Composition for forming ferroelectric thin film, ferroelectric thin film and forming method thereof, and composite electronic assembly

A ferroelectric thin film and composition technology, which is applied in the direction of electrical components, circuits, capacitors, etc., can solve the problems of PZT thin film working hours increase, film cracking, etc., achieve high storage stability, reduce crystallization temperature, and improve composition uniformity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0037] The preparation method of the composition comprised in this way is demonstrated. For example, when preparing a composition for forming a PLZT film, first add a Zr compound (Zr source), a Ti compound (Ti source) and a stabilizer into a reaction vessel, and reflux in an inert atmosphere such as nitrogen at 80-200°C. The stabilizer is preferably contained in a ratio of 0.2 to 3 moles, more preferably in a ratio of 1 to 2 moles, based on 1 mole of the total amount of metals in the composition. That is, the stabilizer is contained so that (the number of molecules of the stabilizer) / (the number of atoms of the metal) is preferably 0.2-3, and more preferably 1-2. Among them, the reason why the mixing ratio of the above-mentioned stabilizer is limited to the range of 0.2 to 3 moles relative to 1 mole of the total amount of metals in the composition is that if it is less than 0.2 moles, the above-mentioned composition becomes insufficiently stable, so The storage stability of t...

Embodiment

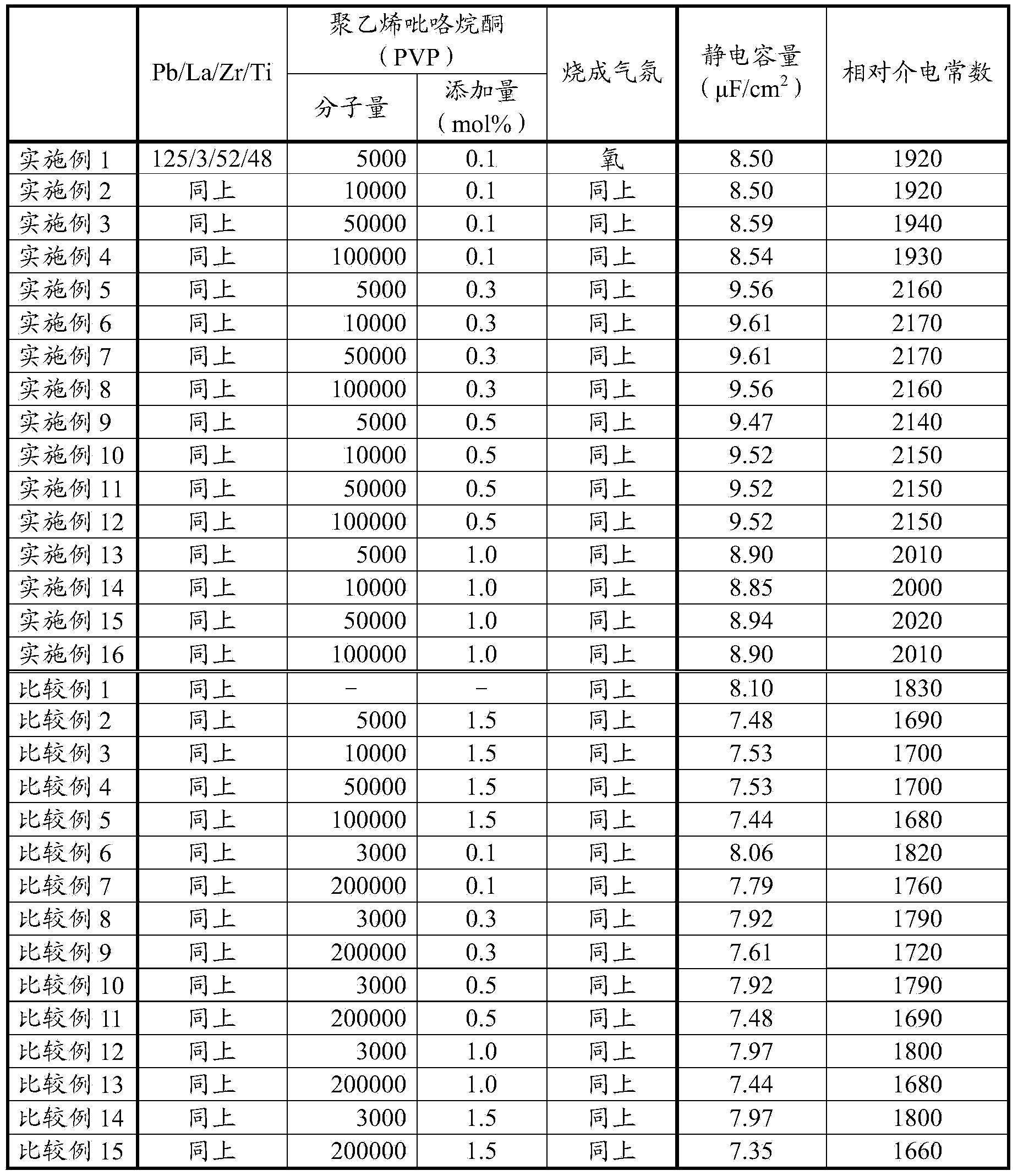

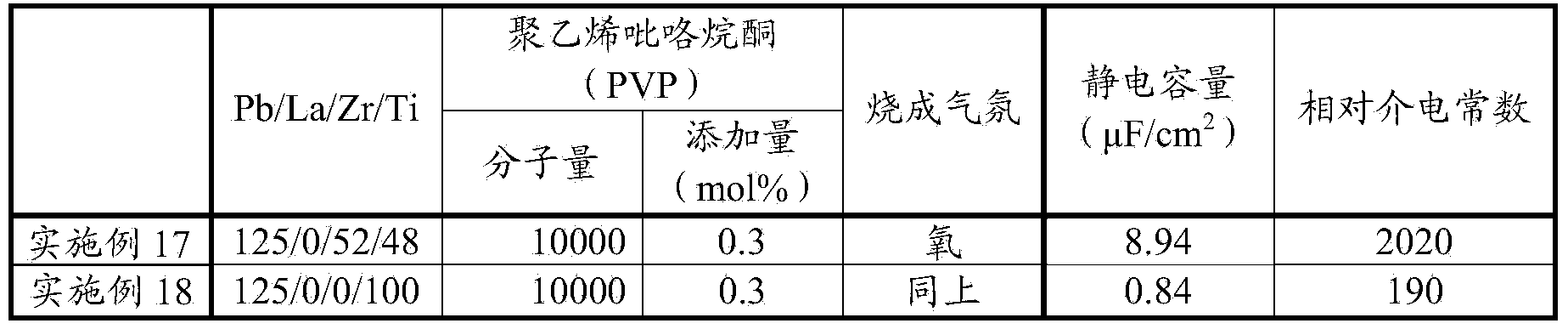

[0047] Next, examples of the present invention will be described in detail together with comparative examples.

[0048]

[0049] First, tetra-n-butoxyzirconium (Zr source), isopropoxytitanium (Ti source), and lactic acid (stabilizer) were added into the reaction vessel, and refluxed in a nitrogen atmosphere. Next, lead acetate trihydrate (Pb source) and lanthanum acetate 1.5 hydrate (La source) were added to this compound, and propylene glycol (solvent) was added, and refluxed in a nitrogen atmosphere, and by-products were removed by vacuum distillation, Diluting alcohol was added to this solution to obtain a composition 1 containing a metal compound having a ratio of each metal of Pb / La / Zr / Ti of 125 / 3 / 52 / 48 and a concentration of 10% by mass in terms of oxide. However, the mixing ratio of lactic acid (stabilizer) was 2 moles relative to 1 mole of the total amount of metals in the composition. To this composition 1, polyvinylpyrrolidone (weight average molecular weight: 500...

Embodiment 2~4

[0051] Added polyvinylpyrrolidone at an additional percentage of 0.1 mol% (monomer conversion) relative to 100 mol% of the PLZT molecules contained in the composition 1 in the composition 1, and the weight average molecular weight is 10000, 50000 and 100000, Except for this, thin films were formed on the substrates in the same manner as in Example 1. These thin films are referred to as Examples 2, 3 and 4, respectively.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com