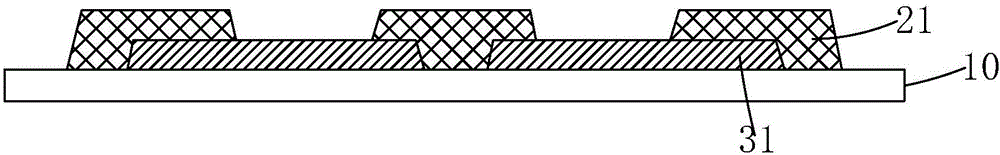

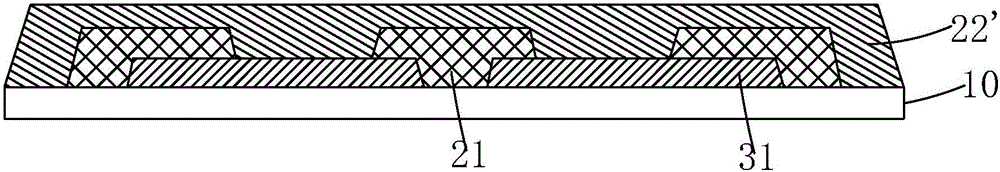

[0032] see figure 1 , the present invention firstly provides a method for manufacturing a pixel defining layer, comprising the following steps:

[0033] Step 1, such as figure 2 As shown, a TFT substrate 10 is provided, a layer of organic material is coated on the TFT substrate 10, and it is patterned through a yellow light process to form several organic material dams 21. The organic material The material dam 21 has side surfaces and an upper surface.

[0034] Specifically, the upper surface of the TFT substrate 10 provided in step 1 is provided with a first electrode 31 for constituting an OLED device, and the first electrode 31 is used as an anode or a cathode of the OLED device.

[0035] Specifically, in the step 1, the material of the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com