Photocuring finishing paint

A varnish, light-curing technology, applied in the direction of coating, can solve the problems of difficult to form excellent appearance, solvent resistance and recoating adhesion surface coating, etc., to achieve excellent adhesion and solvent resistance, vivid image. Good performance and high hardness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] Hereinafter, the technical solution of the present invention will be further described according to specific embodiments, but the present invention is not limited to these embodiments.

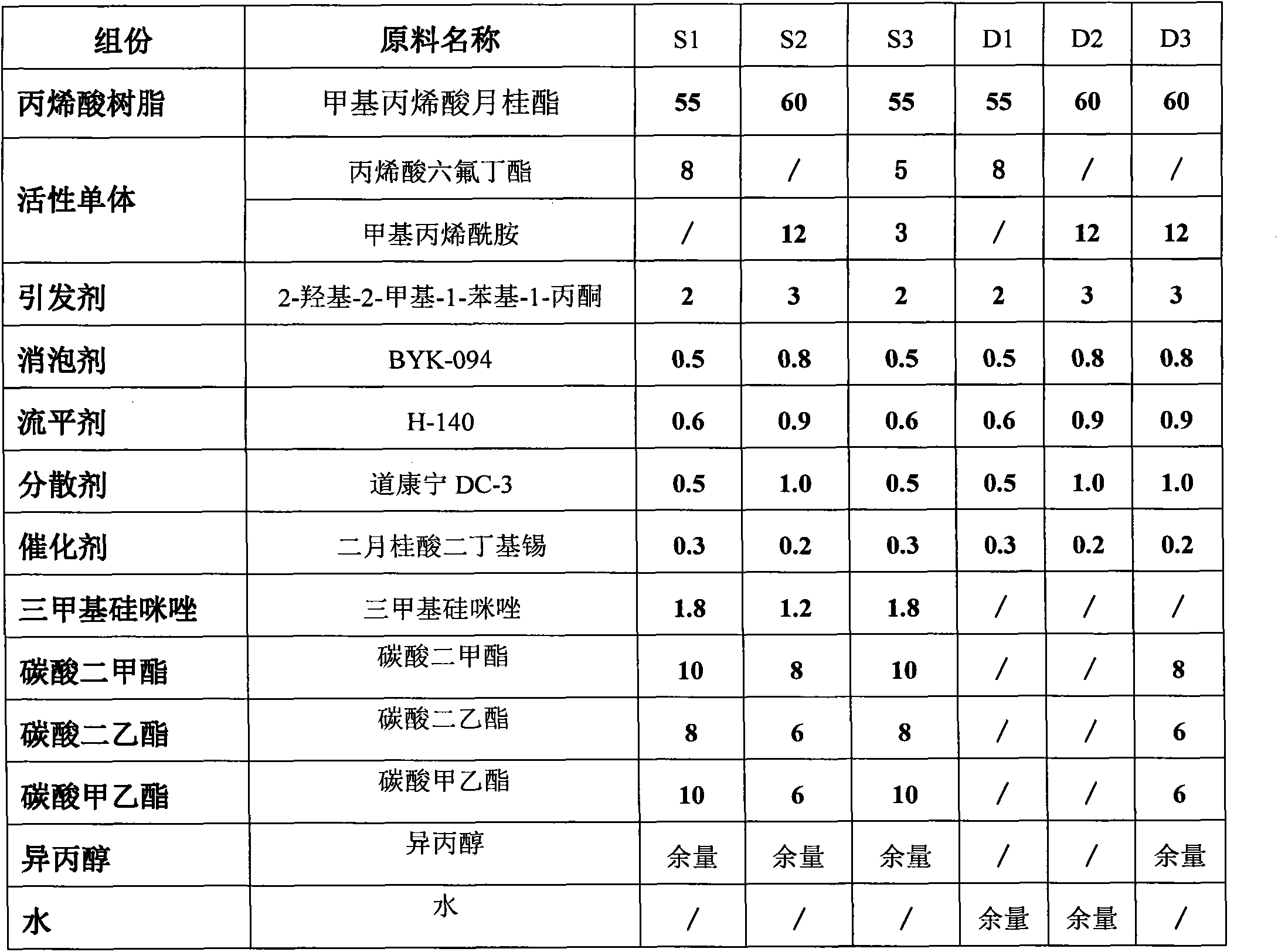

[0015] The photocurable varnish of the present invention includes the following components: acrylic resin: 55-65wt%, active monomer: 8-15wt%, photoinitiator: 2-5wt%, defoamer: 0.5-0.8wt %, leveling agent: 0.6-0.9wt%, dispersant: 0.5-1.0wt%, catalyst: 0.2-0.3wt%, trimethylsilimidazole: 1.2-1.8wt%, dimethyl carbonate: 6-10wt% , Diethyl carbonate: 6-8wt%, ethyl methyl carbonate: 6-12wt% and isopropanol: 2-12wt%.

[0016] Preferably, the light-curing varnish includes the following components: lauryl (meth)acrylate: 55-65wt%, hexafluorobutyl acrylate: 5-10wt%, methacrylamide: 3-5wt% , 2-Hydroxy-2-methyl-1-phenyl-1-acetone: 2-5wt%, BYK-094: 0.5-0.8wt%, H-140: 0.6-0.9wt%, Dow Corning DC-3: 0.5 -1.0wt%, dibutyltin dilaurate: 0.2-0.3wt%, trimethylsilimidazole: 1.2-1.8wt%, dimethyl carbonate: 6-10wt...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com