Dedusting equipment and technology for combustible dust environment

A kind of dust removal equipment and dust technology, applied in the field of aluminum powder, can solve problems such as lack of understanding, personal injury, economic loss, etc., achieve the effect of facilitating recycling and reuse, and reducing the possibility of explosion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The invention will be described in detail below in conjunction with the accompanying drawings, but it should be pointed out that the implementation of the present invention is not limited to the following embodiments.

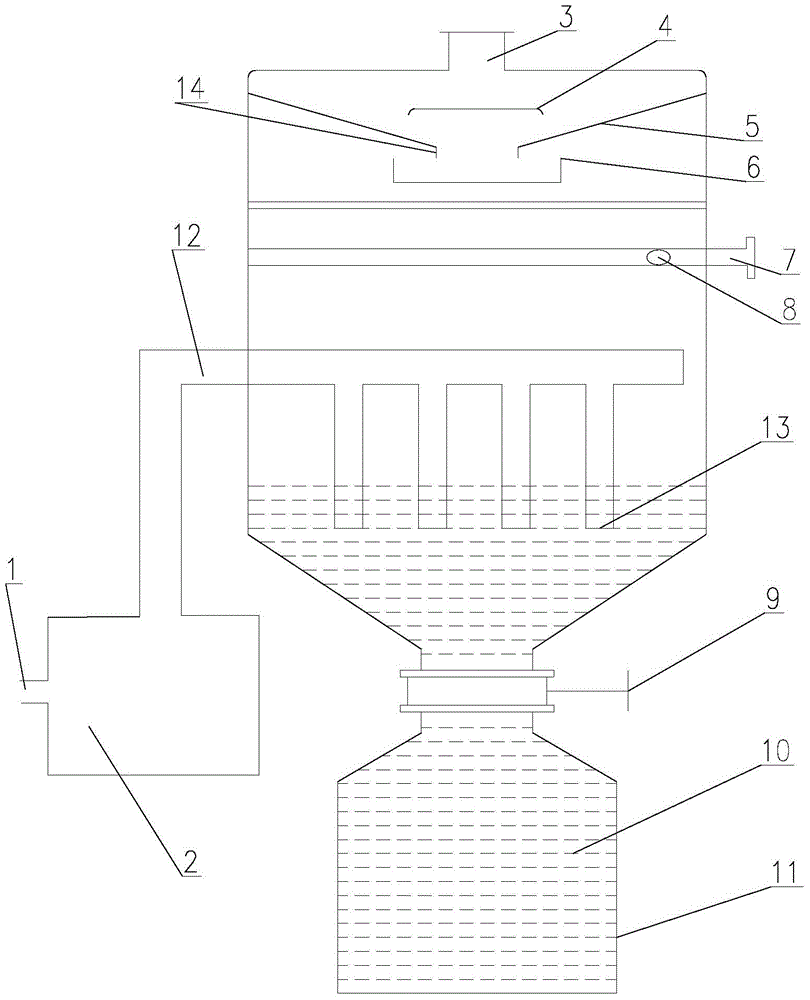

[0021] A kind of dedusting equipment for combustible dust environment, comprising a dust suction device, a dust removal tank, a discharge valve 9, and a collecting tank 11, the air outlet pipe 12 of the dust suction device is arranged in the dust removal tank, and the outlet pipe 12 The tuyere 13 stretches in the white oil 10 (liquid paraffin) in the dust removal tank, and the collection tank 11 is connected to the lower end of the dust removal tank by the discharge valve 9, and the white oil 10 (liquid paraffin) is housed at the lower end of the dust removal tank. White oil 10 is filled in feed tank 11.

[0022] The dust removal tank includes a dust removal tank body, a clean gas outlet 3, a baffle plate 4, a liquid collection ring 5, a liquid collectio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com