Corrosion inhibitor resistant to H2S and CO2

A combined effect and corrosion inhibitor technology, applied in the direction of wellbore/well components, earthwork drilling and production, etc., can solve the problems of large fluctuations in chemical concentration, insignificant corrosion, and insufficient dosage, so as to reduce production costs and workers The effect of labor intensity, effectiveness or adaptability, and low emulsifying activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

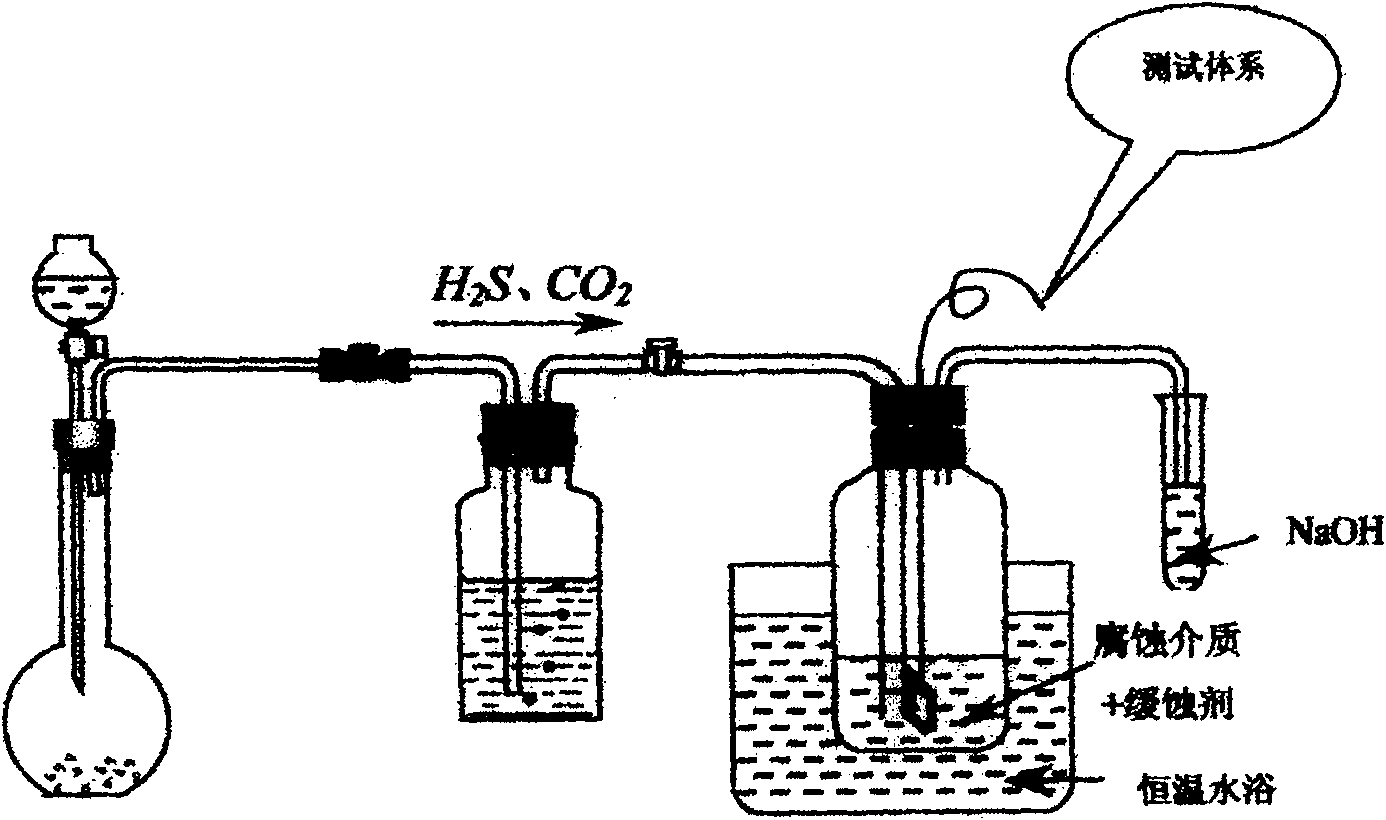

Method used

Image

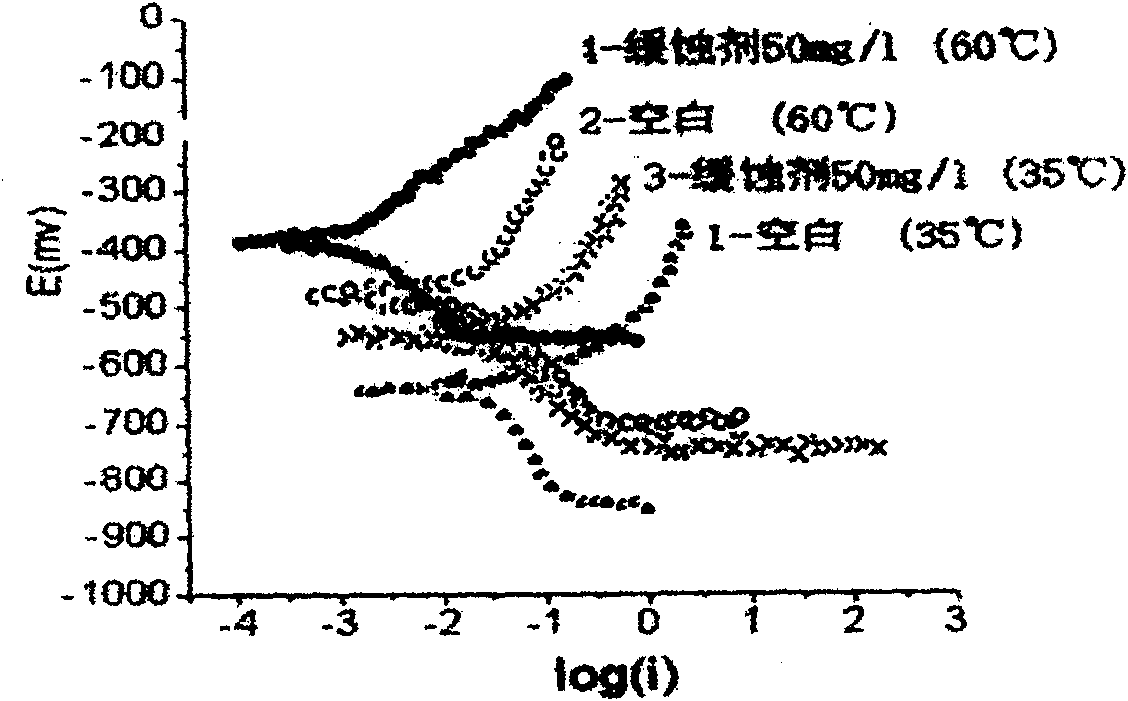

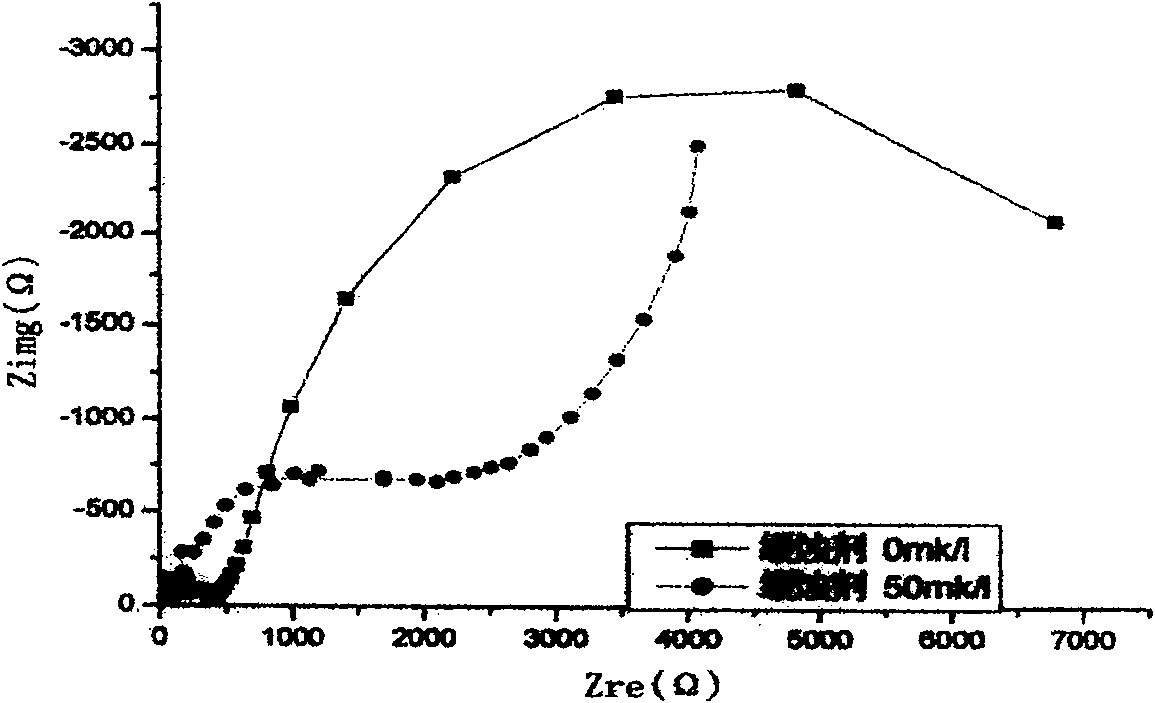

Examples

Embodiment 1

[0049] Embodiment 1: The corrosion inhibitor is made up of the following components by weight percentage: imidazoline quaternary ammonium compound 50%, alkynyloxymethyl quaternary ammonium salt 10%, isooctyl alcohol polyoxyethylene ether phosphate 10%, isopropanol 28.5%, fatty alcohol polyoxyethylene ether 0.5%, alkyl alcohol polyoxyethylene ether 1.0%.

[0050] The preparation method of the corrosion inhibitor is: according to the molar ratio of the above-mentioned naphthenic acid and diethylenetriamine naphthenic acid to prepare the imidazoline quaternary ammonium compound, the naphthenic acid and diethylenetriamine are sequentially added to the belt with stirring and distillation In the reactor of the device, react at 150±2°C for 3 hours, rapidly raise the temperature to 220°C, and vacuumize and dehydrate for 2 hours. Incubate at 5°C for 3 to 4 hours to obtain the intermediate of imidazoline quaternary ammonium compound; cool the above product to 100°C±2°C, take 50% of the ...

Embodiment 2

[0052] Embodiment 2: corrosion inhibitor is made up of the following components by weight percentage: imidazoline quaternary ammonium compound 80%, alkynyloxymethyl quaternary ammonium salt 5%, isooctyl alcohol polyoxyethylene ether phosphate 4.8%, isopropanol 10%, fatty alcohol polyoxyethylene ether 0.1%, alkyl alcohol polyoxyethylene ether 0.1%.

[0053] The preparation method of the corrosion inhibitor is basically the same as that of Example 1 except that the dosage is different.

Embodiment 3

[0054] Embodiment 3: The corrosion inhibitor is made up of the following components by weight percentage: imidazoline quaternary ammonium compound 60%, alkynyloxymethyl quaternary ammonium salt 8%, isooctyl alcohol polyoxyethylene ether phosphate 1%, isopropanol 30%, fatty alcohol polyoxyethylene ether 0.3%, alkyl alcohol polyoxyethylene ether 0.7%.

[0055] The preparation method of the corrosion inhibitor is basically the same as that of Example 1 except that the dosage is different.

PUM

| Property | Measurement | Unit |

|---|---|---|

| corrosion rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com