Polyvinyl chloride card matrix materials for production of noncontact IC card and method for making same

A polyvinyl chloride, non-contact technology, applied in the production of polyvinyl chloride card-based materials for non-contact IC cards and its preparation field, can solve the problems of poor light-shielding performance, large amount of rutile titanium dioxide, and high price

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] Embodiment 1: making non-contact IC card polyvinyl chloride card base material

[0027] 1. Preparation,

[0028] Weigh 750kg of polyvinyl chloride powder, 80kg of anatase titanium dioxide, 80kg of nano calcium carbonate, 0.6kg of aluminum powder, 64.4kg of reinforcing agent, 15kg of thermal stabilizer and 10kg of lubricant.

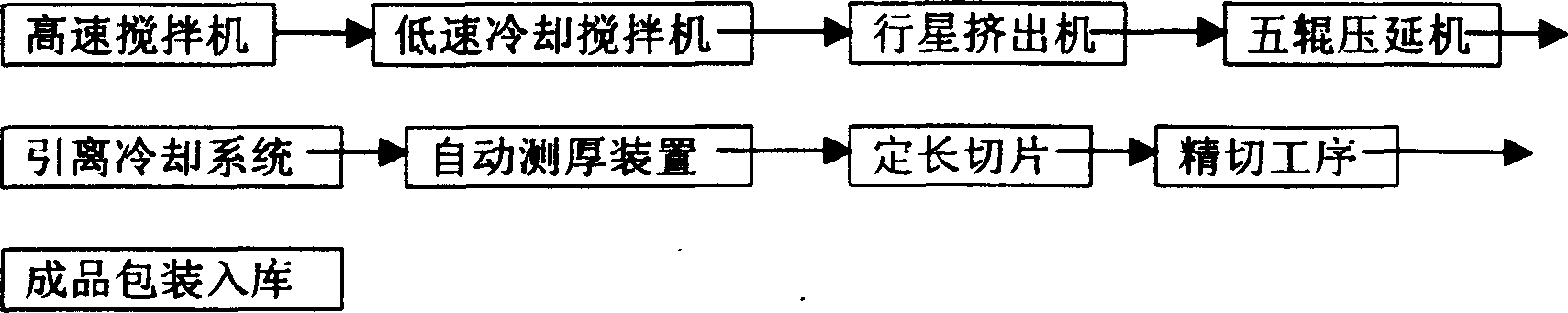

[0029] 2. Processing technology:

[0030] 1. Stir the molten material at high speed. Put the above-mentioned raw materials into the high-speed mixer according to the proportion, fully stir and mix evenly, and stir until the material temperature is 105-115°C;

[0031] 2. Stir and cool the material at a low speed. Discharge the high-speed stirred material to a low-speed cooling mixer for cooling and stirring, so that the temperature of the material drops to 40-45°C;

[0032] 3. Plasticization of extruder: Evenly input the cooled material into planetary extruder for plasticization, and the temperature of planetary extruder is controlled at 155-165°C...

Embodiment 2

[0038] The difference between embodiment 2 and embodiment 1 is that the proportioning of each raw material is different: 800kg of polyvinyl chloride powder, 60kg of anatase titanium dioxide, 60kg of nano calcium carbonate, 0.4kg of aluminum silver powder, 50kg of reinforcing agent, heat stabilizer 14.6kg and lubricant 15kg. All the other are with embodiment 1.

Embodiment 3

[0040] The difference between embodiment 3 and embodiment 1 is that the proportioning of each raw material is different: 755kg of polyvinyl chloride powder, 70kg of anatase titanium dioxide, 70kg of nano-calcium carbonate, 0.5kg of aluminum silver powder, 80kg of reinforcing agent, heat stabilizer 10kg and lubricant 14.5kg. All the other are with embodiment 1.

[0041] The reinforcing agent is a copolymer of methyl methacrylate, butadiene and styrene, code-named MBS. The heat stabilizer is octyltin mercaptide, the model is 17MOK-N. The lubricant is stearic acid. The fineness of aluminum powder is 280 mesh superfine aluminum powder. The fineness of nano calcium carbonate is 80 nanometers.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com